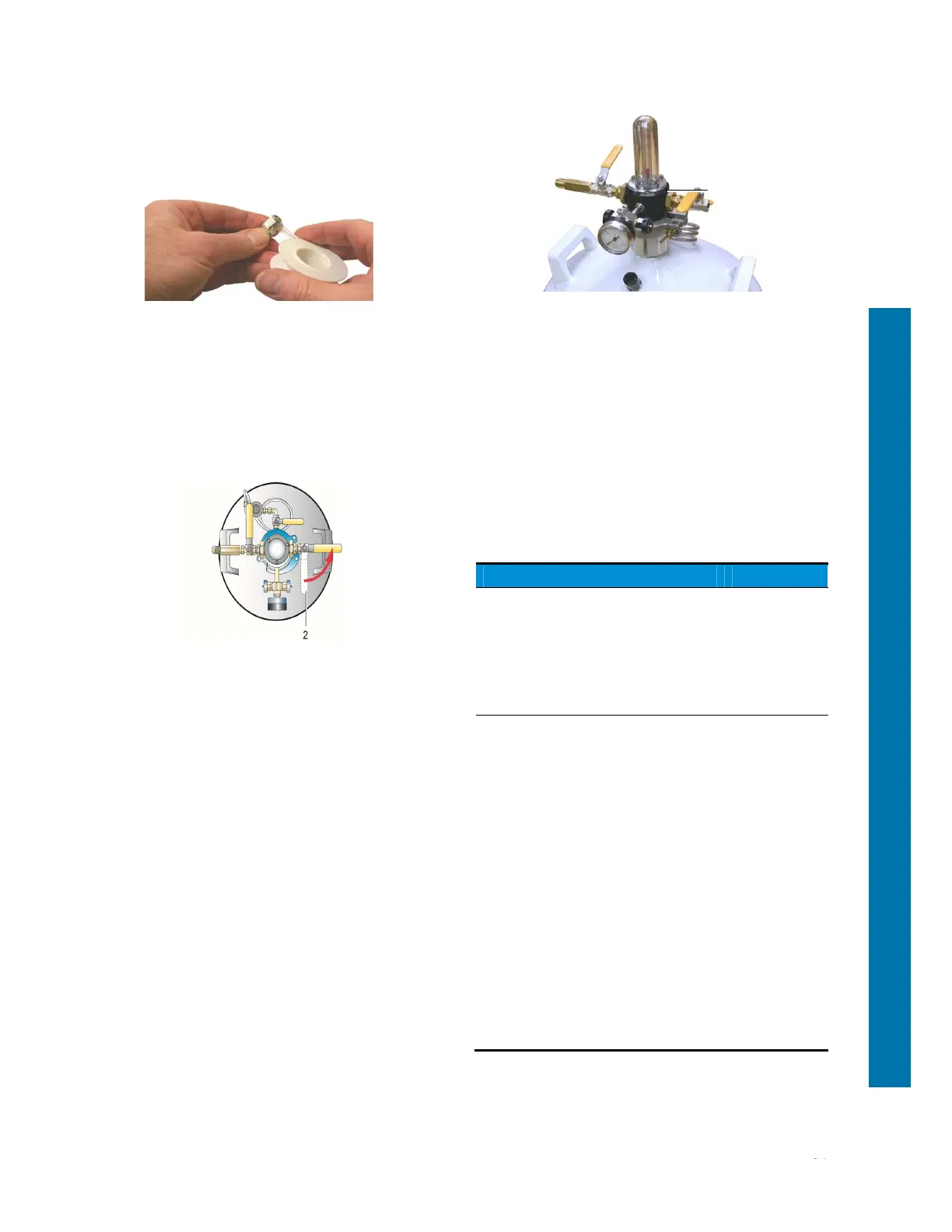

3. Apply PTFE tape or joint filler (silicone etc.) to the

threads of the replacement part, taking care not to

obstruct the orifices.

4. Screw the part in, keeping tight control so as not to

damage the threads.

5. Test for leaks (see§ 9.3.4, on page 29).

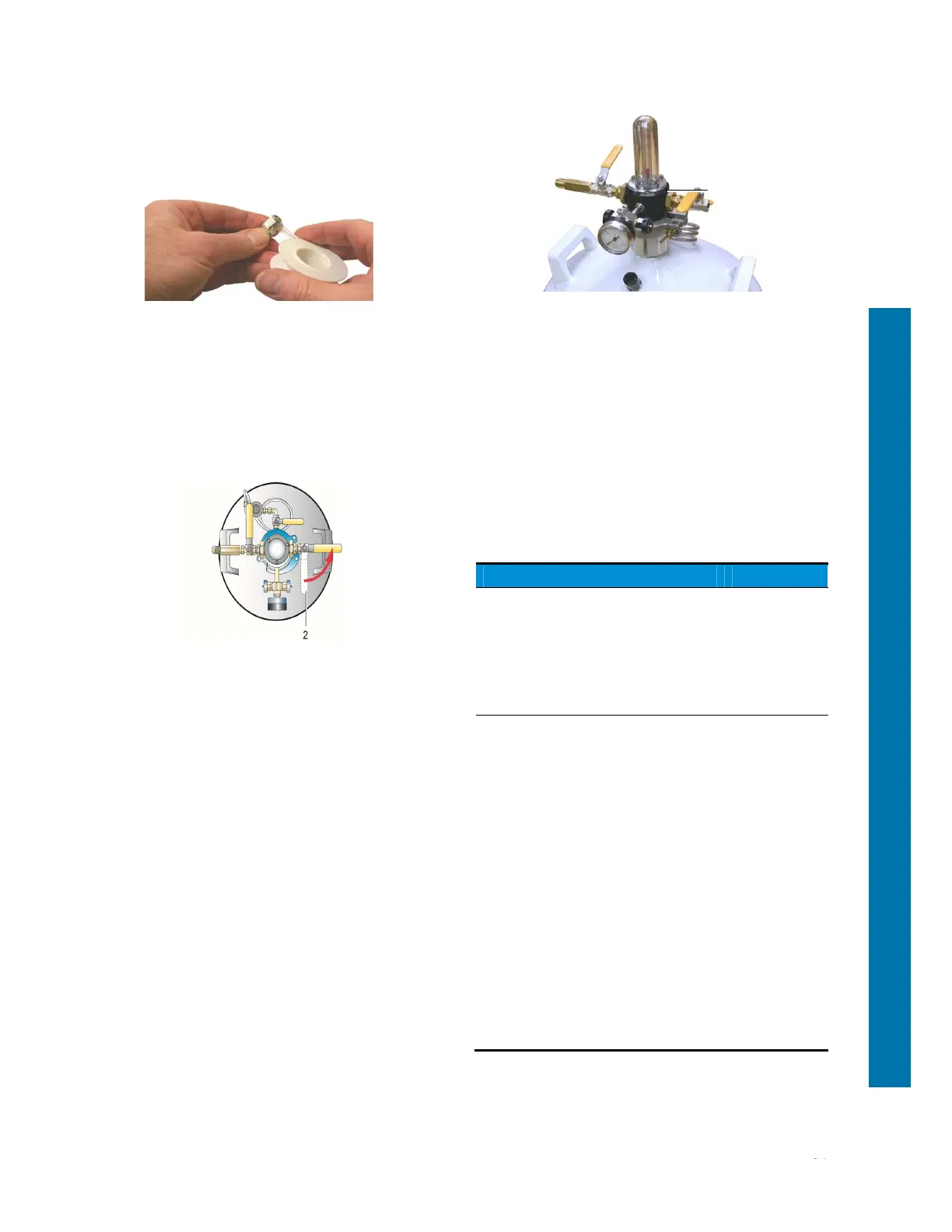

9.5.2 Changing valves

Proceed as follows:

1. Open the vent valve (1) to release any pressure.

2. Remove the control head (§ 7.2, page 21) and wait

for it to warm up.

3. Mount the swivelling screw fitting and the nitrogen

connector or the grooved end piece onto the new

valve.

4. Check the assembly for leaks as described in

section 9.3.4, on page 29.

5. Secure these connectors firmly to the valve so that

they do not become unscrewed when the flexible

transfer line is fitted and removed.

6. Screw the above premounted assembly onto the

control head.

7. Once the assembly is facing in the desired

direction, secure it in place by using the lock nut

(1) to lock it against the control head.

8. Test for leaks as described in section 9.3.4, on

page 29.

9.6 Interview frequency

This section is for skilled and qualified persons who

are authorized to carry out maintenance work.

Maintenance is necessary to ensure that the

equipment remains in normal operating condition. The

person who uses the equipment is responsible for

this. The tools used for maintenance operations must

be non-abrasive and should have no sharp edges or

points that could damage the surfaces.

Operation Frequency

Defrost the control head

Remove the ice that forms on the

control head with e.g. a hairdryer.

Be careful with the plastic parts

(stopper, fairing etc). The ice and/or

water must be recovered so that

they do not fall on the equipment.

Every 2

weeks

Cleaning the outside of the tank

Important note: cleaning is limited

to the outer parts of the device. The

use of acetone, solvents or any

other highly flammable chemicals

or liquid-containing chlorine

products is prohibited.

Wipe the plastic parts with a dry rag

and, if necessary, with a slightly

moist non-abrasive sponge (do not

use abrasive powder) or with

impregnated wipes.

Ordinary domestic cleaning

products (slightly abrasive creams

containing ammonia) applied with a

sponge will be acceptable for the

tank and the stainless steel parts.

Afterwards, rinse with a damp rag,

then wipe and leave to dry.

Every 5

weeks

(*)The frequencies shown are guideline intervals and should be adjusted by

the user according to the use made of the equipment.

1

Loading...

Loading...