2. Remove the control head. Refer to section 7.2, on

page 21.

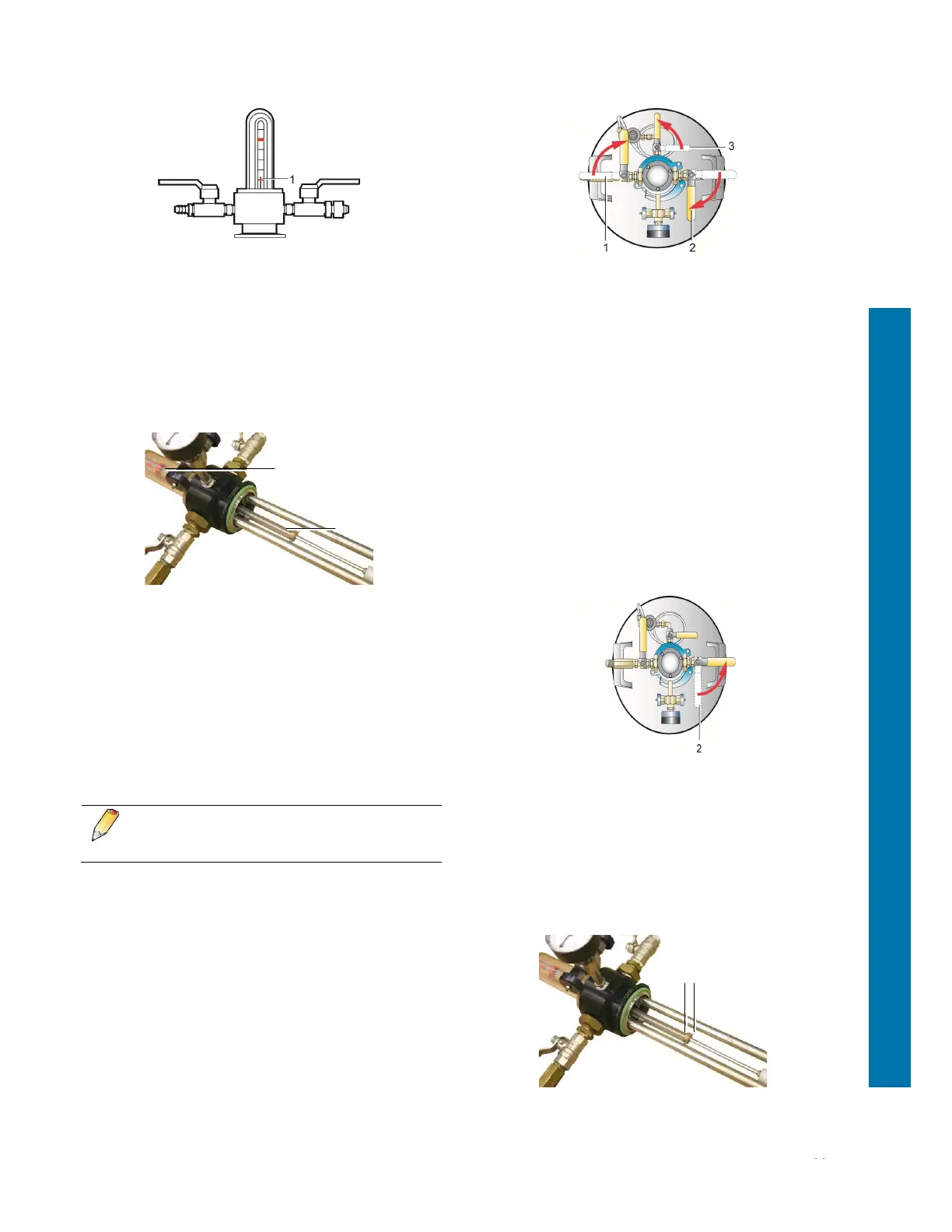

3. Once the assembly has warmed up to room

temperature, check that the stem (2) slides

smoothly along the indicator (1).

By grasping the float and sliding the stem between

the very bottom line and the very top line of the

indicator.

If it catches on anything, replace the assembly.

Adjusting the level indicator is covered in section

9.4, on page 29.

9.3.4 Inspecting for leaks

This must be checked every year. The required tools

are as follows:

A mixture of soap and water in a beaker.

A brush.

Proceed as follows:

The control head is mounted on a tank and

the tank is considered to be full of liquid

nitrogen.

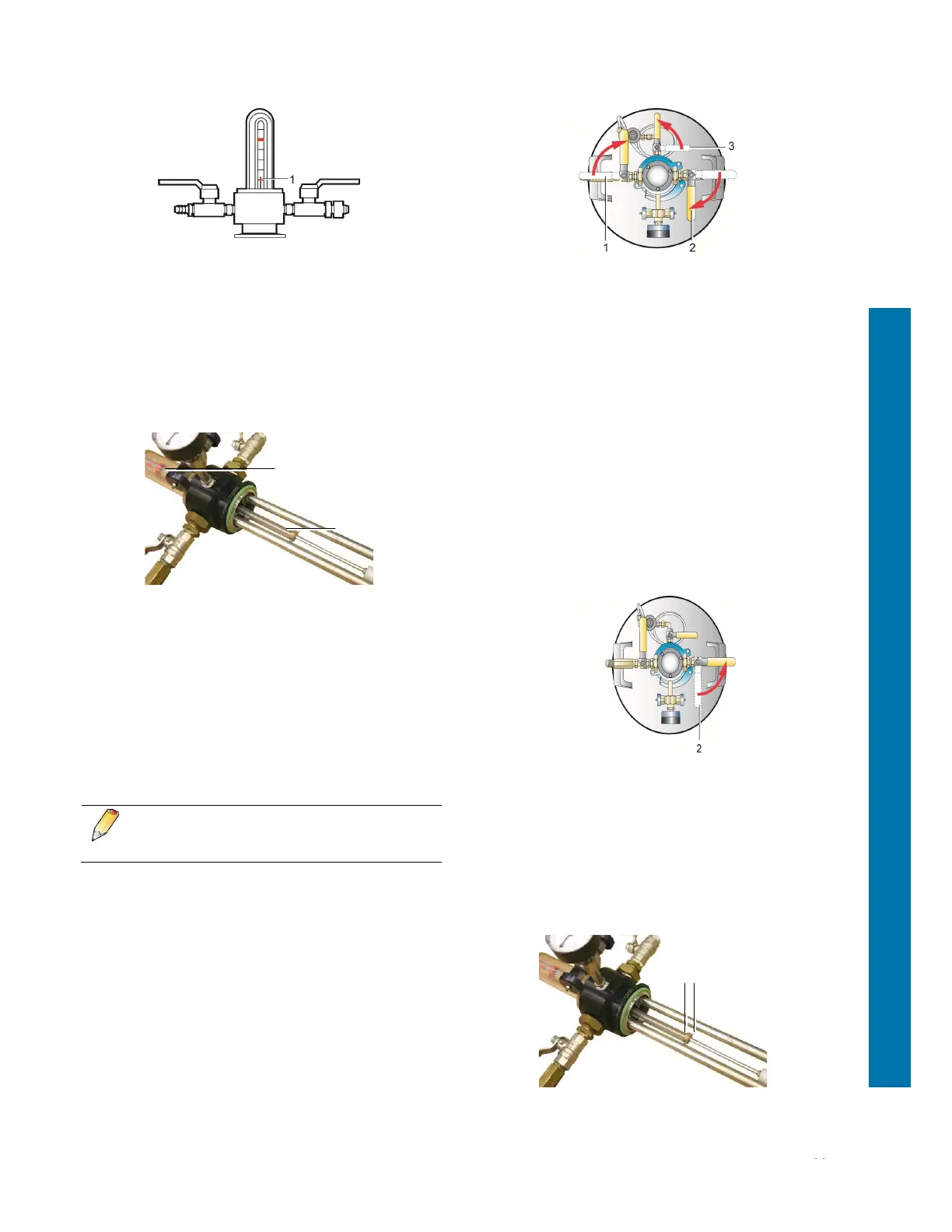

1. Check that the vent valve (2) and the

filling/withdrawal valve (1) are closed.

Open the pressure-building valve (3) and wait for

the tank's pressure to rise to 0.5 bars.

2. Using the brush, dab soapy water over the various

connections. If bubbles appear, this indicates a

leak. If a leak is observed, renew the seal on the

connection concerned.

9.4 Adjusting the level indicator

This becomes necessary after the equipment has

been roughly handled or following successive fitting

and removal of the control head.

9.4.1 Adjusting the zero mark

This procedure consists of making the red ring on the

stem coincide with the zero marker engraved on the

transparent cap. Proceed as follows:

1. Open the vent valve (1) to release any pressure.

2. Remove the control head (§ 7.2, page 21) and wait

for it to warm up.

3. Using a 2 mm hexagon key, unscrew the hex

socket grub screw (4) so that the ring (3) slides up

and down the stem.

2

1

3 4

Loading...

Loading...