Domestic Series 7000 Damped Driveshaft

70

2.3. Slide the back end of the driveshaft off of the

splined input shaft on the hydrostatic drive, and

remove the driveshaft.

NOTE: The original driveshaft is a two-piece

assembly. At the technician’s discretion, it may

be removed intact, or separated then removed.

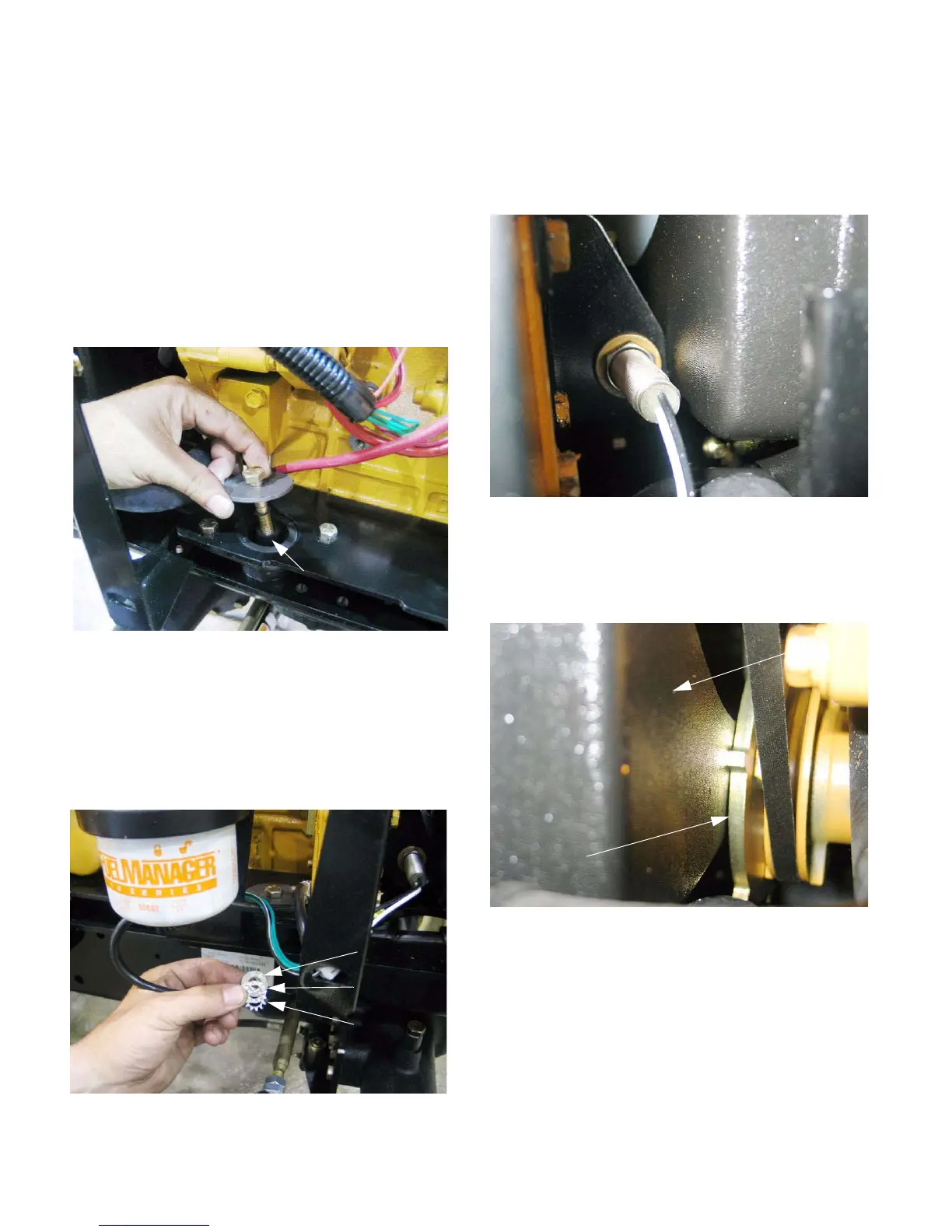

2.4. Remove the four bolts, nuts, and large flat wash-

ers that are used to secure the engine compres-

sion mounts to the tractor frame. This can be

done using a pair of 9/16” wrenches.

See Figure 2.4.

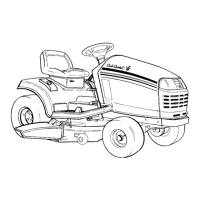

2.5. Of the four bolts, the one at the right front corner

of the engine also holds the negative battery

cable. The cable will come off when the nut is

removed, and there is a star-type lock-washer

between the cable eyelet and the frame to

ensure good electrical contact. See Figure 2.5.

2.6. Slide the engine as far forward as possible. The

left side of the engine goes slightly farther than

the right side because of interference between

the engine speed sensor and the fan shroud on

the right side. See Figure 2.6.

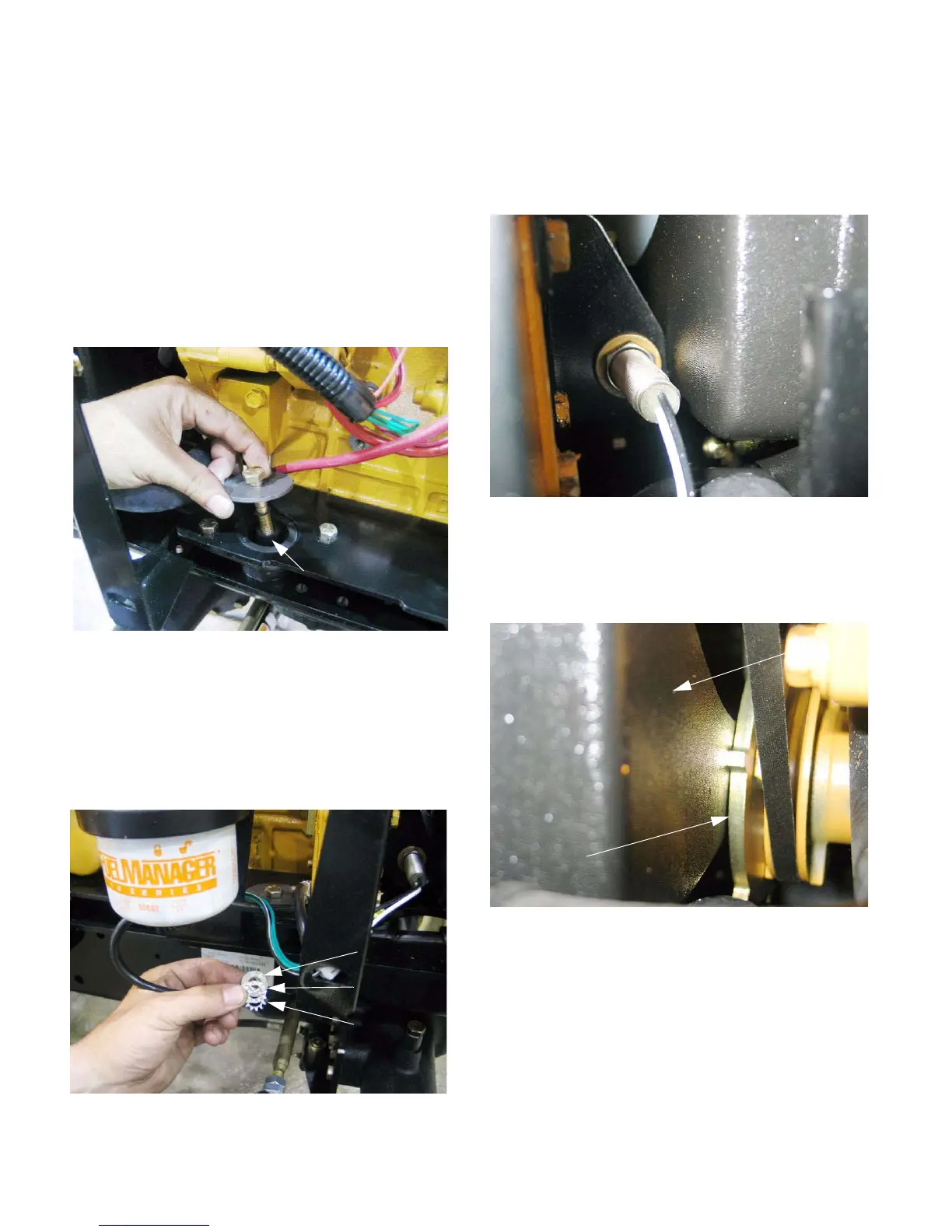

2.7. On the left side, the engine can be pushed for-

ward until the engine RPM plate (tone ring)

nearly touches the fan shroud. See Figure 2.7.

2.8. Apply a small amount of anti-seize compound to

the splined input shaft on the hydrostatic drive.

2.9. Apply a small amount of threadlocking com-

pound such as Loctite 242 (blue) to the clean

threads of the three bolts that hold the flange on

the front to the replacement driveshaft to the fly-

wheel.

Figure 2.4

Compression

mount

Figure 2.5

Nut

Cable eyelet

Star washer

Figure 2.6

Figure 2.7

RPM plate

Fan

shroud

Loading...

Loading...