Domestic Series 7000 Damped Driveshaft

71

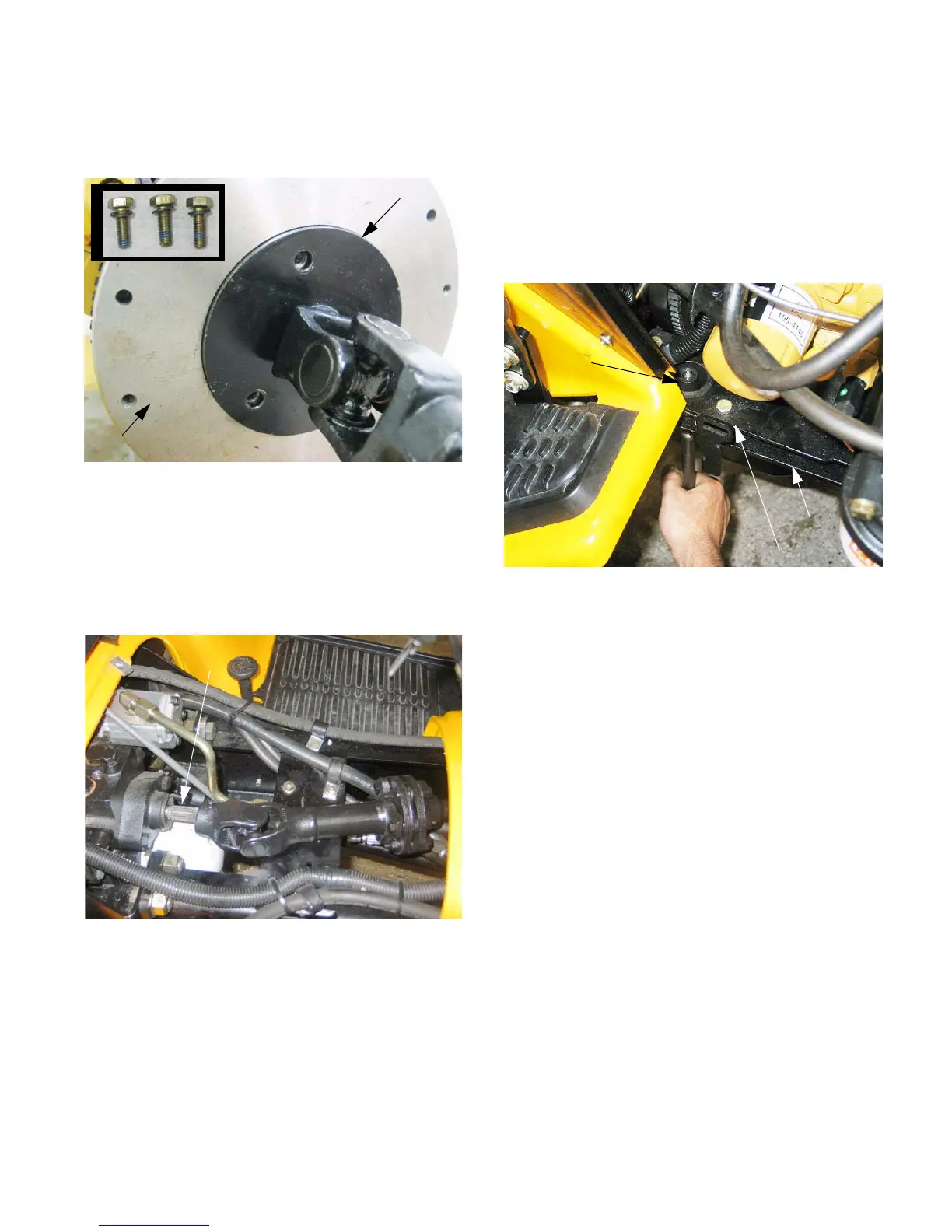

2.10. Slide the replacement driveshaft into position.

the flange should nest into the recess in the fly-

wheel.

2.11. Fasten the driveshaft to the flywheel using the

three loctited bolts with hardened washers.

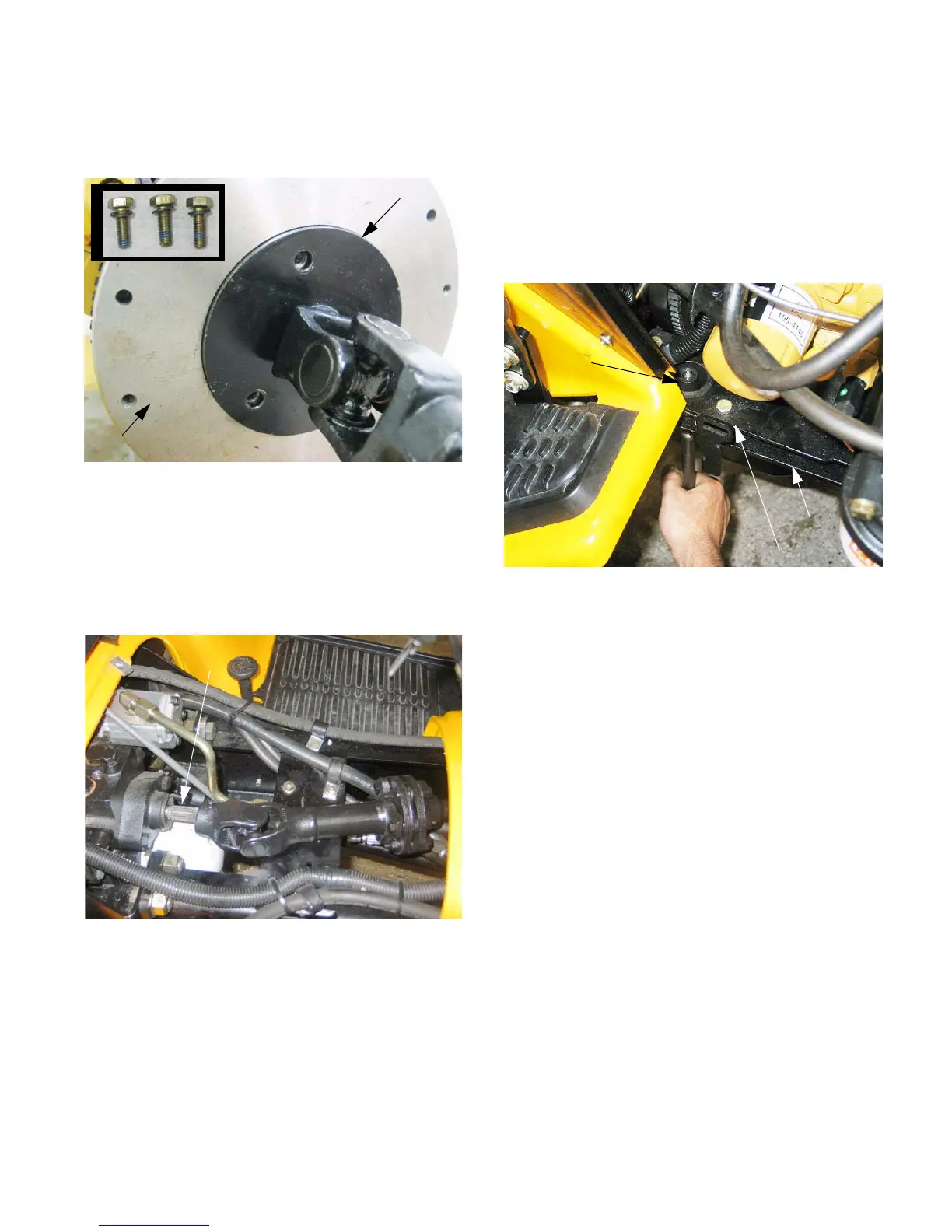

2.12. Slip the back end of the driveshaft onto the

splined input shaft on the hydrostatic drive.

See Figure 2.12.

2.13. Slide the engine back into position, so that the

mounting holes in the frame align with the holes

in the engine compression mounts.

NOTE: This will bring the rear yoke on the drive-

shaft into full engagement on the splines of the

hydrostatic drive.

Figure 2.10

Flywheel

Drive flange

Inset: bolts and

hardened washers

Figure 2.12

Splined input

shaft

2.14. Prevent the flywheel from turning using a fly-

wheel tool or by blocking the driveshaft, and

tighten the flange-to-flywheel bolts to a torque of

27-33 ft.-lbs (37-45 Nm).

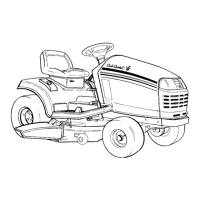

2.15. Make the final alignment of the engine so that

the engine mount bolts can be installed. A

tapered alignment pin is extremely useful for

this. See Figure 2.15.

2.16. Secure the engine compression mounts to the

frame using the nuts, bolts, and large flat wash-

ers previously removed. Tighten the nuts to a

torque of 23-31 ft.-lbs (31-40 Nm).

NOTE: If the locking feature on the nuts has

worn and they turn easily, replace them with new

ones, or apply a small amount of threadlocking

compound such as loctite 242 (blue) to the

threads.

NOTE: Do not forget the ground cable and star-

type lock washer on the right front mounting bolt.

2.17. Install the new fender cover that provides addi-

tional clearance for the flexible coupling on the

new driveshaft.

2.18. Connect the negative battery cable to the bat-

tery.

2.19. Install the over-flow bottle and hose.

2.20. Install the engine compartment side covers.

2.21. Close the hood.

2.22. Run and test the tractor in a safe area before

returning it to service.

Figure 2.15

Frame

Engine bracket

Compression

mount

Loading...

Loading...