12

CONDUIT CENTERLINE BENDING RADII

ASSEMBLY & OPERATING INSTRUCTIONS – 254 CONDUIT BENDER

(CONTINUED)

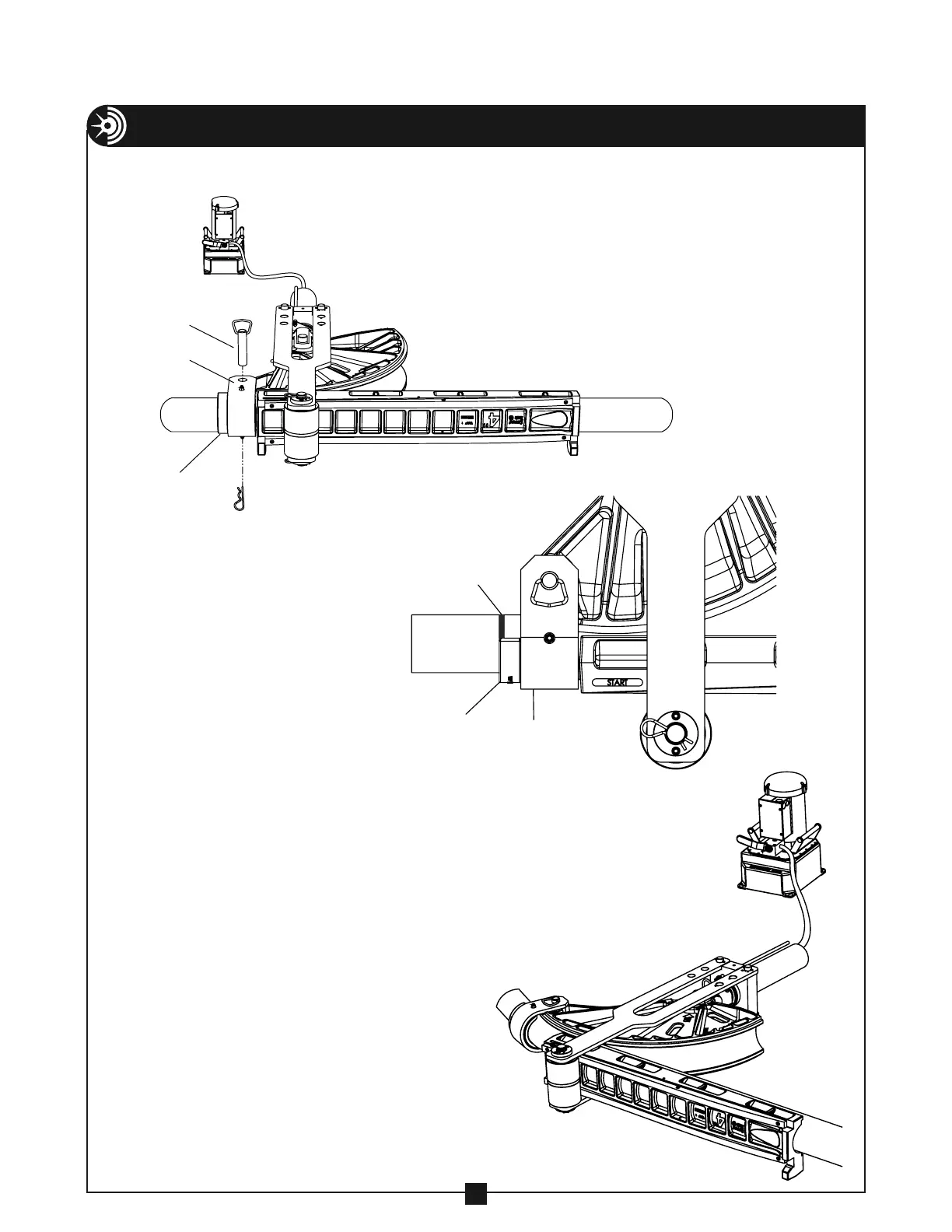

13. Place the correct size saddle around

the conduit as shown and rotate the

shoe as needed so that the saddle

hole and the shoe hole align. Insert

the saddle pin and secure with the

spring clip as shown in Figure 12.

NOTE: The saddle insert lip that

extends out should face away from

the follow bar (See figure 12A).

SADDLE

SADDLE INSERT LIP

SADDLE

BENDING MARK

P

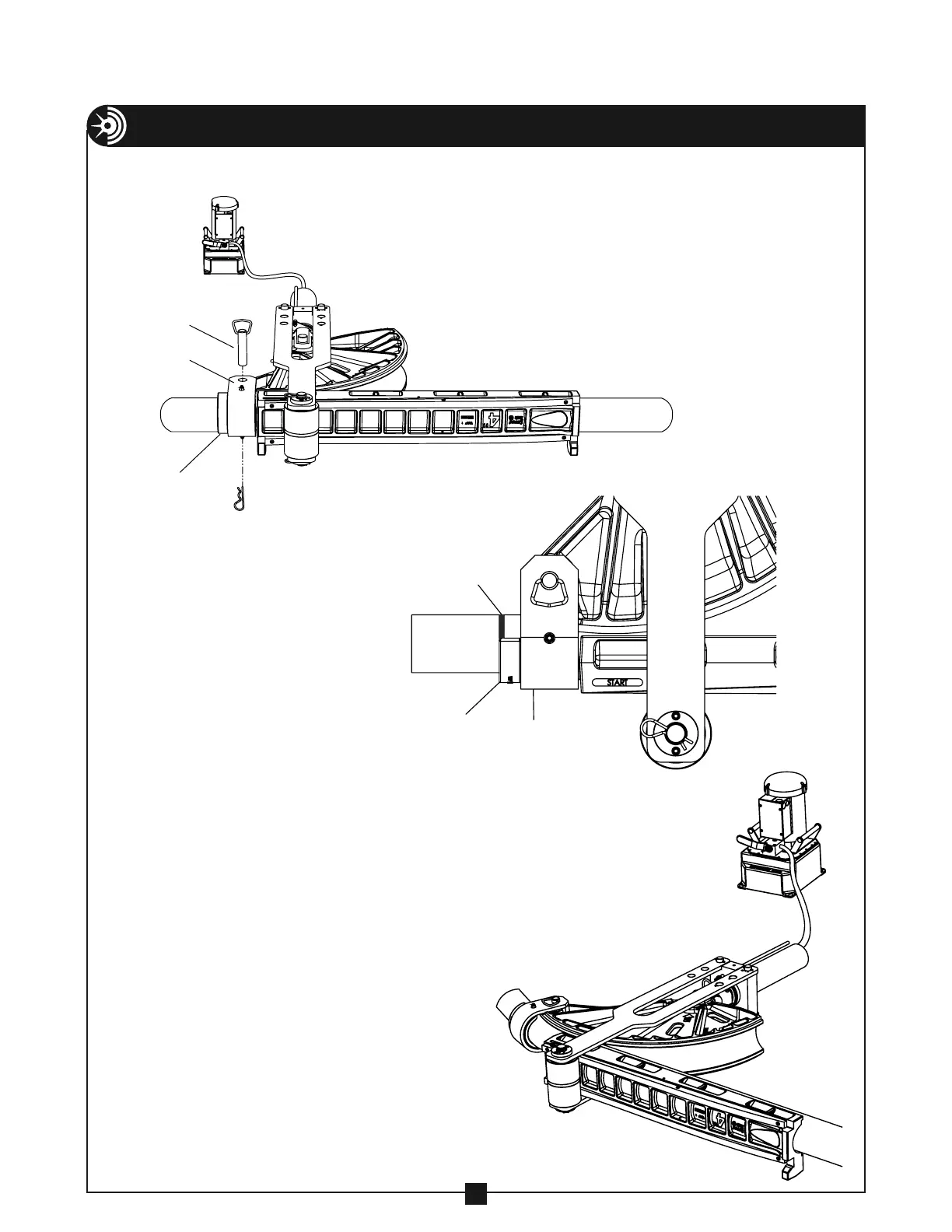

14. Make sure the saddle is flush with the front

of the follow bar. The bending mark on the

conduit should be aligned with the front

edge of the saddle insert lip (see figure 12A).

Rotate the pump valve lever to the closed

position and activate the hydraulic pump

until the shoe contacts the conduit and the

saddle and follow bar are snug.

15. DO NOT BEGIN BEND. Before bending — To

determine the amount of cylinder travel for

the size, type and degree of bend, refer to

the cylinder travel and bender calibration

information on page 16.

16. Activate the hydraulic pump to begin the

bend. (See figure 12B).

NOTE: DO NOT over extend the hydraulic

cylinder during operation. This will allow

hydraulic fluid to escape the cylinder and

may cause a hazardous condition.

FIGURE 12A

FIGURE 12B

FIGURE 12

Loading...

Loading...