MOTOR

Page G-2

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

To aid disassembly, heat only the commutator end cover

before attempting removal of the armature.

Once heated, place the commutator end cover/armature

assembly in press, giving as much support to the end

cover as possible, and press the armature out of the

bearing.

Push back each brush until its spring (15) is resting

against the side of the brush. This keeps the brushes out

of the way during bearing replacement (Ref Fig. 5 on

page G-3).

Remove internal snap ring (6) and heat the commutator

end cover again. Press bearing (7) out from commutator

end cover (3).

When installing bearing into end cover,

apply pressure against the bearing’s

outer race to avoid bearing damage.

Press the new bearing into the commutator end cover

using heat again to aid installation.

Install the snap ring.

If brushes are to be replaced, proceed now to

‘Brush Replacement’ before installing the

armature.

For proper location, the armature has a positive stop feature.

When installing armature into the bear-

ing/end cover assembly, support the

bearing’s inner race to avoid damage.

Press the armature into the new bearing using moderate

heat to aid installation.

Release brushes against commutator. Ensure the

springs are seated against the rear of the brushes and

are able to move freely.

Brush Replacement

Tool List Qty. Required

Wrench, 1/2"................................................................1

Ratchet, 1/4" drive .......................................................1

Socket, 5/16", 1/4" drive ..............................................1

Brushes should be measured as shown and replaced

when the minimum dimension of .62" (16 mm) is reached

(Ref Fig. 4 on page G-3).

Remove brush terminal hardware (12) at A1 and A2 (Ref

Fig. 3 on page G-2).

Remove screws (13) securing brush plate (14). Remove

brushes, rigging and brush plate.

Pull back each brush until each of the springs (15) rest

against the side of its brush (Ref Fig. 5 on page G-3).

Remove brushes and replace with new brush replace-

ment kit. Locate springs against the side of each brush.

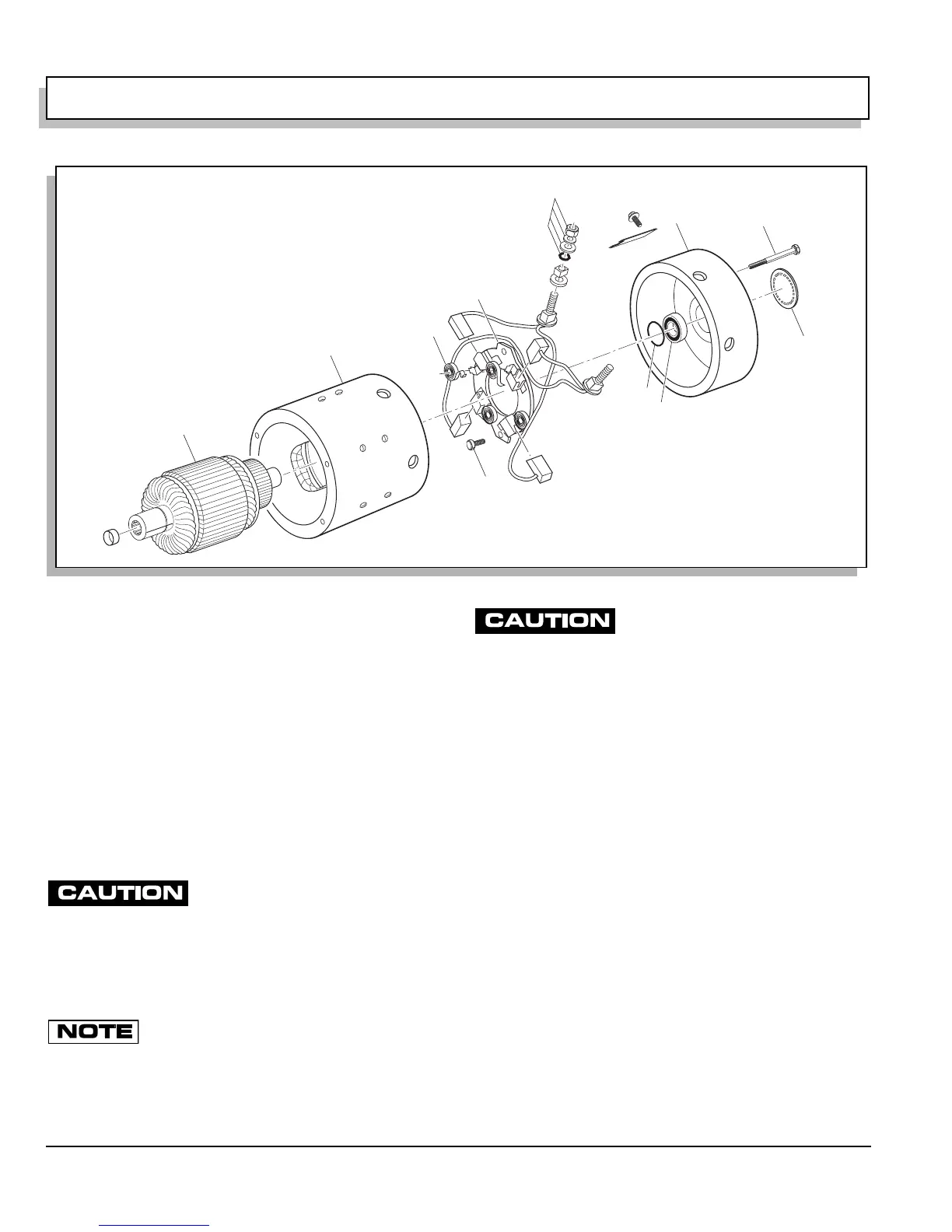

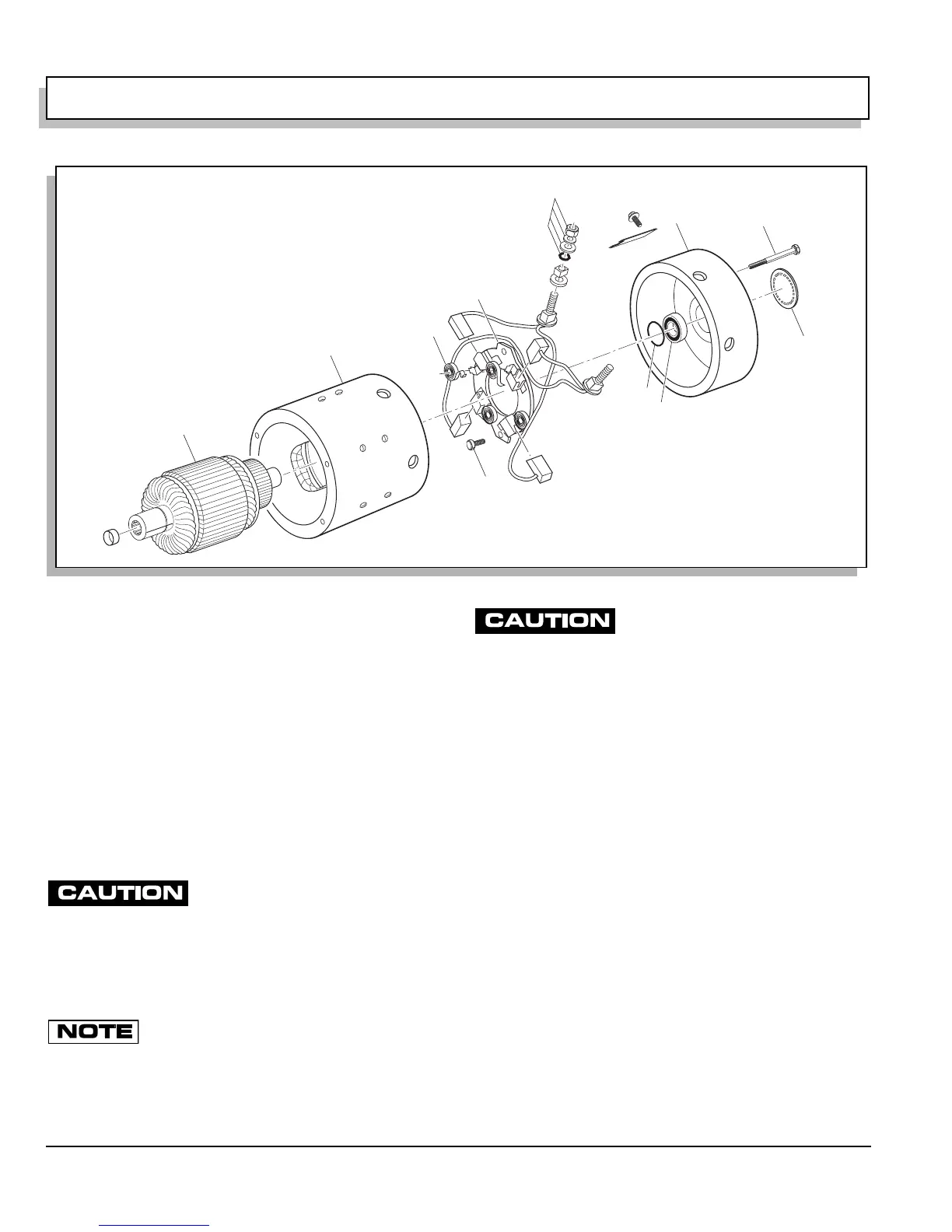

Fig. 3 Motor Components

A1

A2

1

2

3

4

5

6

7

12

13

14

15

Loading...

Loading...