K1000896E Operation and Maintenance Manual Inspection, Maintenance and Adjustment 4-51

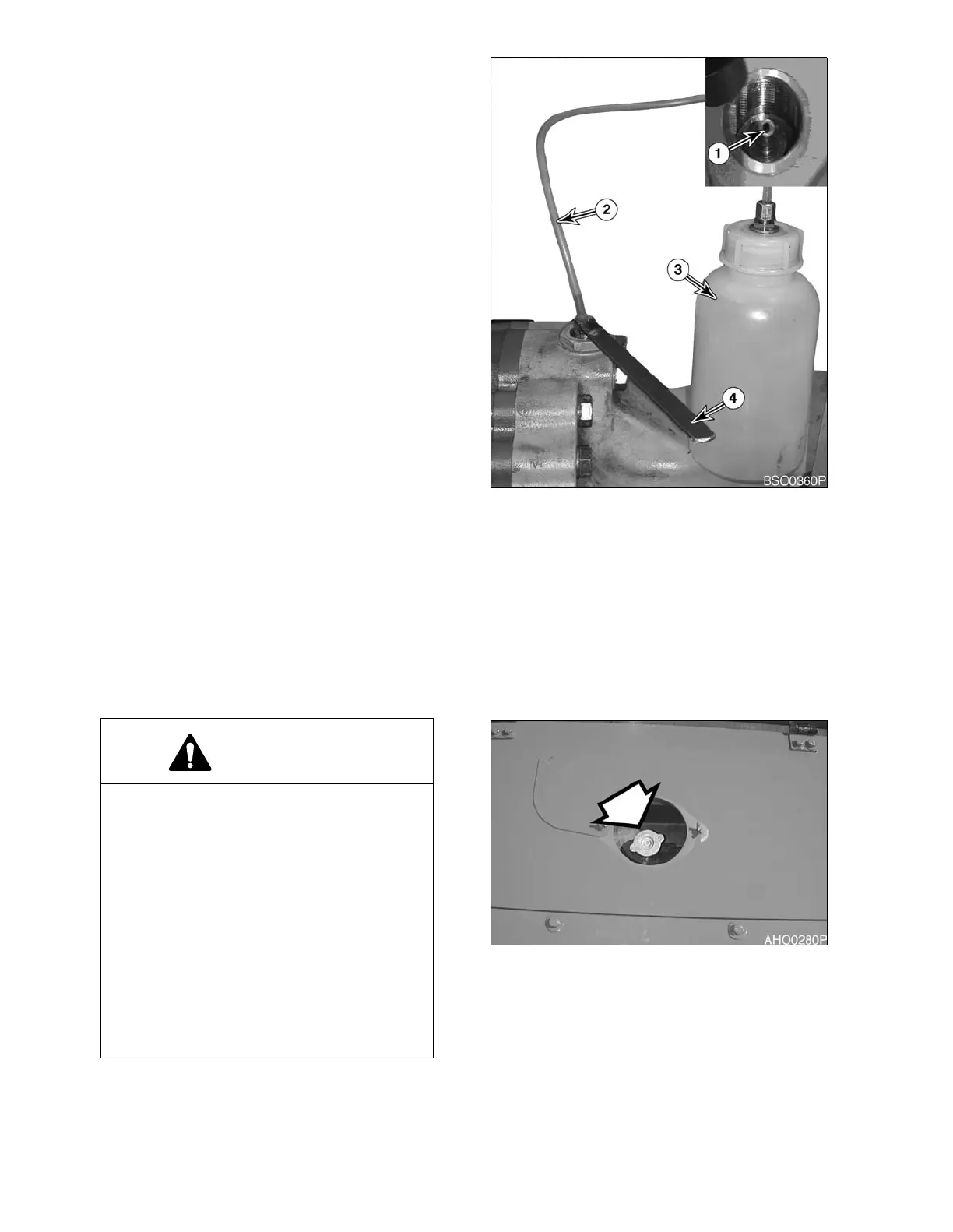

2. Remove plug (Figure 85) on axle. Increase

the height of bleeder (1, Figure 86) by

using special tool (4, Figure 86). Place one

end of a plastic hose (2, Figure 86) over

bleeder screw (1). Place other end of hose

in a container (3) filled with brake fluid.

NOTE: Dispose of drained fluids

according to local regulations.

3. Station one person in operator's cab, and

one person at bleeder screw on axle being

bled.

4. Open bleeder screw (1, Figure 86). Then

press down on brake pedal until it rests on

floor of cab. Hold pedal down on floor of

cab. Close bleeder screw while pedal is

being held down. After bleeder screw has

been closed, allow brake pedal to return to

upright position. Continue to open bleeder

screw and press down pedal as described

in this step, until fluid expelled from

bleeder hose has no air bubbles present.

5. Securely close bleeder screw (1, Figure

86). Install plug in axle.

6. Perform bleeding procedure on other three

locations.

CHANGE RADIATOR COOLANT

NOTE: Do not mix ethylene glycol and propylene glycol antifreeze together. If the two are mixed,

the protection level will be reduced to the level of the ethylene glycol. See “Engine Cooling

System” on page 4-60, for further details.

NOTE: This unit was factory filled with propylene glycol.

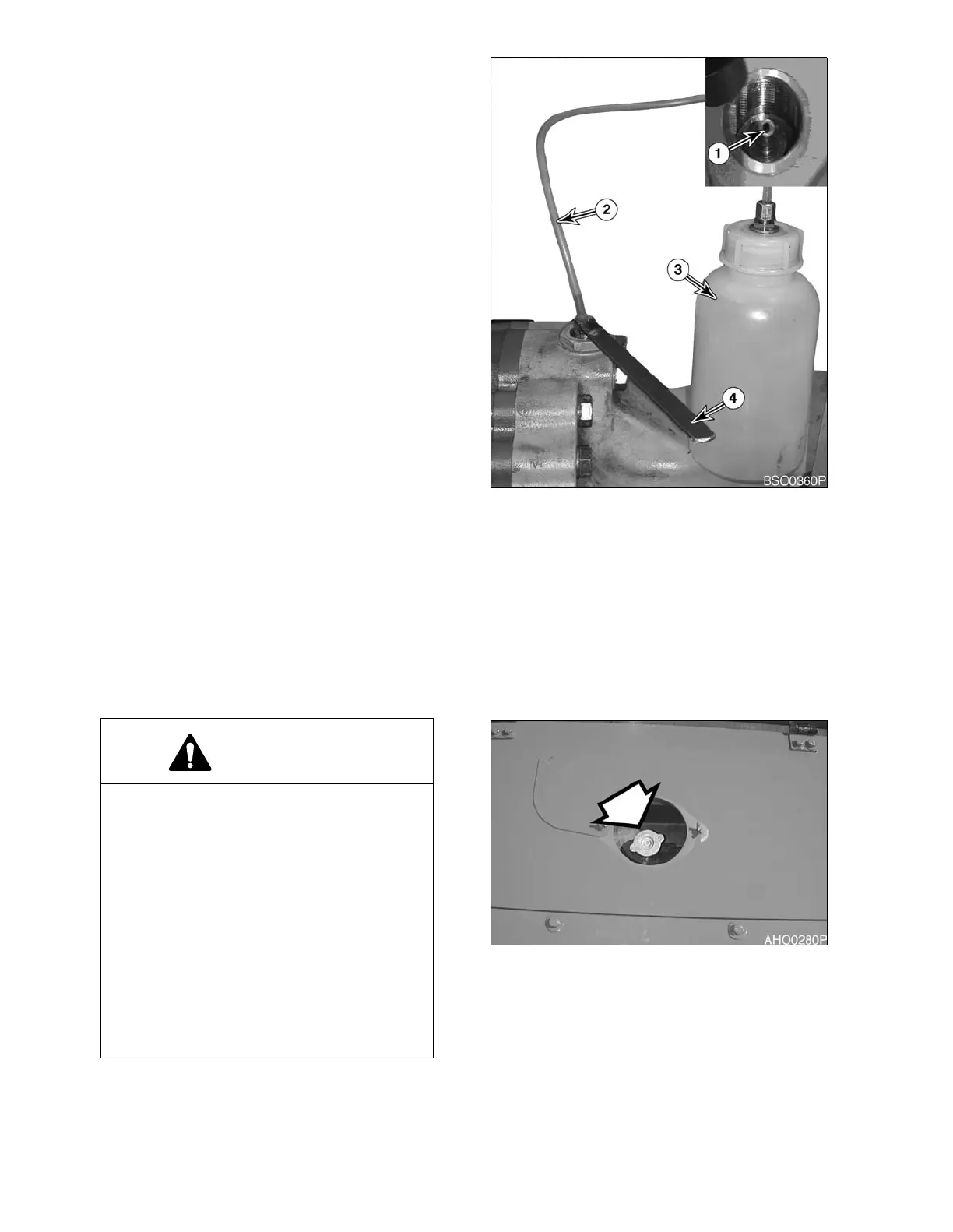

WARNING!

Allow the engine to cool before releasing

the radiator cap. Make sure to loosen the

cap slowly to release any remaining

pressure.

Radiator cleaning is performed while the

engine is running. Take extreme caution

when working on or near a running

engine. Make sure to lock out and tag the

controls notifying personnel that service

work is being performed.

Do not remove the radiator cap unless it is

required. Observe the coolant level in the

coolant recovery tank.

Figure 86

Figure 87

Loading...

Loading...