LRYEQ16A7Y1

CONVENI-PACK

4P448939-1A – 2016.07

Installation manual

12

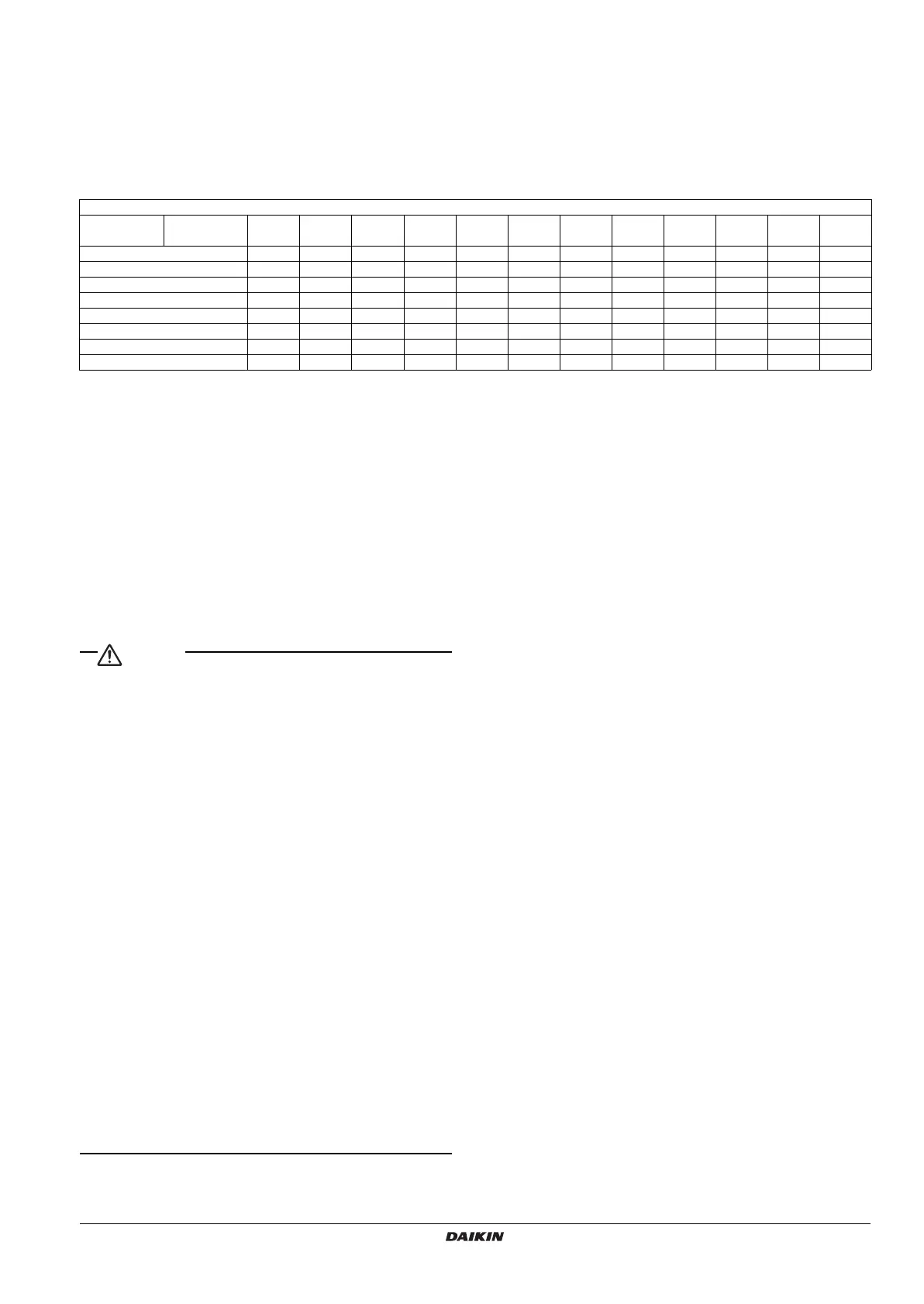

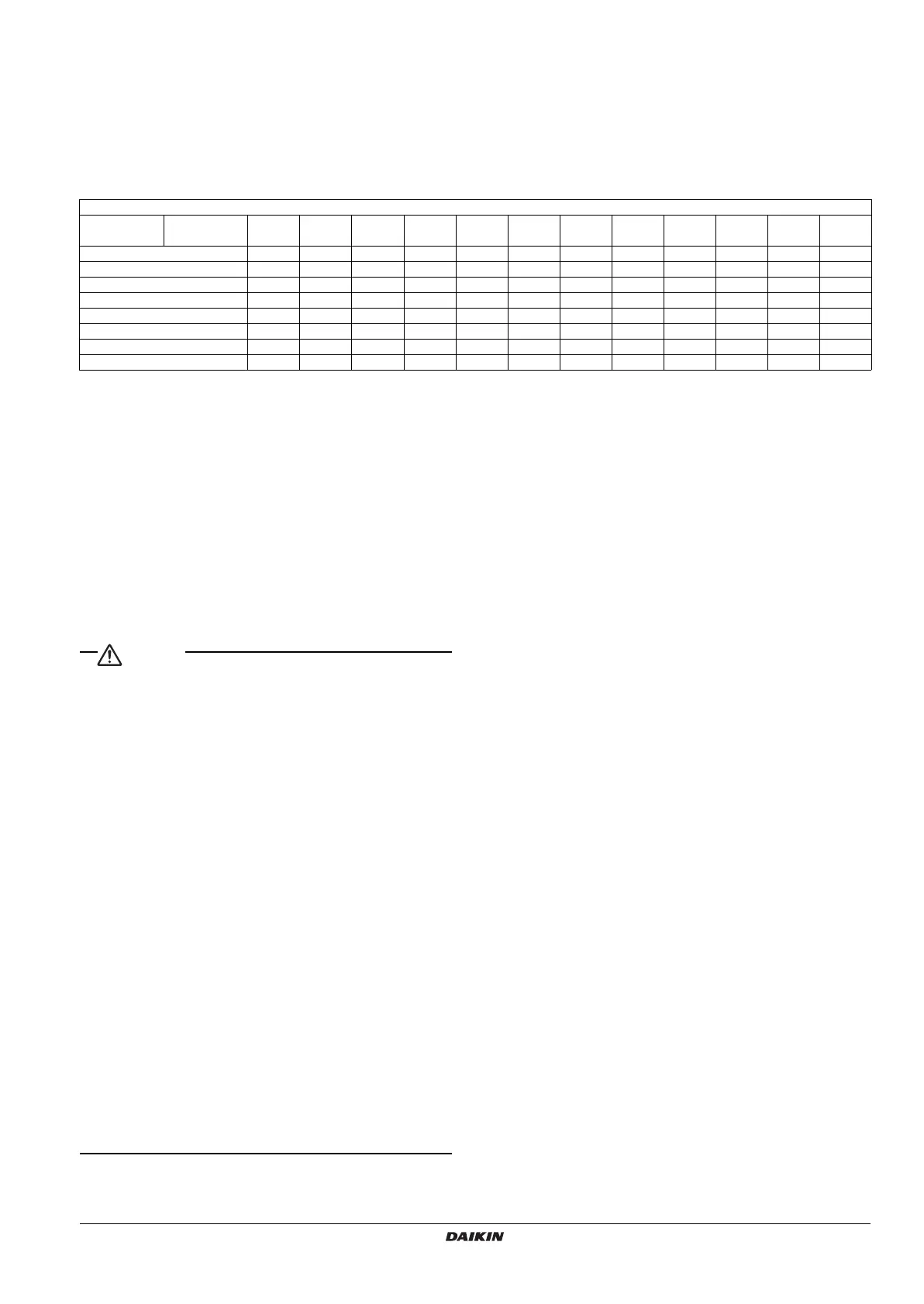

7. Expansion Valve Selection

This model has a larger degree of subcooling (subcooling ratio= condensing temperature - liquid refrigerant temperature at outdoor unit outlet) for

the liquid refrigerant of a refrigerator than that of refrigerators without a subcooling mechanism as it cools the liquid refrigerant with a plate type heat

exchanger.

When selecting an expansion valve for the load, select one based on the subcooling ratio for the liquid refrigerant in the following table.

• Calculated example: The subcooling ratio with evaporative temperature at –10°C and condensing temperature at 45°C is equal to 19K (liquid

refrigerant temperature at 26°C).

The liquid temperature in the booster unit is further decreased.

The liquid temperature of the refrigeration showcase inlet is approximately +10 degrees of the target evaporating temperature of the outdoor unit.

8. FIELD WIRING

To Electric Engineering Contractors

• Be sure to install an earth leakage breaker. The product incorpo-

rates inverter equipment. In order to prevent the malfunctioning of

the earth leakage breaker, make sure that the earth leakage

breaker withstands harmonic interference.

• Do not operate the CONVENI-PACK until refrigerant piping work is

completed, or otherwise the compressor will malfunction.

• Do not remove any electrical components such as thermistors or

sensors when connecting power supply wires or transmission

wires. The compressor may malfunction if the CONVENI-PACK is

operated with such electrical components removed.

• All field wiring and components must be installed by a licensed

electrician and must comply with relevant local and national regu-

lations.

• Be sure to use a dedicated power circuit. Never use a power supply

shared by another appliance.

• Never install a phase advancing capacitor. As this unit is equipped

with an inverter, installing a phase advancing capacitor will not only

deteriorate power factor improvement effect, but also may cause

capacitor abnormal heating accident due to high-frequency waves.

• Only proceed with wiring work after blocking off all power.

• Always ground wires in accordance with relevant local and national

regulations.

• This machine includes an inverter device. Connect earth and leave

charge to eliminate the impact on other devices by reducing noise

generated from the inverter device and to prevent leaked current

from being charged in the outer hull of the product.

• Do not connect the ground wire to gas pipes, sewage pipes, light-

ning rods, or telephone ground wires.

Gas pipes: can explode or catch fire if there is a gas leak.

Sewage pipes: no grounding effect is possible if hard plastic pip-

ing is used.

Telephone ground wires and lightning rods: dangerous when

struck by lightning due to abnormal rise in electrical potential in the

grounding.

• Be sure to install an earth leakage circuit breaker.

This unit uses an inverter, so install the earth leakage circuit

breaker that be capable of handling high harmonics in order to pre-

vent malfunctioning of the earth leakage circuit breaker itself.

• Earth leakage circuit breaker which are especially for protecting

ground-faults should be used in conjunction with main switch or

fuse for use with wiring.

• Electrical wiring must be done in accordance with the wiring dia-

grams and the description herein.

• Do not operate until refrigerant piping work is completed.

(If operated before complete the piping work, the compressor may

be broken down.)

• Never remove thermistor, sensor or etc. when connecting power

wiring and transmission wiring.

(If operated with thermistor, sensor or etc. removed, the compres-

sor may be broken down.)

• This product have reversed phase protection detector that only

works when the power is turned on. If there exists black out or the

power goes on and off which the product is operating, attach a

reversed phase protection circuit. Running the product in reversed

phase may break the compressor and other parts.

• Attach the power wire securely. Introducing power with a missing

N-phase or with a mistaken N-phase will break the unit.

• Never connect the power supply in reversed phase.

The unit can not operate normally in reversed phase.

If you connect in reversed phase, replace two of the three phases.

• Make sure the electrical unbalance ratio is no greater than 2%. If it

is larger than this, the unit’s lifespan will be reduced.

If the ratio exceeds 4%, the unit will shut down and an malfunction

code will be displayed on the indoor remote controller.

• Connect the wire securely using designated wire and fix it with

attached clamp without applying external pressure on the terminal

parts (terminal for power wiring, terminal for transmission wiring

and earth terminal).

• Install a switch that allows you to switch all poles from the main

power supply.

Subcooling ratio (K) (subcooling ratio = condensing temperature - liquid refrigerant temperature)

Condensing

temperature

Evaporative

temperature

-45°C -40°C -35°C -30°C -25°C -20°C -15°C -10°C -5°C -0°C 5°C 10°C

20°C 31K 28K 26K 23K 20K 18K 15K 13K 11K 9K 6K 4K

25°C 31K 29K 26K 24K 21K 19K 16K 14K 12K 10K 8K 6K

30°C 32K 29K 27 24K 22K 19K 17K 15K 13K 11K 9K 7K

35°C 32K 30K 27K 25K 23K 20K 18K 16K 14K 12K 10K 9K

40°C 32K 30K 28K 26K 23K 21K 19K 17K 16K 14K 13K 10K

45°C 33K 31K 29K 26K 24K 22K 21K 19K 17K 15K 14K 12K

50°C 34K 31K 29K 27K 25K 24K 22K 20K 18K 17K 15K 14K

55°C 34K 32K 30K 28K 27K 25K 23K 22K 20K 18K 17K 16K

4PEN448939-1A.book Page 12 Monday, September 5, 2016 7:12 PM

Loading...

Loading...