Installation manual

15

LRYEQ16A7Y1

CONVENI-PACK

4P448939-1A – 2016.07

Point for attention regarding quality of the public electric power

supply

This equipment complies with respectively:

EN/IEC61000-3-11

(1)

provided that the system impedance Z

sys

is

less than or equal to Z

max

and

EN/IEC61000-3-12

(2)

provided that the short-circuit power S

sc

is

greater than or equal to the minimum S

sc

value

at the interface point between the user’s supply and the public system.

It is the responsibility of the installer or user of the equipment to

ensure. by consultation with the distribution network operator if neces-

sary, that the equipment is connected only to a supply with respec-

tively:

Z

sys

less than or equal to Z

max

and

S

sc

greater than or equal to the minimum S

sc

value.

(1) European/International Technical Standard setting the limits for

voltage changes.

Voltage fluctuations and flicker in public low-voltage supply sys-

tems for equipment with rated current ≤ 75A

(2) European/International Technical Standard setting the limits for

harmonic currents produced by equipment connected to public

low-voltage systems with input current > 16A and ≤ 75A per

phase.

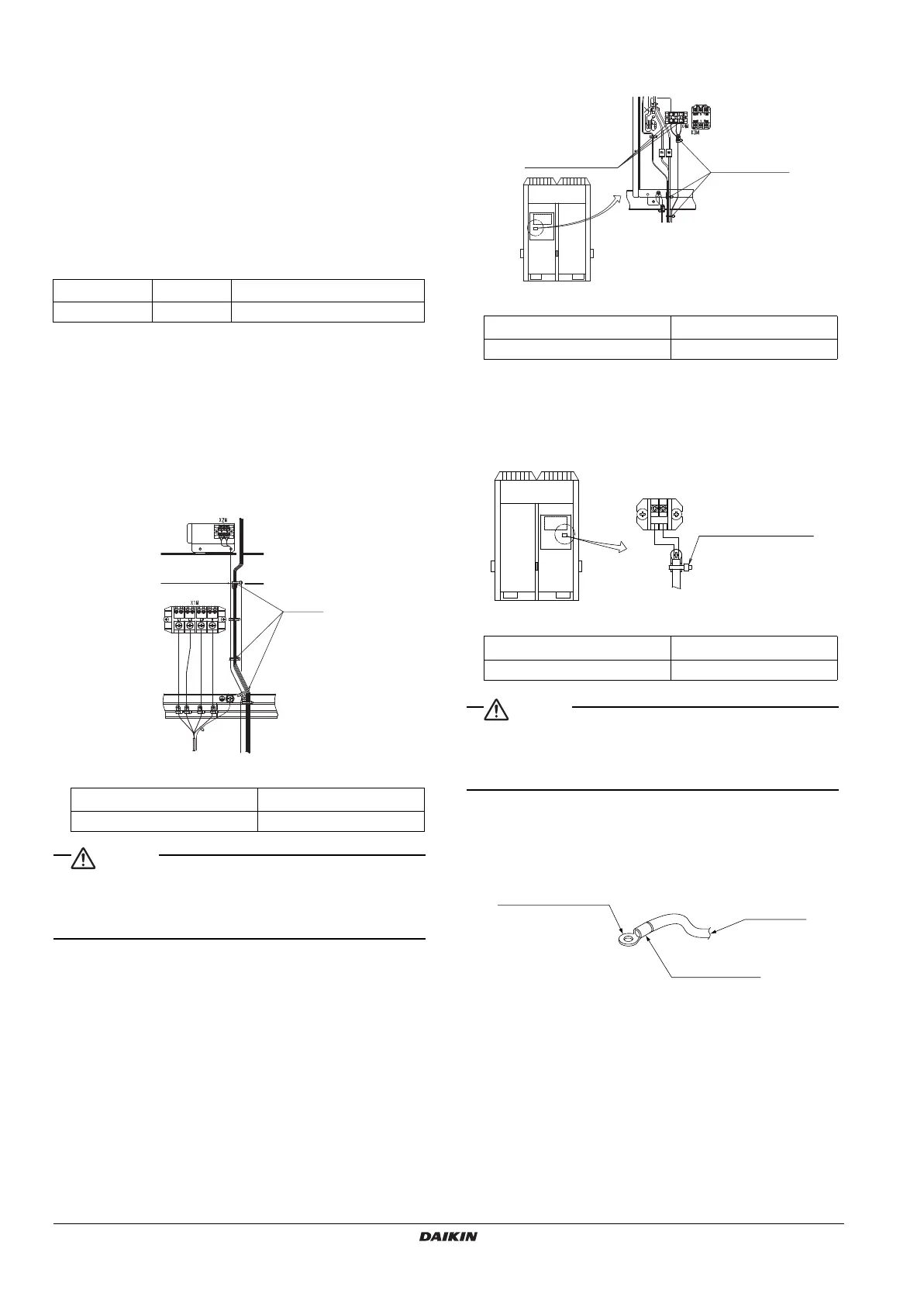

Operation output wiring connections

• Connect operation output wiring to the X2M terminal block and

clamp as indicated by the following diagram:

X2M wire specifications

• Refer to the "8-1 Example of Wiring Entire System" by all means

when connecting the operation output wiring.

A compressor failure may result if the operating output wiring is not

connected.

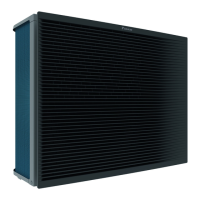

Warning, alarm wiring connections

• Connect warning, alarm wiring to the X4M terminal block and

clamp as indicated by the following diagram:

X4M wire specifications

Note: Be sure to insulate the mating equipment.

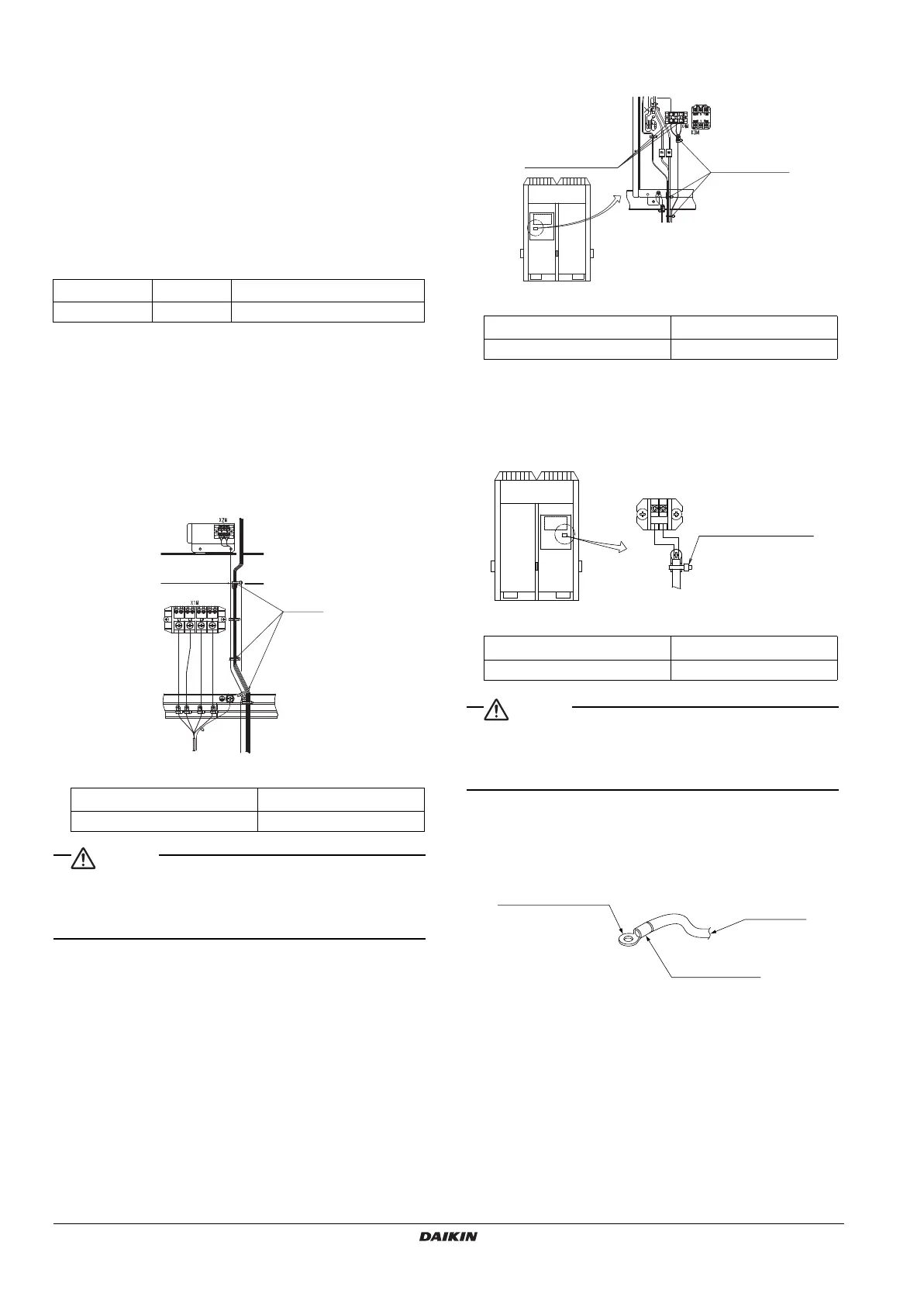

Remote operating switch wiring connections

• When installing a remote operating switch, clamp as indicated by

the following diagram:

X3M wire specifications

• For Remote switch, use non-voltage contact for microcurrent (not

more than 1mA, 12VDC)

• If the remote operating switch will be used to start and stop the unit,

set the operating switch to "REMOTE".

<Precautions for Terminal Connections>

• Be sure to use ring-type crimp-style terminals provided with insu-

lation sleeves.

• Use specified electric wires for the wiring and secure the wiring so

that external force will not be imposed on the terminal block.

• Use an appropriate screwdriver to tighten the terminal screws.

Small-sized screwdriver will damage the screw heads and cannot

tighten the screws properly.

• Do not tighten the terminal screws in excess, otherwise the screws

may be damaged.

• Refer to the following table for the tightening torque values of the

terminal screws.

• Take out the earth wire from the notch of the cup washer and lay

the wire carefully so that other wires will not be caught by the

washer. Otherwise, the earth wire may not contact sufficiently and

the earthing effect of the wire may be lost.

Z

max

(Ω)minimum S

sc

value

LRYEQ16A7Y1 0.24 1020KVA

Electric wire thickness

0.75~1.25 mm

2

Max. wiring length 130 m

Electric wire thickness

0.75~1.25 mm

2

Max. wiring length 130 m

Electric wire thickness

0.75~1.25 mm

2

Max. wiring length 130 m

Fix the wiring

X3M

2

1

Secure remote

operating switch

wiring to the resin

block using a clamp

(field supply).

Crimp-style terminal

Insulating sleeve

Power wire

4PEN448939-1A.book Page 15 Monday, September 5, 2016 7:12 PM

Loading...

Loading...