Condenser Fan Operation for Variable Speed Compressor Low Ambient Option

(MPS 040 and 050 Only)

Daikin’s head pressure control operates by modulating the

motor speed of one condenser fan on the VFD compressor

refrigeration circuit in response to the condenser pressure.

VFD compressor refrigerant circuit contains a solenoid valve

that blocks refrigerant ow to half of the condenser coil, which

effectively removes 50% of the condenser surface from the

circuit for low load/low ambient conditions.

This option allows for mechanical cooling operation down to 0F

(-18C). The VFD option senses refrigerant head pressure and

varies the fan speed accordingly. When the pressure rises, the

SpeedTrol increases the speed of the fan, when the pressure

falls. SpeedTrol decreases the speed of the fan.

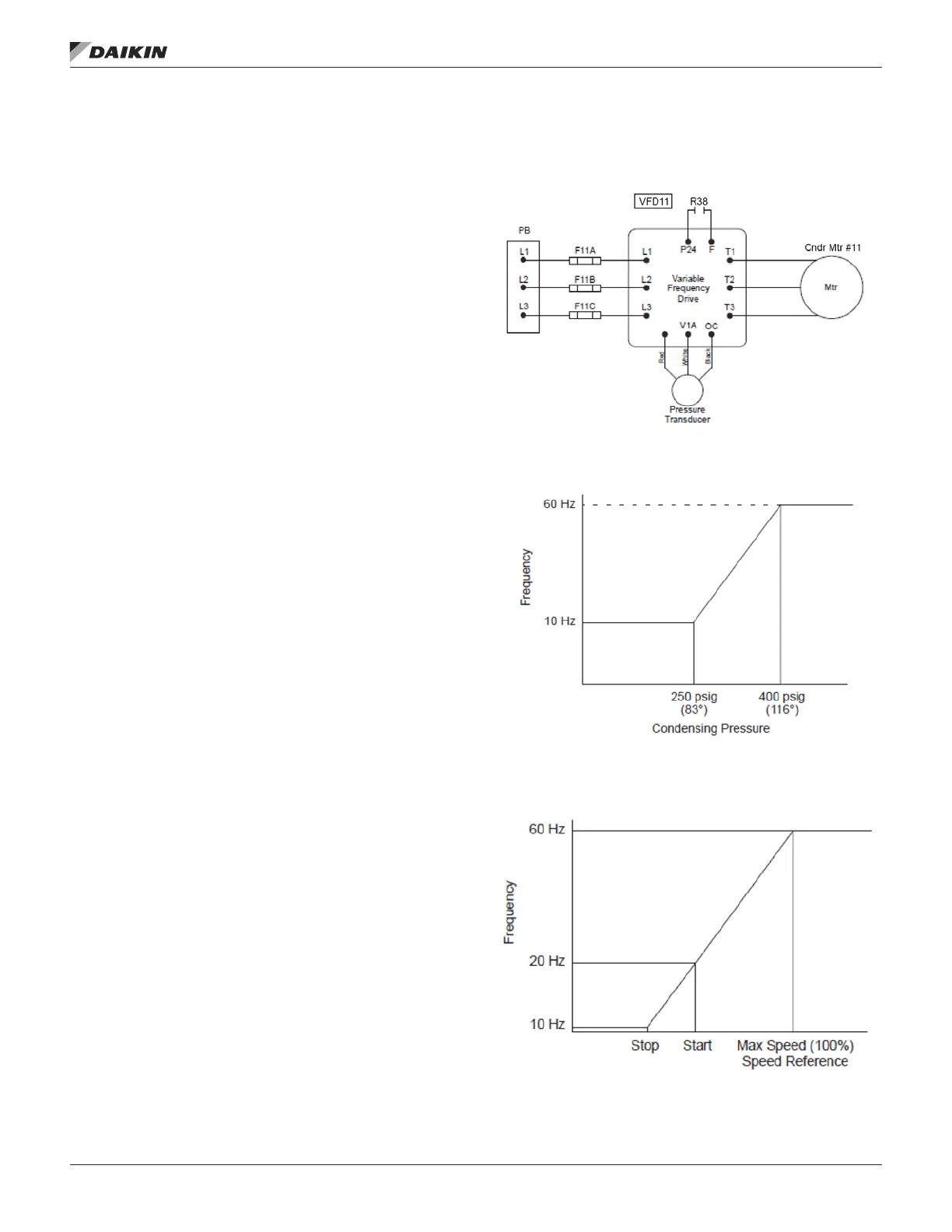

The VFD throttling range is 250 to 400 psig, xed, with a

corresponding fan speed range of 10Hz to 60Hz. The fan

motor is a three-phase motor, identical to the unit voltage

(208V to 575V) and is controlled by a variable frequency

drive. The variable frequency drive receives a signal from a

pressure transducer and varies the speed of the condenser fan

accordingly.

The SpeedTrol arrangement for VFD compressors is also

employing “Start-Stop control by Speed reference Level” in

which the VFD will stop the condenser fan motor under certain

conditions. If the head pressure were to fall below 250 PSIG

with the condenser fan operating at minimum speed of 10Hz

(possibly due to a low ambient or high wind condition) the

VFD will shut down the condenser fan. The VFD will restart

the condenser fan at 20 Hz if head pressure rises to a level

above 250 PSIG. In addition to modulating fan speed, a

refrigerant solenoid valve is included in circuit #1. Operation of

the solenoid valve is based on head pressure. If the average

condensing pressure falls below 250 PSIG (83F sat) for 60

seconds, the condenser solenoid valve closes, effectively

removing 50% of the condensing surface. If the averaging

condensing pressure rises above 350 PSIG (105F sat) for 60

seconds, the condenser solenoid valve is opened, activating

the entire condenser surface. The solenoid valve is disabled

above an outdoor ambient of 80F. The solenoid valve is in a

normally open conguration.

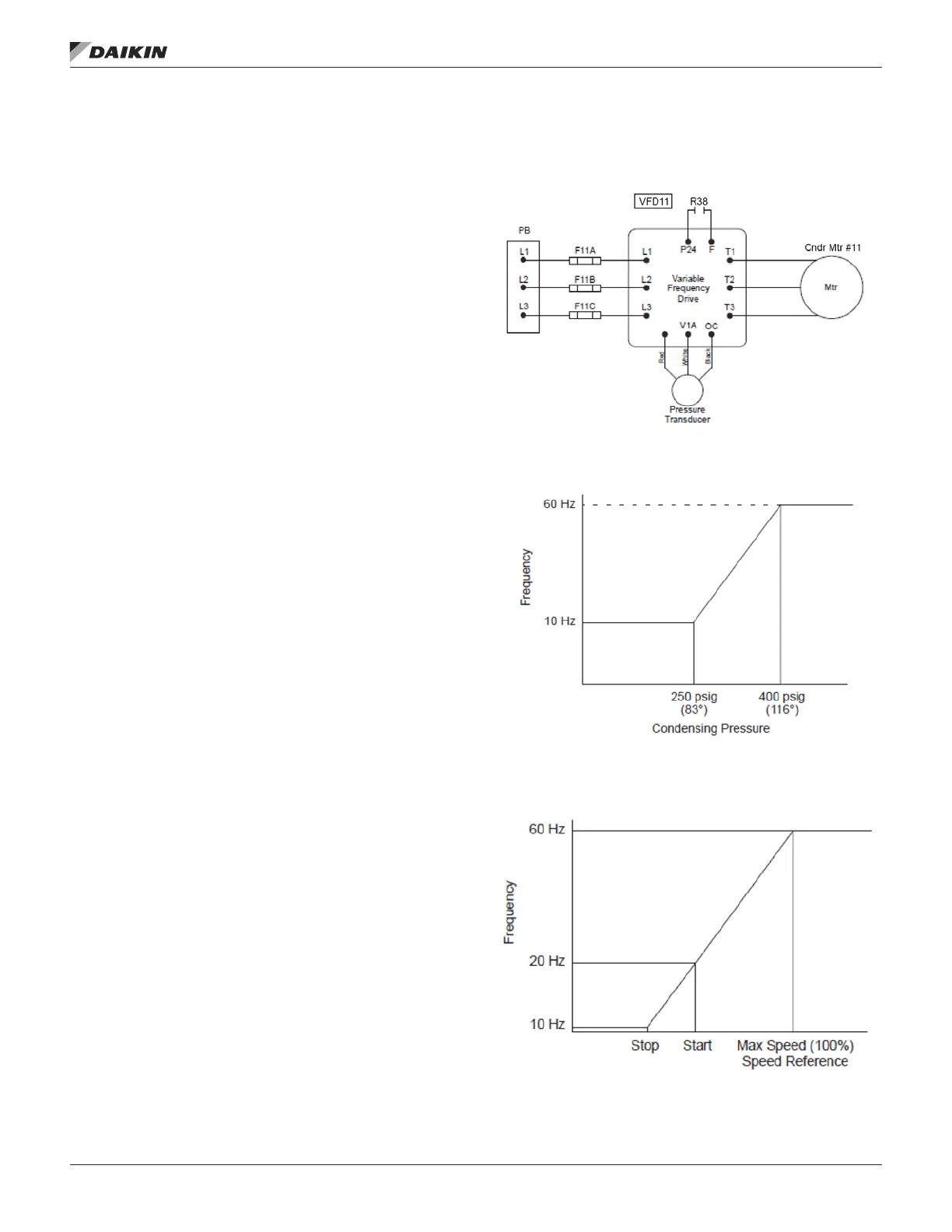

Refer to Figure 19 for wiring schematics of SpeedTrol.

Refer to Figure 20 and Figure 21 for SpeedTrol operating

characteristics.

Figure 19: R-410A Speedtrol

Figure 20: Speedtrol Operating Characteristics (for

Variable Speed Inverter Compressor Units)

Figure 21: Speedtrol Operating Characteristics (for

Variable Speed Inverter Compressor Units with Start-Stop

Control)

OM 920-6 • MICROTECH UNIT CONTROLLER 122 www.DaikinApplied.com

operaTor’s guIde

Loading...

Loading...