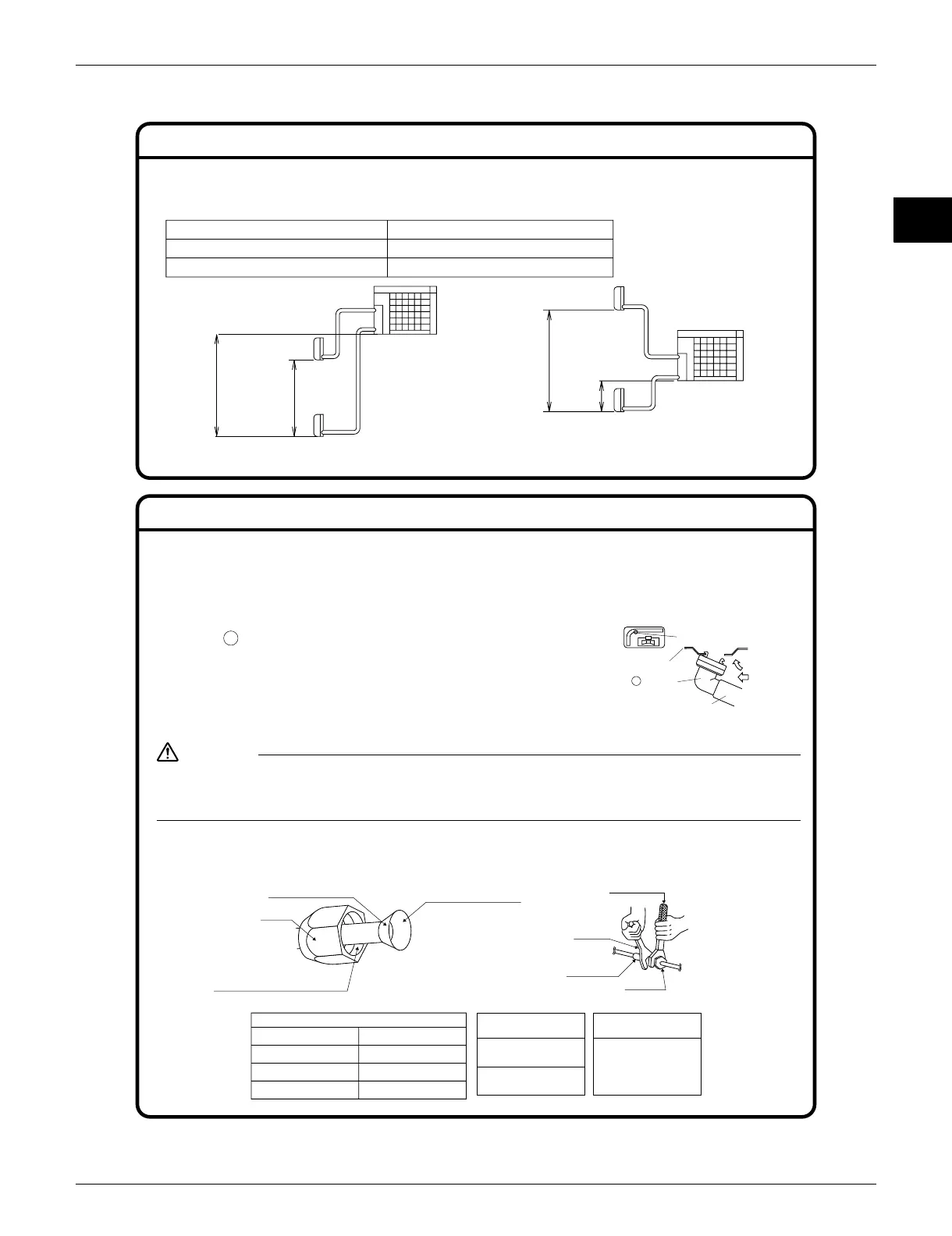

Selecting a Location for Installation of the Indoor Units

Outdoor Unit

Level

difference: 24.6 ft

max.

Level

difference:

49.2 ft max.

Indoor Unit

Outdoor Unit

Drain-water hole

Bottom frame

B Drain plug

While pressing

Hose (available commercially,

inner dia. 5/8 in)

Flare nut tightening torque

Flare nut for φ1/4 10.5~12.7 ft-lbf

Flare nut for φ3/8 24.1~29.4 ft-lbf

Flare nut for φ1/2 36.5~44.5 ft-lbf

Flare nut for φ5/8 45.6~55.6 ft-lbf

Level

difference:

49.2 ft max.

Indoor Unit

Outdoor Unit

Level

difference:

24.6 ft max.

● The maximum allowable length of refrigerant piping, and the maximum allowable height difference between the

outdoor and indoor units, are listed below. (The shorter the refrigerant piping, the better the performance. Connect so

that the piping is as short as possible. Shortest allowable length per room is 9.8 ft.)

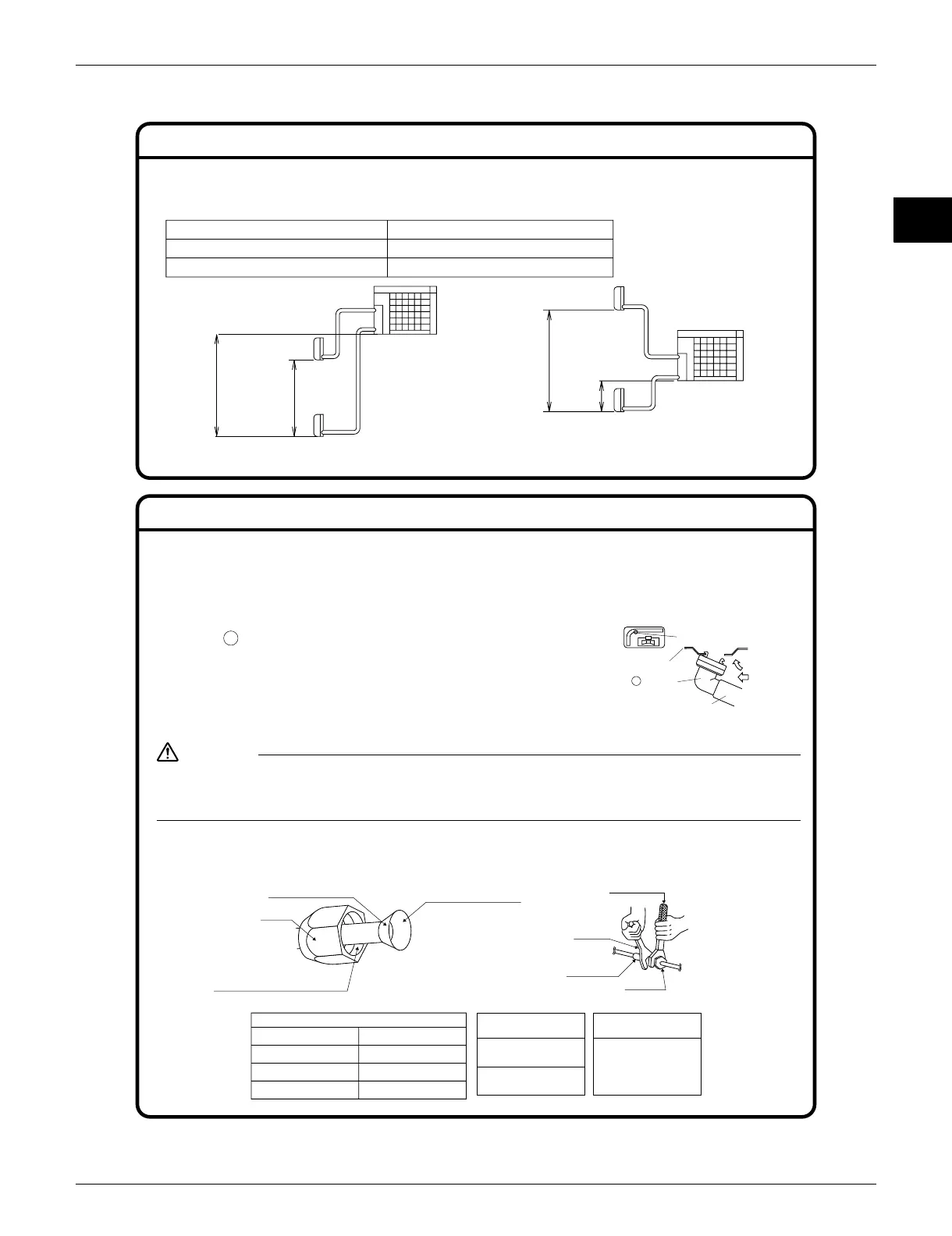

1. Installing Outdoor Unit

1)

When installing the outdoor unit, refer to “Precautions for Selecting the Location” and the “Indoor/Outdoor Unit Installation Drawings”.

2) If drain work is necessary, follow the procedures below.

3. Refrigerant Piping

2. Drain Work

1) Use B drain plug for drainage.

2)

If the drain port is covered by a mounting base or floor surface, place

additional foot bases of at least 1-3/16 inch in height under the outdoor unit’s

feet.

3) In cold areas, do not use a drain hose with the outdoor unit. (Otherwise,

drain water may freeze, impairing heating performance.)

If the outdoor unit is positioned higher than the indoor units.

If the one indoor unit is positioned higher than the outdoor

unit, and other indoor unit is positioned lower than it.

Outdoor unit capacity class

Piping to each indoor unit

Total length of piping between all units

2MXS18

82 ft max.

164 ft max.

Liquid pipe

19.5~23.8 ft-lbf

Gas pipe

35.5~44.0 ft-lbf

Valve cap tightening

torque

Service port cap

tightening torque

7.9~10.8 ft-lbf

1) Use the flare nut fixed to the main unit. (To prevent cracking of the flare nut by aged deterioration.)

2)

To prevent gas leakage, apply refrigeration oil only to the inner surface of the flare. (Use refrigeration oil for R410A.)

3) Use torque wrenches when tightening the flare nuts to prevent damage to the flare nuts and gas leakage.

Align the centres of both flares and tighten the flare nuts 3 or 4 turns by hand. Then tighten them fully with the torque wrenches.

CAUTION

Torque wrench

Piping union

Flare nut

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration oil to the

inner surface of the flare.

Do not apply refrigeration oil to the flare

nut avoid tightening with over torque.

Spanner

[Apply oil] [Tighten]

Loading...

Loading...