18 | Piping installation

Installer and user reference guide

88

REYQ8~20+REMQ5U7Y1B

VRV IV+ heat recovery

4P561154-1A – 2020.10

18.2.9 To braze the pipe end

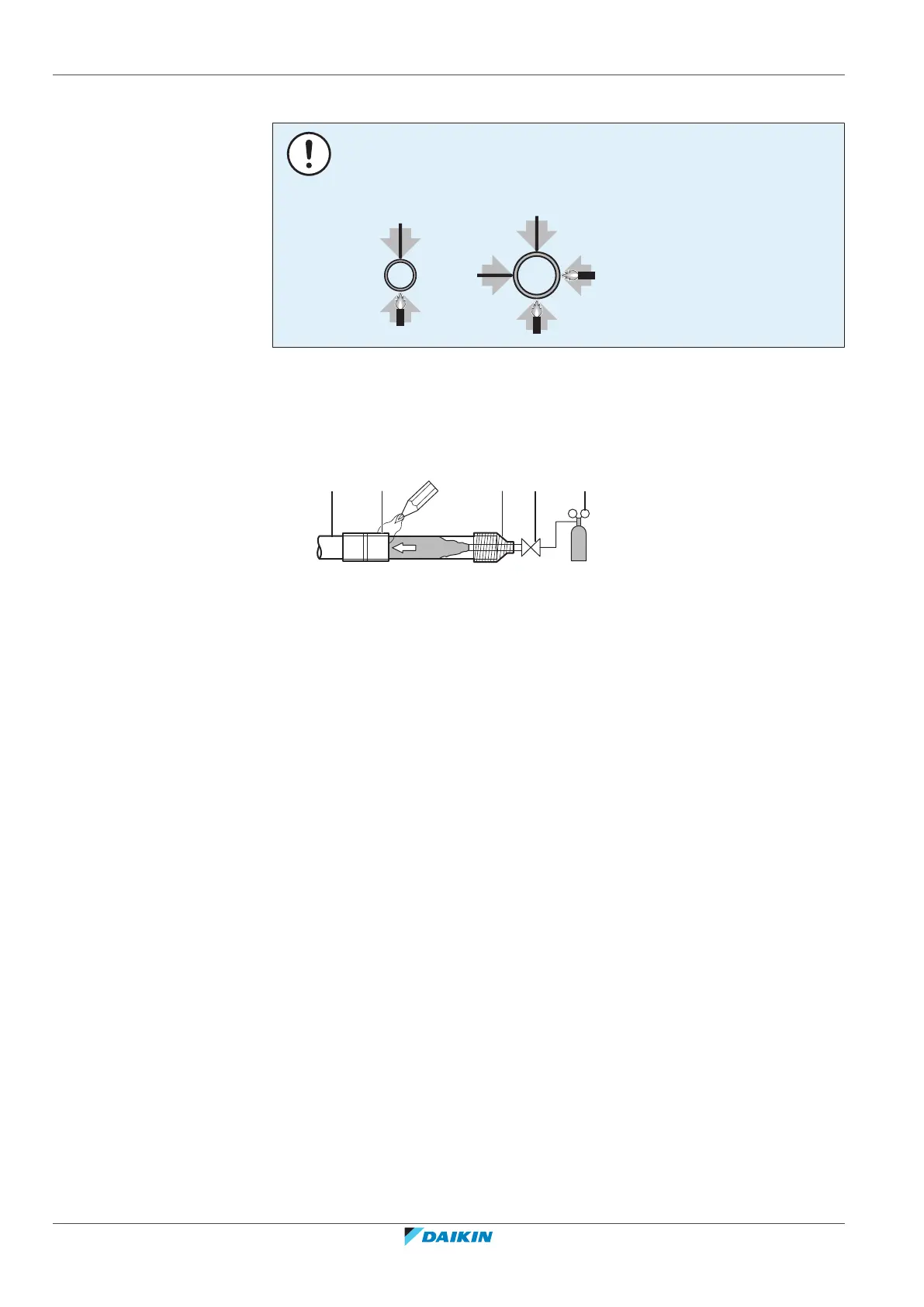

NOTICE

Precautions when connecting field piping. Add brazing material as shown in the

figure.

▪ When brazing, blow through with nitrogen to prevent creation of large quantities

of oxidised film on the inside of the piping. This film adversely affects valves and

compressors in the refrigerating system and prevents proper operation.

▪ Set the nitrogen pressure to 20kPa (0.2bar) (just enough so it can be felt on the

skin) with a pressure-reducing valve.

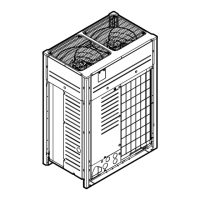

a Refrigerant piping

b Part to be brazed

c Taping

d Manual valve

e Pressure-reducing valve

f Nitrogen

▪ Do NOT use anti-oxidants when brazing pipe joints.

Residue can clog pipes and break equipment.

▪ Do NOT use flux when brazing copper-to-copper refrigerant piping. Use phosphor

copper brazing filler alloy (BCuP), which does not require flux.

Flux has an extremely harmful influence on refrigerant piping systems. For

instance, if chlorine based flux is used, it will cause pipe corrosion or, in

particular, if the flux contains fluorine, it will deteriorate the refrigerant oil.

▪ Always protect the surrounding surfaces (e.g. insulation foam) from heat when

brazing.

18.2.10 Using the stop valve and service port

To handle the stop valve

Take the following guidelines into account:

▪ Make sure to keep all stop valves open during operation.

▪ The gas and liquid stop valves are factory closed.

▪ The figures below show the name of each part required in handling the stop

valve.

Loading...

Loading...