IM 1131-2 5

Water Piping

Water Piping

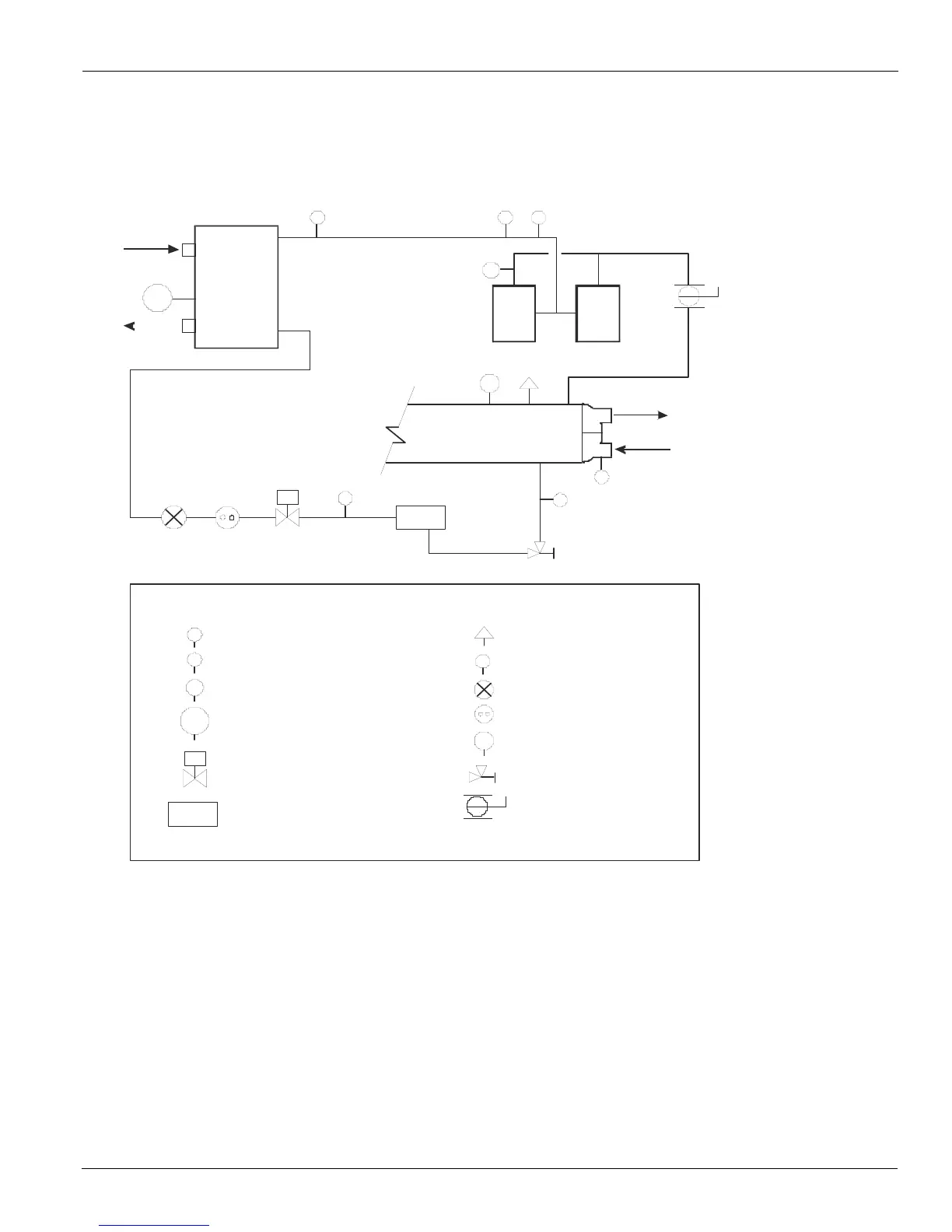

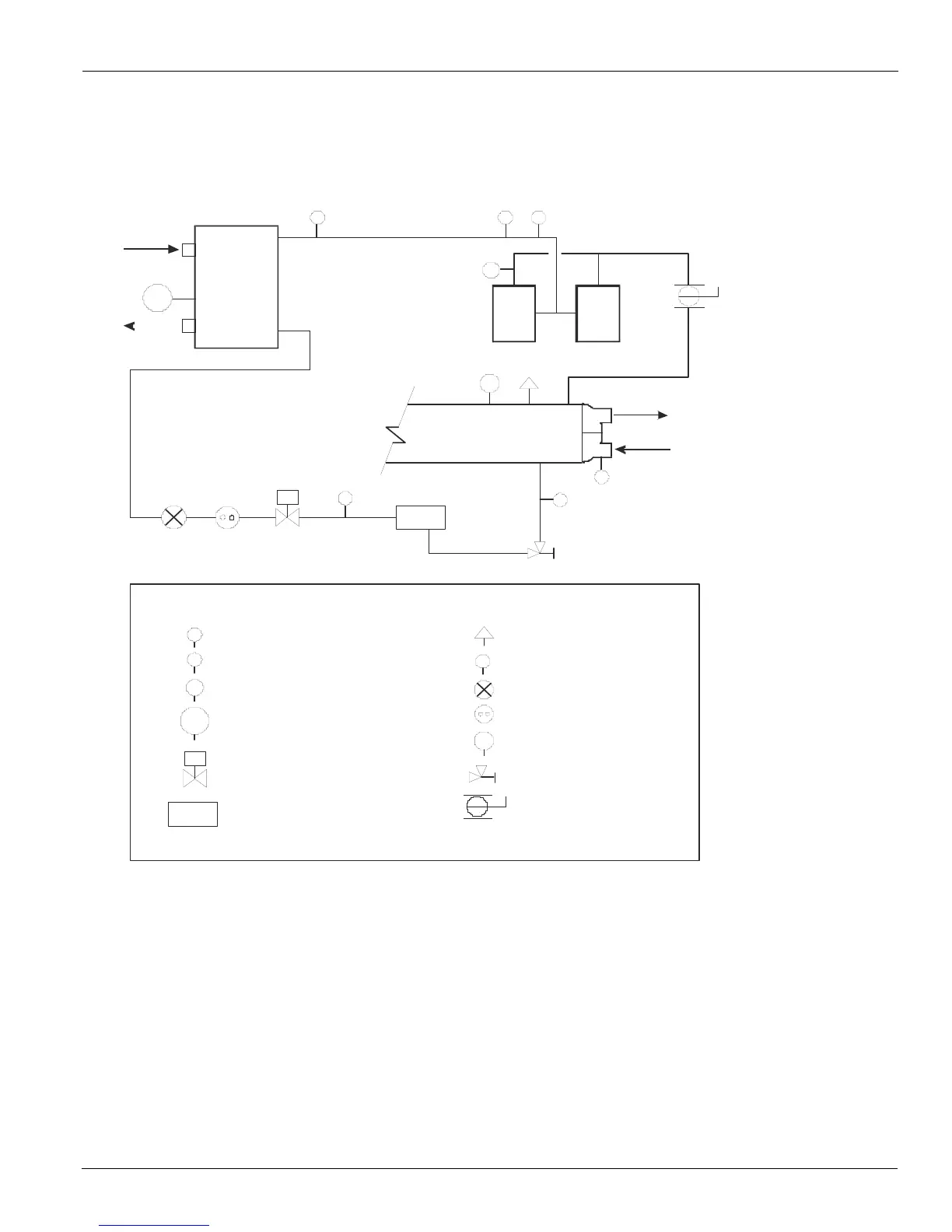

Unit Configuration

WGZ 030DW to 130DW have two refrigerant circuits, two

tandem scroll compressors (total of four), a single two-

circuited brazed plate evaporator, a single two-circuited water-

cooled condenser, interconnecting refrigerant piping and a

control panel with associated sensors and transducers. Models

WGZ 150DW to 200DW have two trio-compressors (total of

6) and a shell-and-tube evaporator.

Figure 1: Schematic Piping Diagram (One of Two Circuits for Brazed Plate Evaporators)

Install Vessel Drain Plugs at Start-up

Condensers are drained of water in the factory and are shipped

with the condenser drain plugs in the heads removed and

stored in a bag in the control panel. Be sure to replace plugs

prior to filling the vessel with fluid.

General Piping Guidelines

Due to the variety of piping practices, it is advisable to follow

the recommendations of local authorities for code compliance.

They can supply the installer with the proper building and

safety codes required for a safe and proper installation.

The piping should be designed with a minimum number of

bends and changes in elevation to keep system cost down and

performance up. Other piping design considerations include:

1 All piping should be installed and supported to prevent

the chiller connections from bearing any strain or weight

of the system piping.

2 Vibration eliminators to reduce vibration and noise

transmission to the building.

3 Shutoff valves to isolate the unit from the piping system

during unit servicing.

4 Do not use PVC or CPVC piping for any water lines.

Comp

#2

Comp

#1

Condenser

Condenser

Water

Evaporator

S

F-D

T

S

S

CV

SP

P

1

T

Legend:

Temperature Sensor

Pressure Transducer

Pressure (High Pressure Cutout)

Temperataure Sensor, Leaving

Chilled Water Control

T

T

T

P

P

1

LWT

Relief Valve

Schrader Fitting

Thermal Expansion

Valve

re In dicator

S

CV

Solenoid Valve

F-D Filter-Drier

Angle Valve

Ball Valve

NOTE:

Standard condenser

connections are on

the control panel end.

Loading...

Loading...