IOM 1274-3 • CENTRIFUGAL WATER CHILLERS 70 www.DaikinApplied.com

TechResponse@DaikinApplied.com.

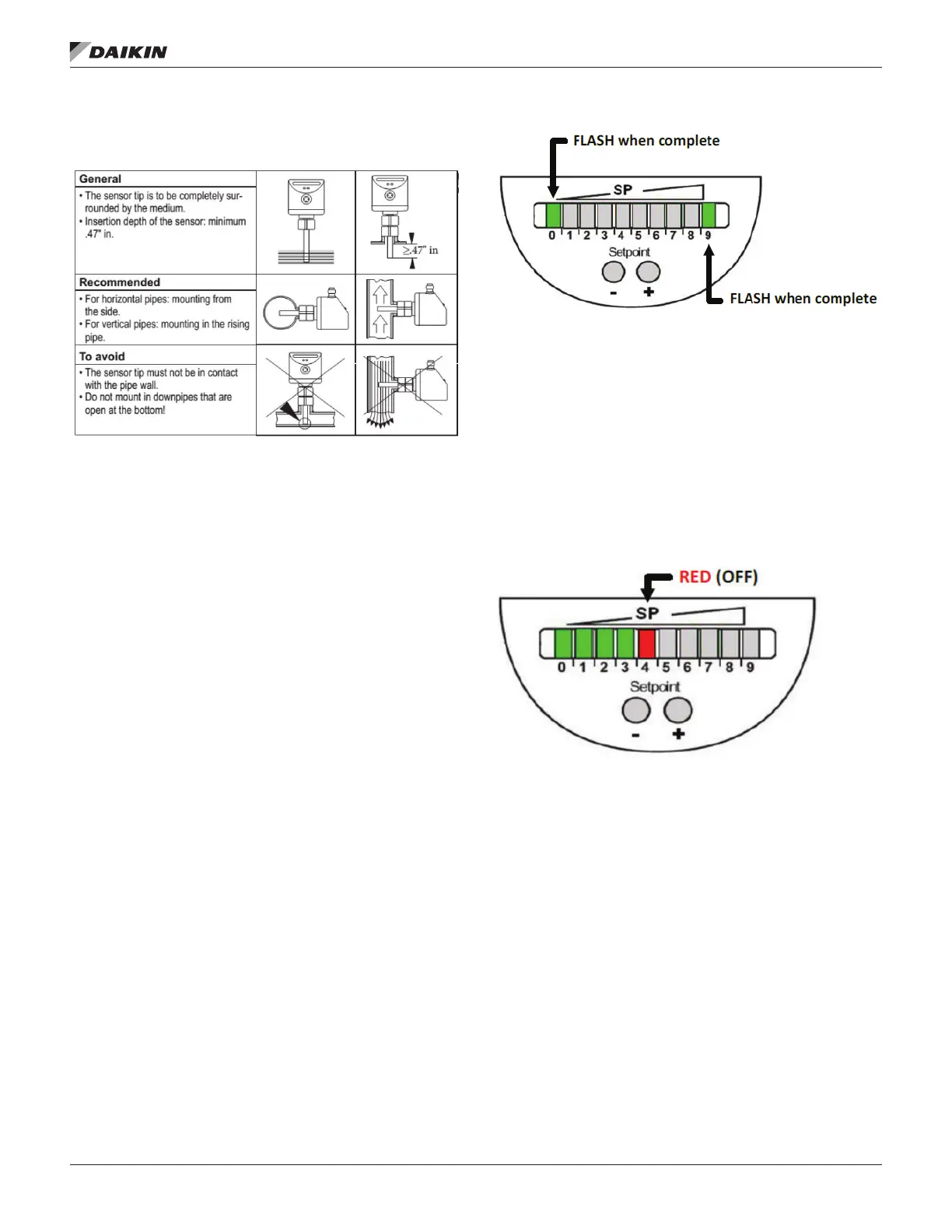

Figure 77: Remote Mounting Guidelines for Flow Switch

If needed, the adapter is threaded into the pipe using pipe

mounted onto the adapter using silicone grease. Carefully

apply lubricant to the inside threads and o-ring so temperature

probe does not become coated with lubricant. Torque the

adapter/sensor connection to 18.5 ft/lbs.

Wiring

Refer to wiring diagram in the unit control panel.

controller’s digital input is a DC signal which is supplied

It is required that the AC and DC commons of power be

separated. Contact Chiller Technical Response for alternate

wiring scenarios.

Flow Switch Setup

of 20 cm/s. This value is typically well below the minimum

4 are the calculated gallons per minute (gpm) for Schedule 40

to 300 cm/s.

1.

setup procedure.

2.

switch. The ‘Teach’ function is initiated by holding down

seconds. During this 15 second period, LEDs ‘0’ and ‘9’

will be lit green. Once the ‘Teach’ function is completed,

2.

Figure 78: Automatic Teach of Setpoint

3. After the ‘Teach’ function is completed and the outer

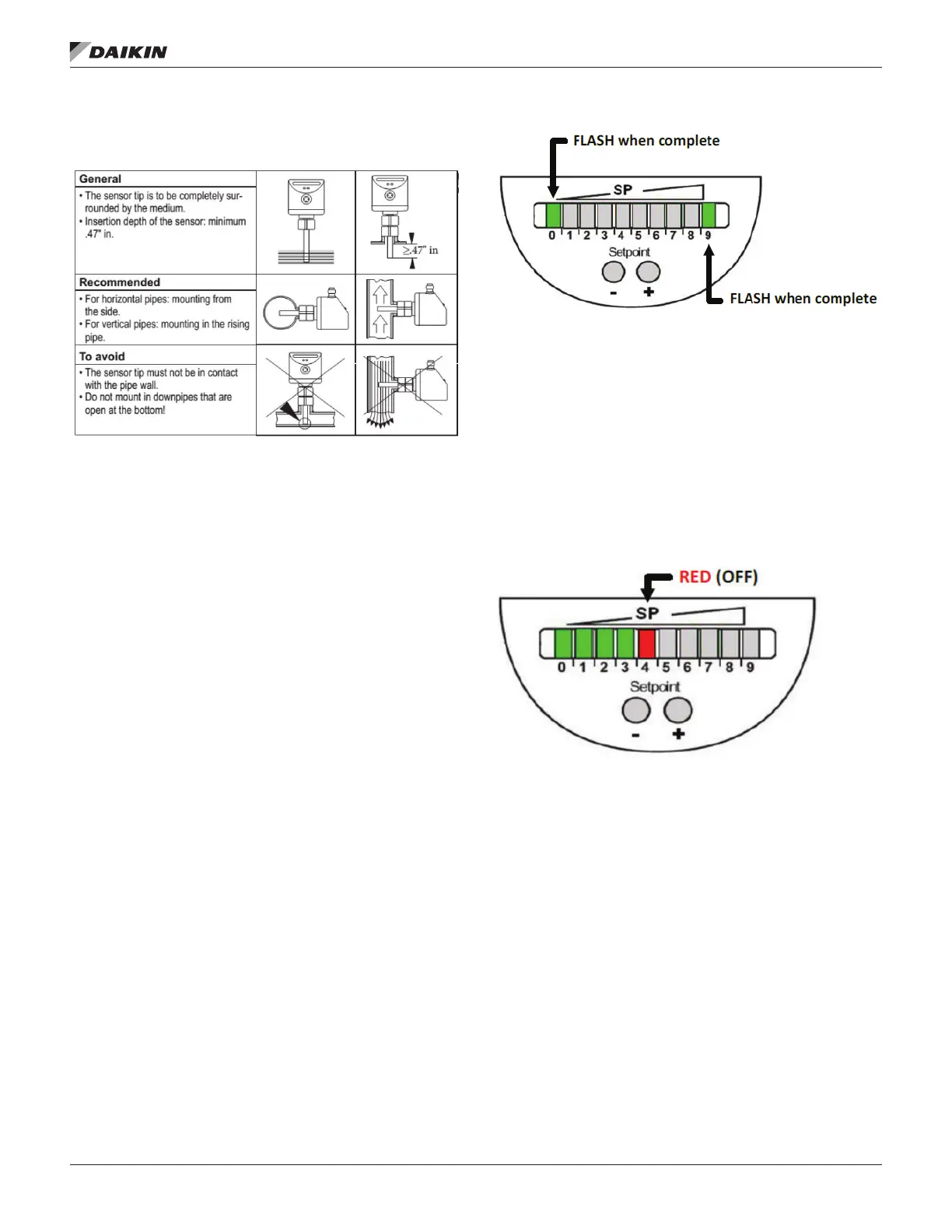

Figure

79 shows a typical display for this condition. All LEDs

to the left of the SP LED are lit green. The SP LED is

lit RED (or may toggle amber) which indicates that the

Figure 79: Teach Adjustment Complete

point within the desired operating range. Additional ‘manual’

adjustment of set point is required in order to allow for chiller

2.5 cm/s.

4.

shown in Figure 80

Loading...

Loading...