12 | RS8EU702 |

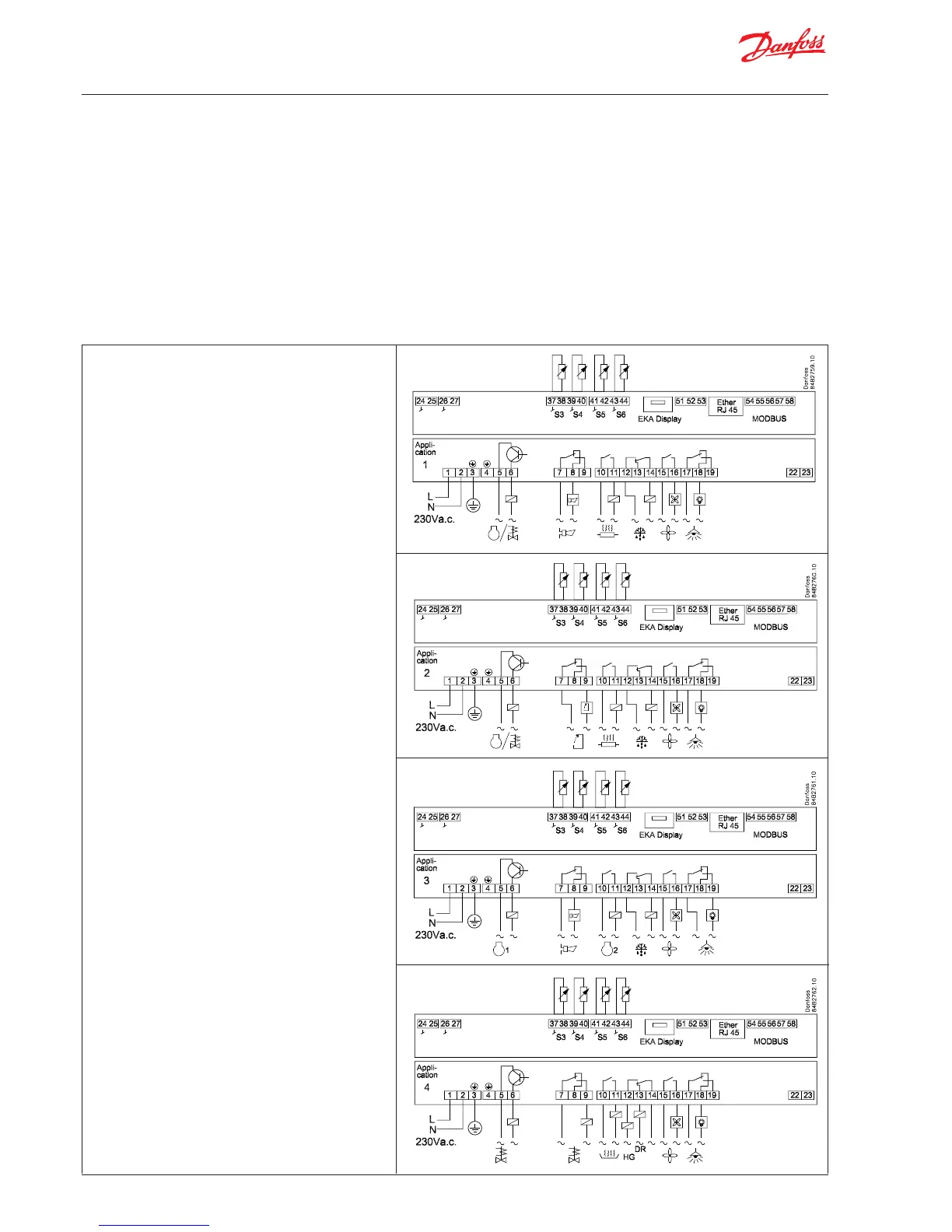

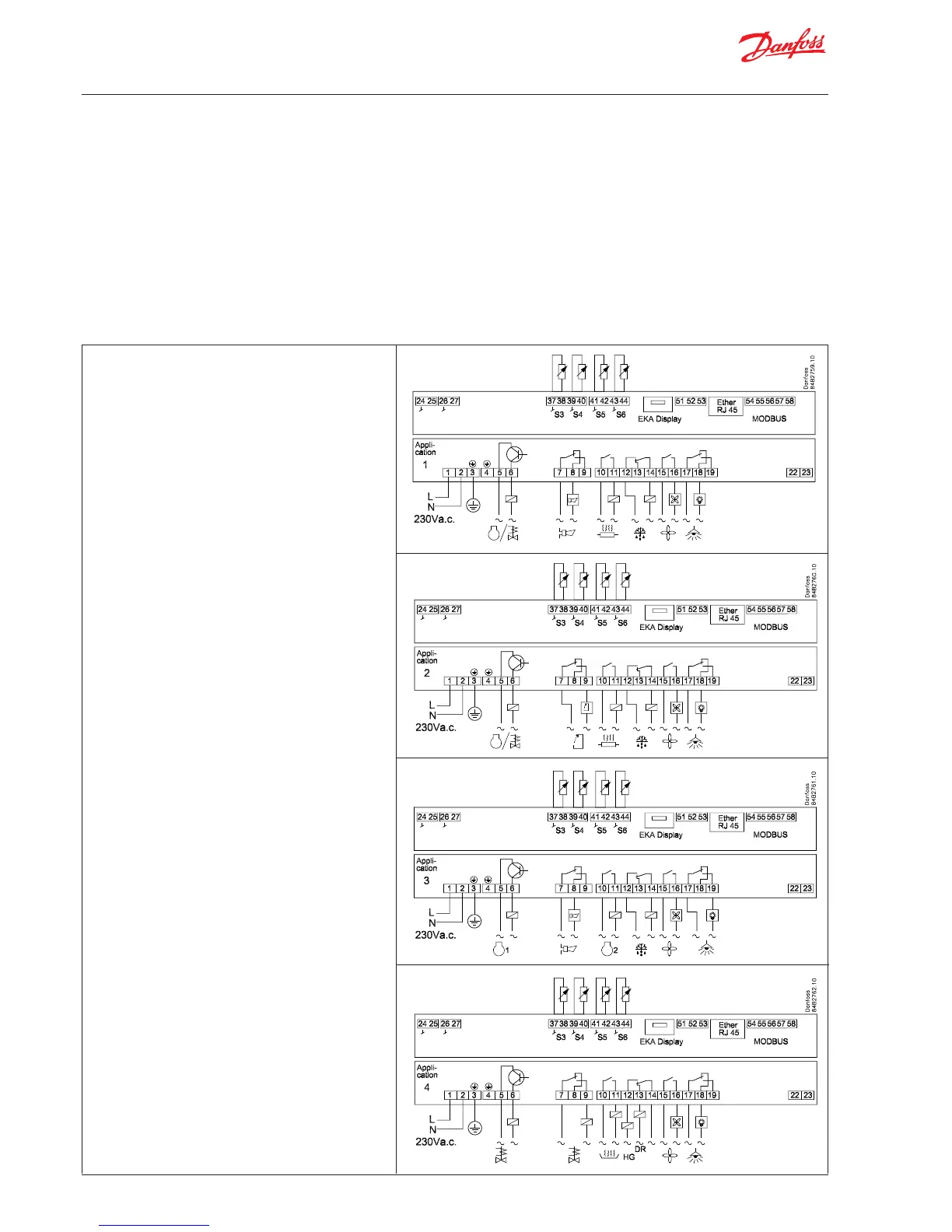

Applications

Here is a survey of the controller’s eld of application.

A setting will dene the relay outputs so that the

controller’s interface will be targeted to the chosen

application.

On page 28 you can see the relevant settings for the

respective wiring diagrams.

S3 and S4 are temperature sensors. The application will determine whether

either one or the other or both sensors are to be used. S3 is placed in the air

ow before the evaporator. S4 after the evaporator.

A percentage setting will determine how the control is to be based. S5 is a

defrost sensor and is placed on/in the ns of the evaporator.

S6 is a product sensor.

DI1, DI2 and DI3 are contact functions that can be used for one of the fol-

lowing functions: door function, alarm function, defrost start, external main

switch, night operation, change of thermostat reference, appliance cleaning,

forced refrigeration or coordinated defrost. DI3 has a 230 V input. See the

functions in settings o02, o37and o84.

2

3

4

General:

The eight applications are all adapted for

commercial refrigeration systems in the form of

either refrigeration appliances or cold storage

rooms.

In general all have outputs for:

• Solenoid valve or compressor

• Fan

• Defrost

• Light

In addition they have dierent uses and thereby

input and outputs.

Application 1

Standard applications.

Application 2

Control of night blinds

Night blinds follow the status of the light function

– when the light is switched on, the night blinds

are up and when the light is switched o, the night

blinds are down. In addition a digital input provides

the option of forced opening of the blinds so that

the appliance can be lled with products.

Application 3

”Two-compressor” operation.

The two compressors must be of the same size. On

start-up (after defrosting, operational stop, etc.)

both compressors are started with a set time shift.

One compressor starts at half the dierential so that

an optimum adaptation of compressor capacity

takes place for the current load in the appliance/

room. There is automatic runtime equalisation

during cyclic operation.

For a more detailed description please refer to

earlier sections in the manual.

Application 4

Hot gas defrosting.

Hot gas defrosting is adapted to commercial

appliances/rooms with limited system lling.

One relay controls the main valve in the suction

line.

A changeover relay controls both the hot gas valve

and the drain valve.

This means that there is no time delay between

stops of hot gas and start of draining.

1

Loading...

Loading...