130 Capacity controller RS8HE202 © Danfoss 2017-07 AK-PC 781A

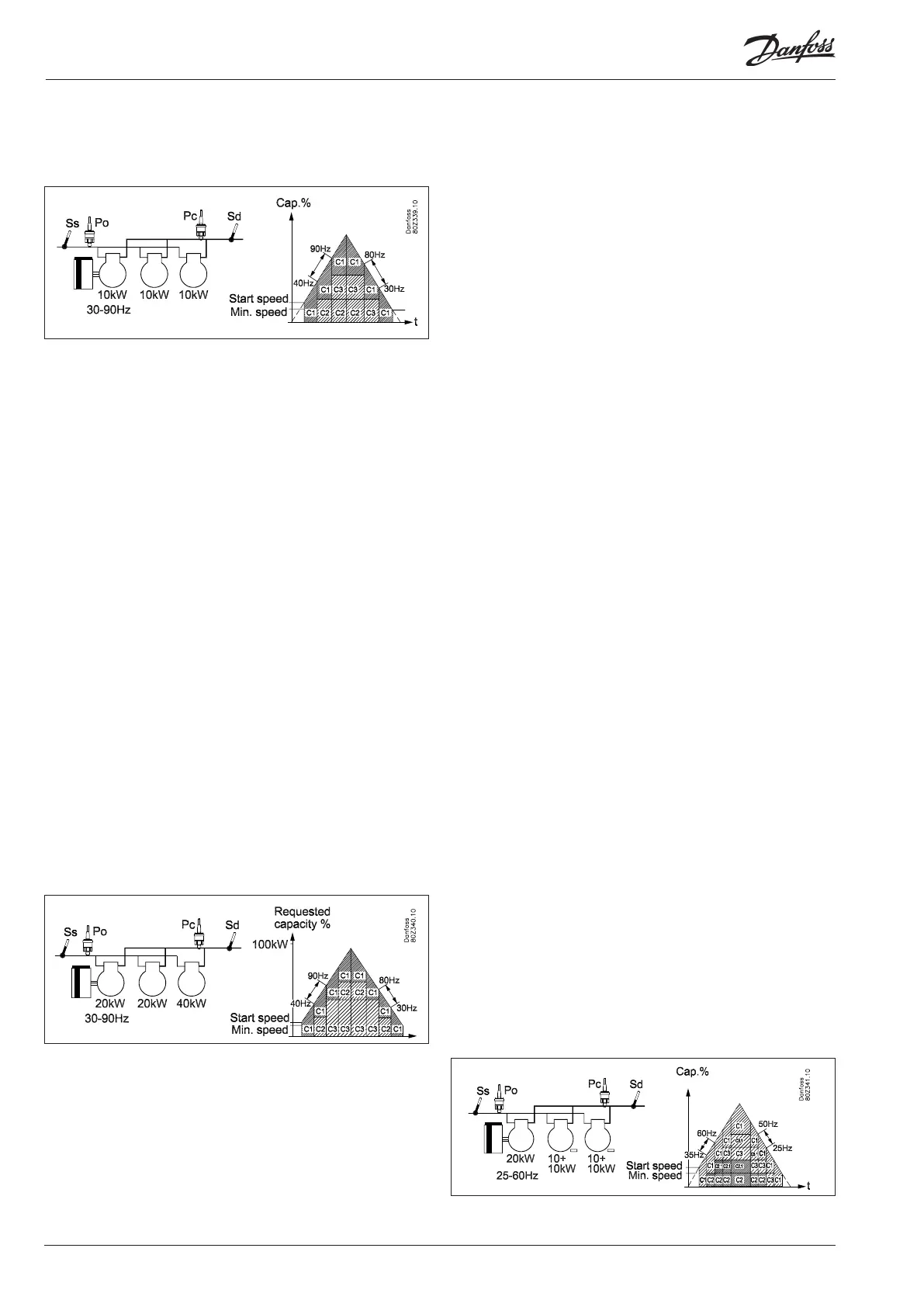

The speed-regulated compressor is used to fill the capacity gaps

between the one-step compressors.

Example:

Increasing capacity:

- The speed-regulated compressor starts when the desired

capacity equals the start speed

- The following one-step compressor with the smallest number

of operating hours cut in when the speed-regulated compres-

sor is running at full speed (90 Hz)

-When a one-step compressor cuts in, the speed-regulated com-

pressor reduces speed (40 Hz) equivalent to the capacity of the

one-step compressor.

Decreasing capacity:

- The following one-step compressors with the most operating

hours should be cut out when the speed-regulated compressor

reaches minimum speed (30 Hz)

- When a one-step compressor is cut out, the speed- regulated

compressor’s speed increases (80 Hz), equivalent to the capac-

ity of the one-step compressor

- The speed-regulated compressor is the last compressor to be

cut out when the preconditions for this are fulfilled.

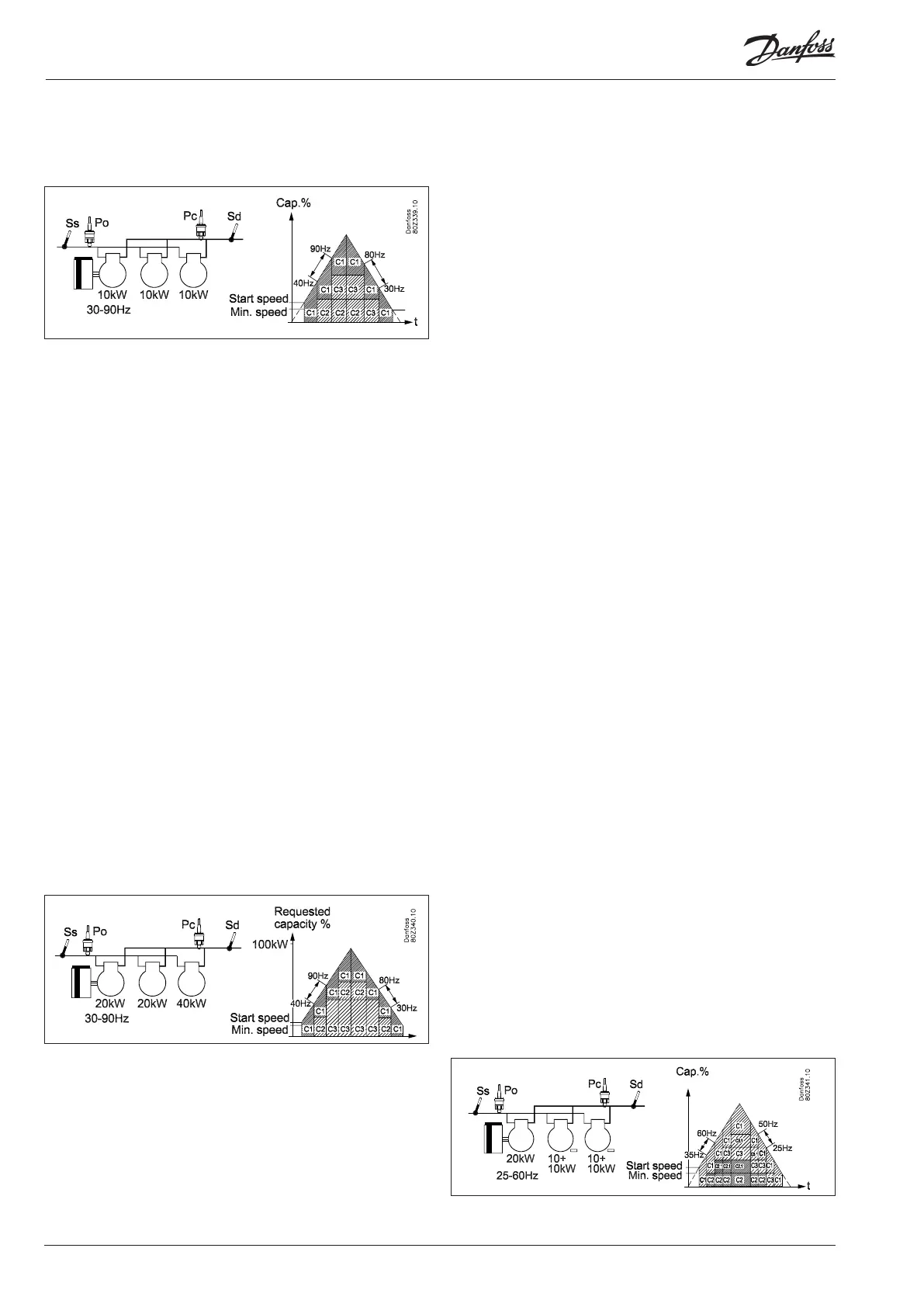

Best fit - example:

Here, at least two of the one-step compressors are of different

sizes.

The speed-regulated compressor is always the first to start and

last to stop.

The capacity distributor cuts in and cuts out the one-step com-

pressors in order to achieve the best possible capacity fit (least

possible capacity jump)

The speed-regulated compressor is used to fill out the capacity

gaps between the one-step compressors.

Example:

Increasing capacity:

- The speed-regulated compressor starts when the desired

capacity matches the start speed

- The smallest one-step compressor is cut in when the speed-

regulated compressor runs at full-speed (90 Hz).

- When the speed-regulated compressor again reaches max.

speed (90 Hz), the smallest one-step compressor is cut out (C2)

and the big one-step compressor (C3) is cut in.

- When the speed-regulated compressor again reaches max

speed (90 Hz), the smallest one-step compressor (C2) is cut in

again.

- When the one-step compressor is cut in, the speed is reduced

on the speed-regulated compressor (40 Hz) equivalent to the

capacity of the cut in capacity

Decreasing capacity:

- The small one-step compressor is cut out when the speed-regu-

lated compressor has reached minimum speed (30 Hz)

- When the speed-regulated compressor again reaches minimum

speed (30 Hz), the smallest one-step compressor (C2) is cut out

and the big one-step compressor (C3) is cut in.

- When the speed-regulated compressor again reaches min.

speed (30 Hz), the large one-step compressor (C3) is cut out

and the small one-step compressor (C2) is cut in again.

- When the speed-regulated compressor again reaches min.

speed (30 Hz), the small one-step compressor (C2) is cut in.

- The speed-regulated compressor is the last compressor to be

cut out when the requirements for this are fulfilled.

- When the one-step compressor’s capacity is cut out, the speed-

regulated compressor increases speed (80 Hz) equivalent to

the cut out capacity.

Compressor application 6 – 1 x Speed + unloader

The controller can operate one speed-regulated compressor com-

bined with several capacity-regulated compressors of the same

size and with the same number of unloaders.

The advantage of this combination is that the variable part of the

speed-regulated compressor only needs to be large enough to

cover the following unload valves in order to achieve a capacity

curve without gaps.

Preconditions for using this compressor application are:

• A single speed-regulated compressor that can be of a different

size than the following compressors

• The capacity-regulated compressors are the same size and have

the same number of unload valves (max. 3)

• The main step on the capacity-regulated compressors are the

same size

• The main step and the unload valves can be different sizes, i.e.

50%, 25% and 25%.

This compressor combination can be handled in the following

coupling patterns:

• Cyclical

Handling the speed-regulating compressor.

For further information on the general handling of the speed-

regulated compressor, refer to section "Power pack types".

Cyclical operation - example

The speed-regulated compressor is always the first to start and

last to stop.

The capacity-regulated compressors are cut in and cut out in ac-

cordance with the First-in-First-Out principle in order to equalise

operating hours

The speed-regulated compressor is used to fill the ca-

pacity gaps between the unload valves/main steps.

Loading...

Loading...