70 | 180R9346 | AQ240486503020en-001702 © Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

Operating/Assembly instructions

Type HEW, HEW Compact and HEW-ZS

Sheet:

of 22

Please observe protection

note ISO 16016.

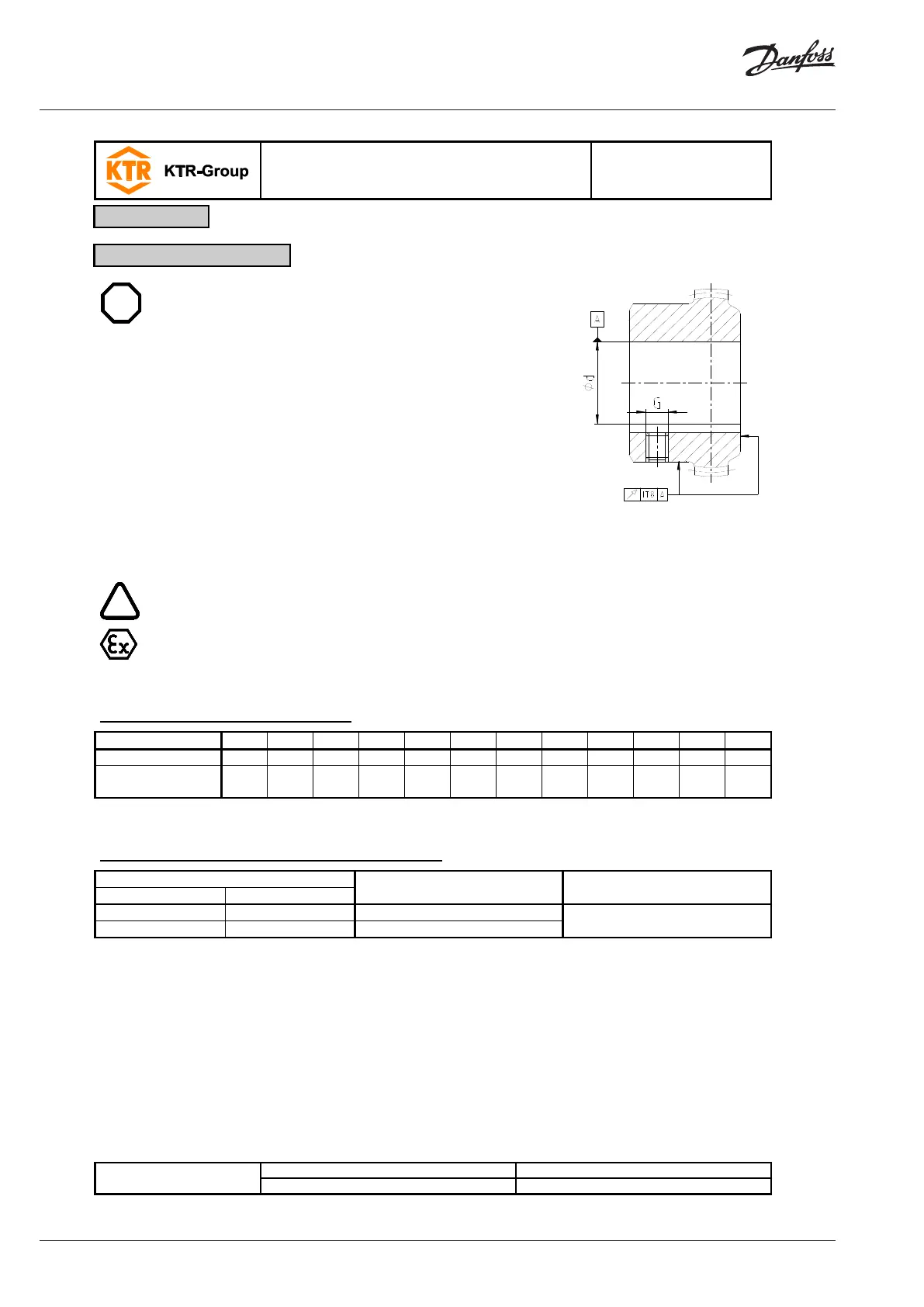

The maximum permissible bore diameters d (see table 1 to 5

in chapter 1 - technical data) must not be exceeded. If these

figures are disregarded, the coupling may tear. Rotating par-

ticles may cause danger to life.

Bores on the hubs/coupling flange machined by the customer

have to observe concentricity or axial runout (see illustration

12).

Please make absolutely sure to observe the figures for Ø d

max

.

Carefully align the hub or coupling flange when the finish

bores are drilled.

Provide for a setscrew according to DIN EN ISO 4029 with a

cup point or an end plate to fasten the hub or coupling flange

axially.

Illustration 12: Concentricity and axial

The customer bears the sole responsibility for all machining processes performed subse-

quently on unbored or pilot bored as well as finish machined coupling components and

spare parts. KTR does not assume any warranty claims resulting from insufficient rema-

chining.

Table 7: Setscrews DIN EN ISO 4029

Tightening torque

T

A

[Nm]

10 10 17 17 17 40 80 80 80 80 140 140

Table 8: Recommended fit pairs acc. to DIN 748/1

Shaft tolerance Bore tolerance

If a feather keyway is intended to be used in the hub, it should correspond to the tolerance ISO JS9 (KTR stand-

ard) with normal operating conditions or ISO P9 with difficult operating conditions (frequently alternating torsional

direction, shock loads, etc.).

The transmittable torque of the shaft-hub-connection must be reviewed by the customer and is subject to his re-

sponsibility.

4 Assembly

4.2 Advice for finish bore

Loading...

Loading...