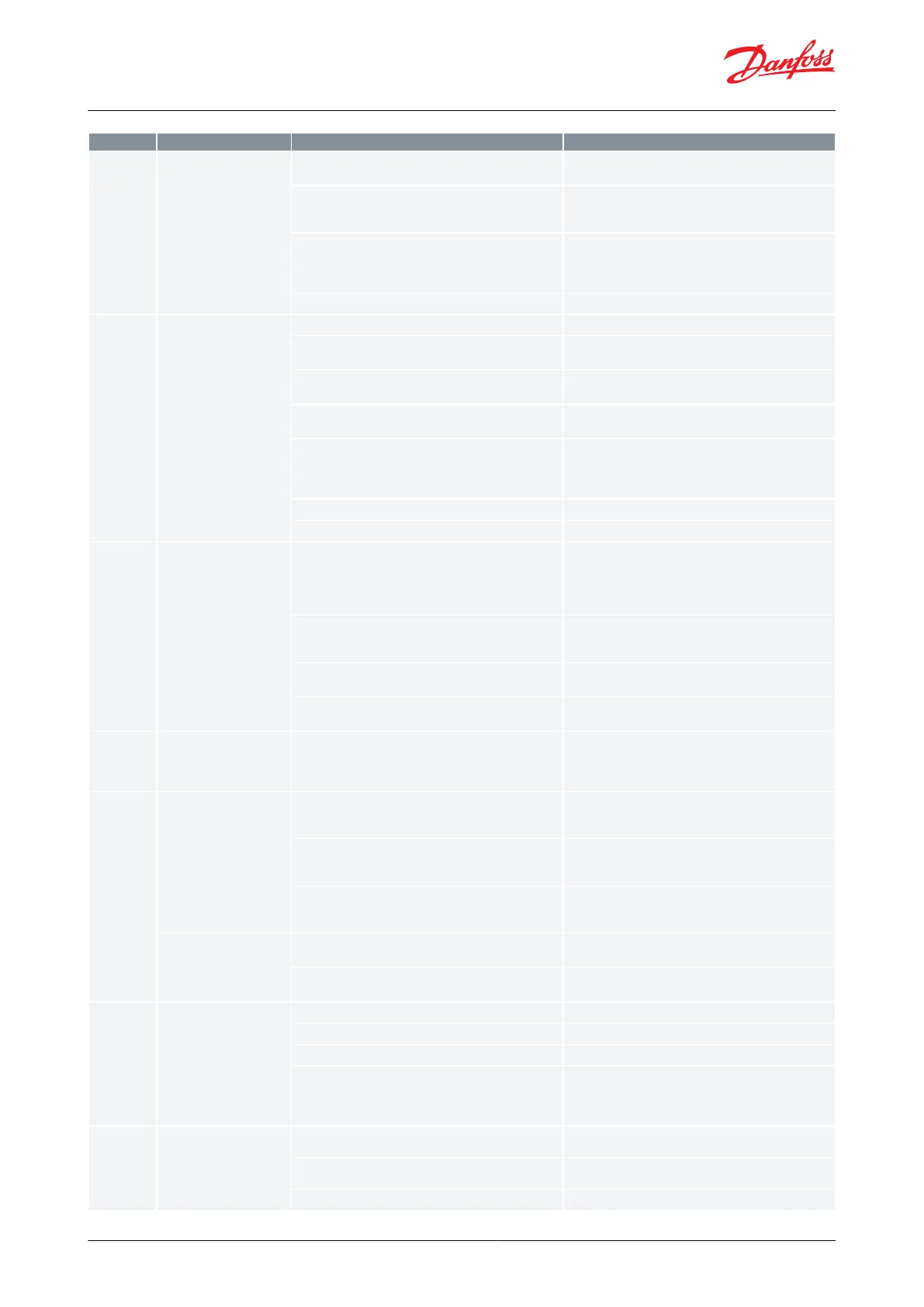

Liquid hammer in compres-

sor (noisy or unusual com-

pressor sound) and /or frost

on the suction line

Superheat reference set too low.

• Increase the SH reference by changing the SH min.

max. parameter.

• Make sure SH Close function is ON.

• Increase the values of SH close and SH min.

• Also check section "Too low superheat"

Inaccurate SH measurement or slow response in S2 sen-

sors.

• Ensure that S2 sensor is secured on suction line.

• Insulate temperature sensor properly.

• Check the product installation guide section tempera-

ture sensor.

Refrigerant or pressure transmitter is not set correctly.

• Check the related parameters.

Min. SH parameter is too low set.

• Raise the min. SH parameter.

Valve Cannot Close fully.

• Reduced the Valve OD or forced opening time at Start

up.

Valve OD too large at start up.

• Use P-control.

• Reduce Start OD.

• Mounting position of Temperature sensor. Place sensor

close to evaporator.

High-pressure drop-in suction line.

• Mounting position of the pressure transmitter. Place

the transmitter close to evaporator.

• Check the product installation guide section tempera-

ture sensor.

• Check valve installation.

Liquid returns to compressor.

• Check section Liquid hammering.

• Limit max opening degree of the valve setting in con-

troller.

• Check refrigeration system capacity and compare with

expansion valve capacity. Use proper valve size suitable

for the system.

Controller is not setup/tuned properly.

• Check the controller superheat settings SH min, SH max

and sensors connected to it.

• Tune PID parameters in the controller.

Wrong valve selected from the controller list or undersized

valve installed.

• Check the right valve type and setting or use the ap-

propriate valve size for the needed condition.

Seasonally high load condition or overloaded the system.

• Check the heat exchanger for dirt's.

• Check superheat performance.

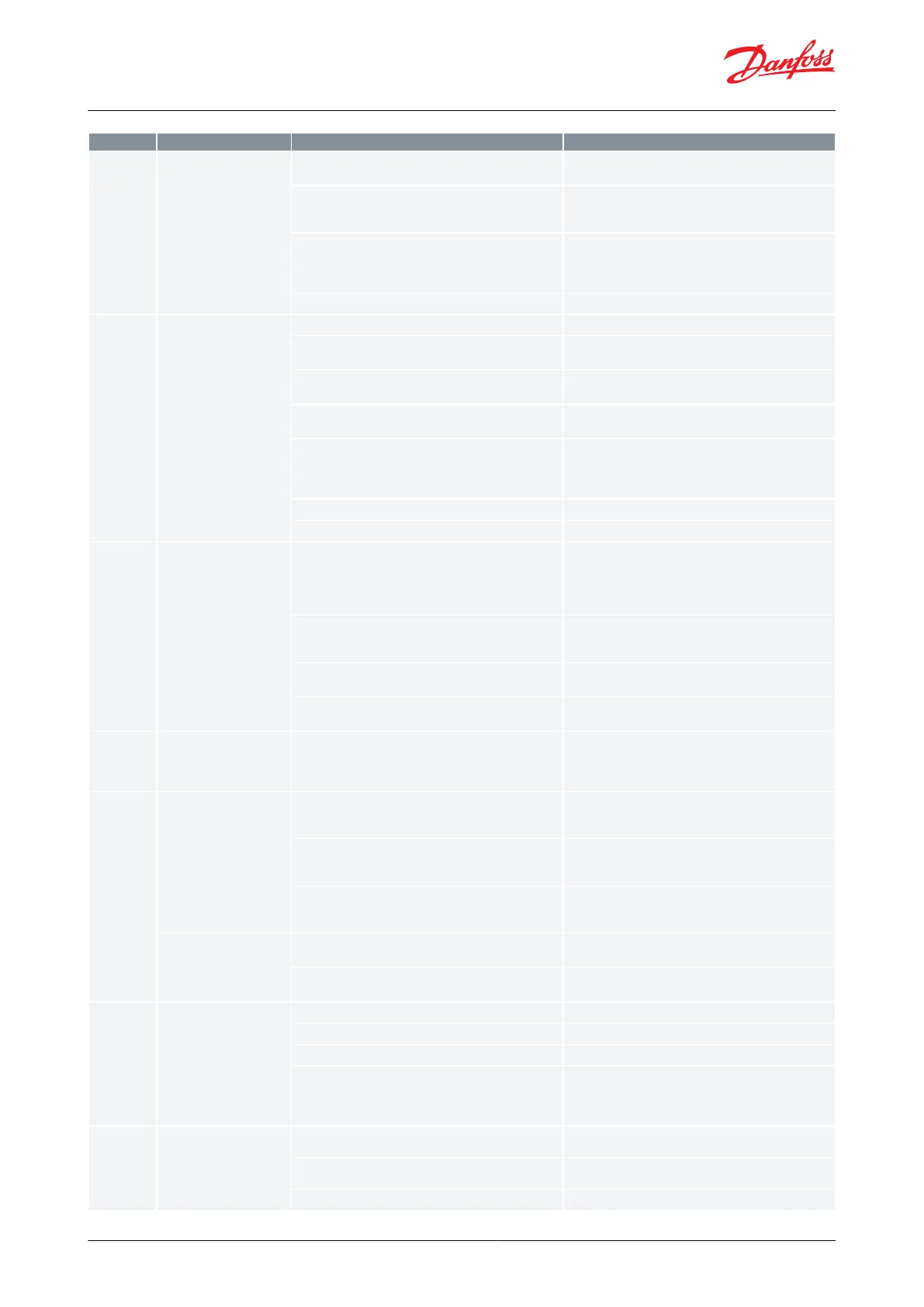

Too high or too low meas-

ured superheat

Wrong sensor type, refrigerant type, pressure transmitter

type and/or range.

• Check the related setting and range.

• In case of oset in sensor or pressure transmitter, per-

form the sensor correction.

• Always use accurate pressure transmitter

Measured Superheat is

higher than reference -

more than 5K for 5 - 10 min.

Load condition has changed, and the superheat controller

is too slow to adapt to the change.

• TN can be adjusted to 20% lower and Kp can be adjus-

ted to be 20% higher, monitor that the adjustment

doesn’t make the valve OD and Pe/Te oscillate.

Compressor capacity has changed, and the superheat con-

troller is too slow to adapt to the change.

• Compensation for compressor change is done with

KpTe in this case KpTe can be adjusted to be 20% high-

er.

• Check if valve OD is close to 100 %, if so, the valve is

missing capacity, check if sub cooling is OK.

• System might have loss charge.

Measured Superheat is low-

er than reference - lower 3K

SH close parameter is disabled or not setup optimally.

• Enable the SH close function and set the setpoint 2K

below the reference.

Compressor capacity has changed, and the superheat con-

troller is act too aggressive to adapt to the change.

• Compensation for compressor change is done with

KpTe in this case KpTe can be adjusted to be 20% lower.

The S2 sensor not in good contact with the suction line.

• Check proper mounting of the temperature sensor.

Fast change in load and ambient condition.

• Wait for the stable condition and check again.

Periodic ash gas at the valve inlet.

• Secure stable sub cooling

Aggressive gain Kp and Kp Te parameter.

• Decrease gain in the controller, ex set SH Tn to be 20 %

higher and reduce Kp 20%, if still SH is uctuating, re-

duce KpTe by 20%.

• Try with the higher SH reference.

Wrong sensor type, refrigerant type, pressure transmitter

type and range.

• Check the related setting and range.

During start up suction pressure is low because of low Am-

bient temperature.

• Check the startup problem.

© Danfoss | Climate Solutions | 2022.06 BC398828796060en-000101 | 77

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Loading...

Loading...