3-17 Reference Resource 3

Option: Function:

Select the reference input to be used

for the third reference signal.

3-15 Reference Resource 1,

3-16 Reference Resource 2 and

3-17 Reference Resource 3 define up to

three different reference signals. The

sum of these reference signals

defines the actual reference.

[0] No function

[1] Analog input 53

[2] Analog input 54

[7] Frequency input 29

[8] Frequency input 33

[11]

*

Local bus reference

[20] Digital pot.meter

[21] Analog input X30-11

[22] Analog input X30-12

[29] Analog Input X48/2

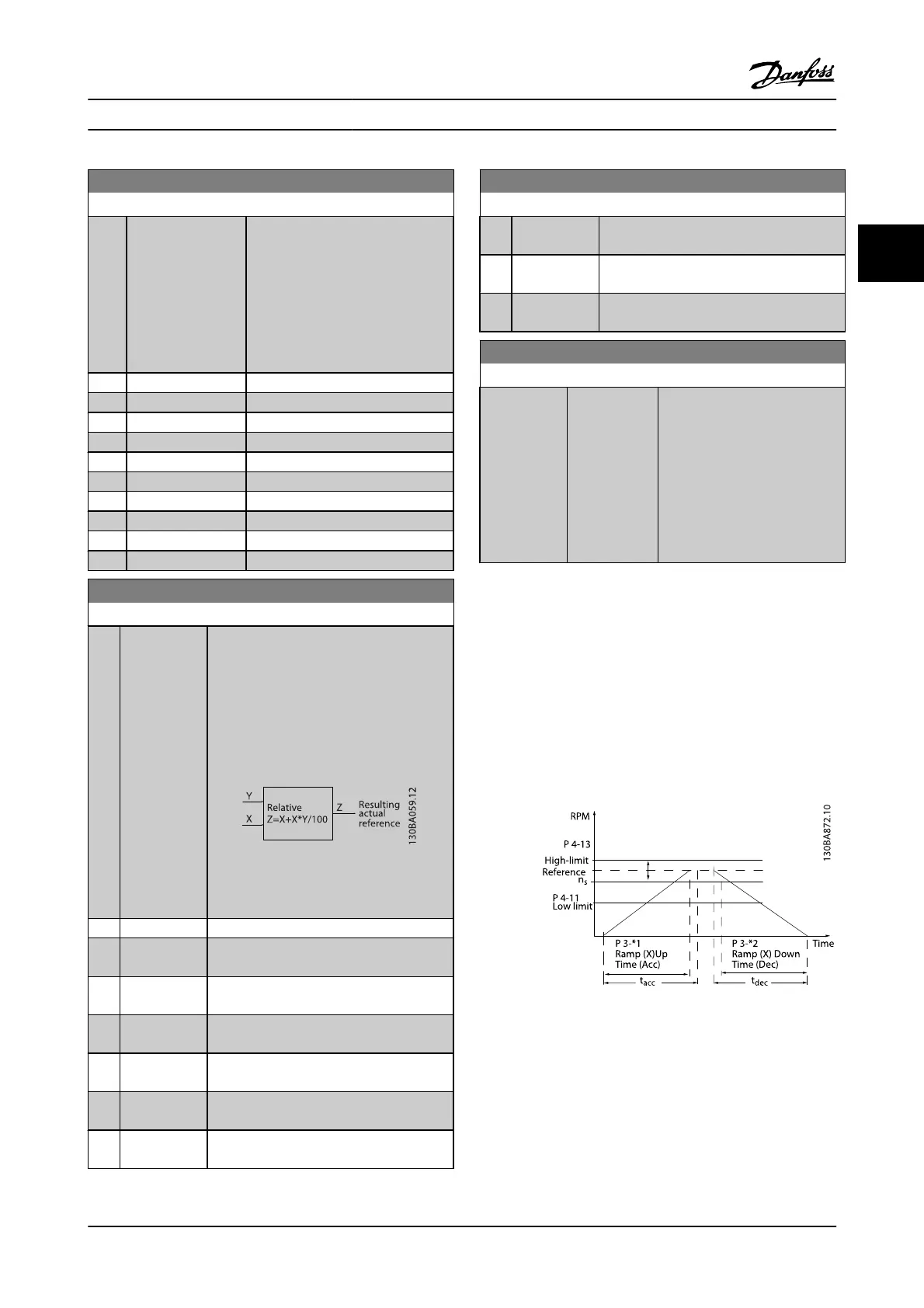

3-18 Relative Scaling Reference Resource

Option: Function:

Select a variable value to be added to the

fixed value (defined in 3-14 Preset Relative

Reference). The sum of the fixed and variable

values (labeled Y in the figure below) is

multiplied by the actual reference (labeled X

in the figure below). The result is then added

to the actual reference (X+X*Y/100) to give

the resulting actual reference.

This parameter cannot be adjusted while the

motor is running.

[0]

*

No function

[1] Analog input

53

[2] Analog input

54

[7] Frequency

input 29

[8] Frequency

input 33

[11] Local bus

reference

[20] Digital

pot.meter

3-18 Relative Scaling Reference Resource

Option: Function:

[21] Analog input

X30-11

[22] Analog input

X30-12

[29] Analog Input

X48/2

3-19 Jog Speed [RPM]

Range: Function:

Application

dependent

*

[Application

dependant]

Enter a value for the jog speed

n

JOG

, which is a fixed output

speed. The adjustable frequency

drive runs at this speed when the

jog function is activated. The

maximum limit is defined in

4-13 Motor Speed High Limit

[RPM].

See also 3-80 Jog Ramp Time.

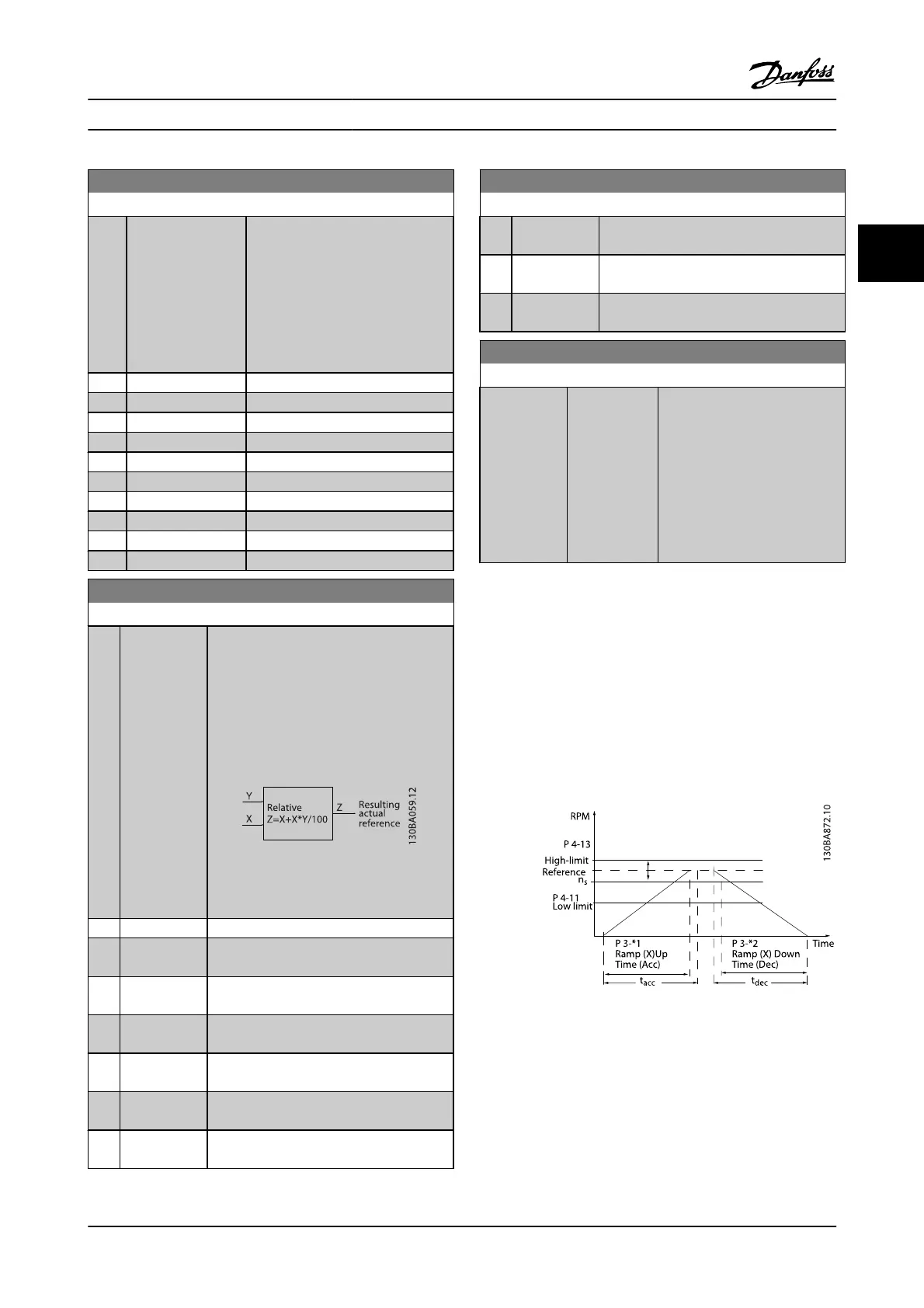

3.5.3 Ramps

3-4* Ramp 1

For each of four ramps (par. group 3-4*, 3-5*, 3-6* and 3-7*),

configure the ramp parameters: ramp type, ramping times

(duration of acceleration and deceleration) and level of jerk

compensation for S ramps.

Start by setting the linear ramping times corresponding to

the figures.

If S-ramps are selected, then set the level of non-linear jerk

compensation required. Set jerk compensation by defining

the proportion of ramp-up and ramp-down times where

acceleration and deceleration are variable (i.e., increasing or

decreasing). The S-ramp acceleration and deceleration

settings are defined as a percentage of the actual ramp time.

Parameter Descriptions FC 300 Programming Guide

MG.33.MA.22 - VLT

®

is a registered Danfoss trademark 3-35

3

Loading...

Loading...