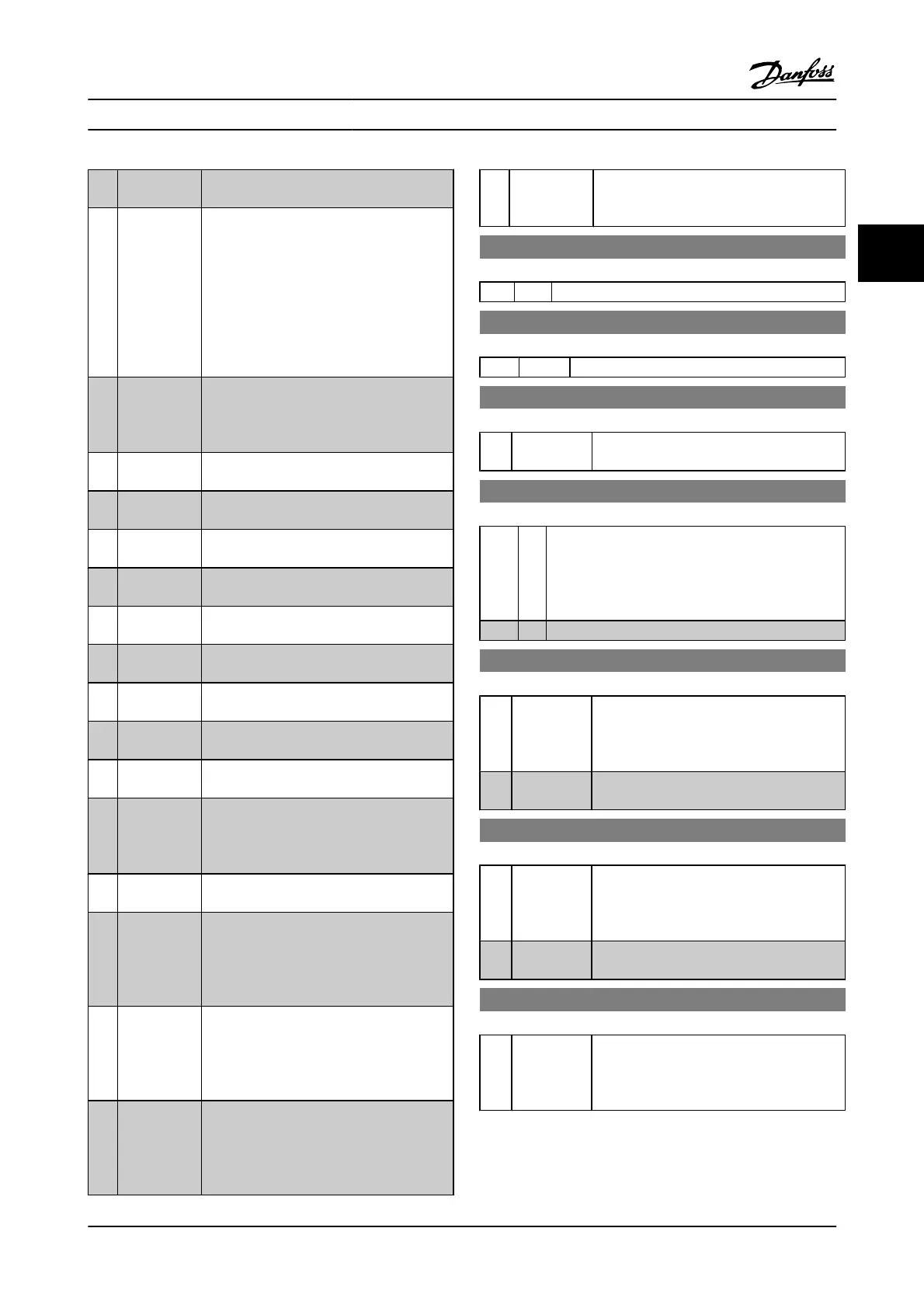

[36] Mains failure

inverse

Activates 14-10 Line Failure. Line failure inverse

is active in the logic .0. situation.

[40] Latched

Precise Start

A latched precise start only requires a pulse of

3ms on T18 or T19.

When using for 1-83 [1] or [2]:

When the reference is reached, the adjustable

frequency drive will internally enable the

precise stop signal. This means that the

adjustable frequency drive will do the precise

stop when the counter value of Par. 1-84 is

reached.

[41] Latched

Precise Stop

inverse

Sends a latched stop signal when the precise

stop function is activated in 1-83 Precise Stop

Function. The latched precise stop inverse

function is available for terminals 18 or 19.

[55] DigiPot

Increase

INCREASE signal to the digital potentiometer

function described in par. group 3-9*

[56] DigiPot

Decrease

DECREASE signal to the digital potentiometer

function described in par. group 3-9*

[57] DigiPot Clear Clears the digital potentiometer reference

described in par. group 3-9*

[60] Counter A (Terminal 29 or 33 only) Input for increment

counting in the SLC counter.

[61] Counter A (Terminal 29 or 33 only) Input for decrement

counting in the SLC counter.

[62] Reset Counter

A

Input for reset of counter A.

[63] Counter B (Terminal 29 or 33 only) Input for increment

counting in the SLC counter.

[64] Counter B (Terminal 29 or 33 only) Input for decrement

counting in the SLC counter.

[65] Reset Counter

B

Input for reset of counter B.

[70] Mech. Brake

Feedback

Brake feedback for hoisting applications: Set

1-01 Motor Control Principle to [3] flux w/ motor

feedback; set 1-72 Start Function to [6] Hoist

mech brake Ref.

[71] Mech. Brake

Feedback inv.

Inverted brake feedback for hoisting

applications

[72] PID error

inverse

When enabled, it inverts the resulting error

from the process PID controller. Available only

if "Configuration Mode" is set to "Surface

Winder," "Extended PID Speed OL" or

"Extended PID Speed CL."

[73] PID reset I-

part

When enabled, resets the I-part of the process

PID controller. Equivalent to 7-40 Process PID

I-part Reset. Available only if "Configuration

Mode" is set to "Surface Winder," "Extended

PID Speed OL" or "Extended PID Speed CL."

[74] PID enable When enabled, enables the extended process

PID controller. Equivalent to 7-50 Process PID

Extended PID. Available only if "Configuration

Mode" is set "Extended PID Speed OL" or

"Extended PID Speed CL."

[80] PTC Card 1 All digital inputs can be set to PTC card 1 [80].

However, only one digital input must be set to

this choice.

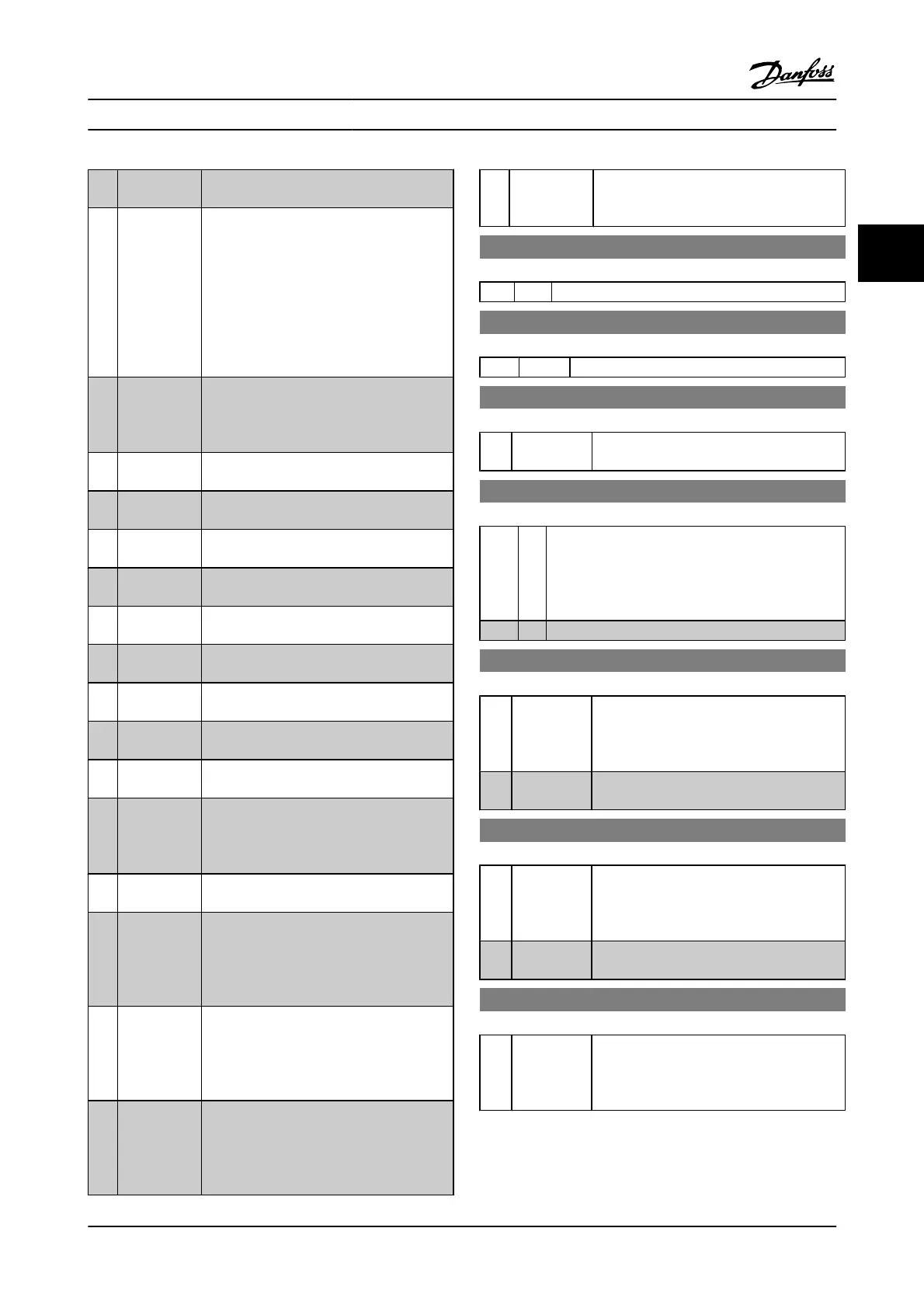

5-10 Terminal 18 Digital Input

Option: Function:

[8]

*

Start Functions are described under 5-1* Digital Inputs

5-11 Terminal 19 Digital Input

Option: Function:

[10]

*

Reverse Functions are described under 5-1* Digital Inputs

5-12 Terminal 27 Digital Input

Option: Function:

[2]

*

Coast inverse Functions are described under 5-1* Digital

Inputs

5-13 Terminal 29 Digital Input

Option: Function:

Select the function from the available digital input

range and the additional options [60], [61], [63] and

[64]. Counters are used in Smart Logic Control

functions. This parameter is available for the FC 302

only.

[14]

*

Jog Functions are described under 5-1* Digital Inputs

5-14 Terminal 32 Digital Input

Option: Function:

Select the function from the available digital

input range and the additional options [60],

[61], [63] and [64]. Counters are used in Smart

Logic Control functions.

[0]

*

No operation Functions are described under 5-1* Digital

Inputs

5-15 Terminal 33 Digital Input

Option: Function:

Select the function from the available digital

input range and the additional options [60],

[61], [63] and [64]. Counters are used in Smart

Logic Control functions.

[0]

*

No operation Functions are described under 5-1* Digital

Inputs

5-16 Terminal X30/2 Digital Input

Option: Function:

[0]

*

No operation This parameter is active when option module

MCB101 is installed in the adjustable

frequency drive. Functions are described

under 5-1* Digital Inputs

Parameter Descriptions FC 300 Programming Guide

MG.33.MA.22 - VLT

®

is a registered Danfoss trademark 3-51

3

Loading...

Loading...