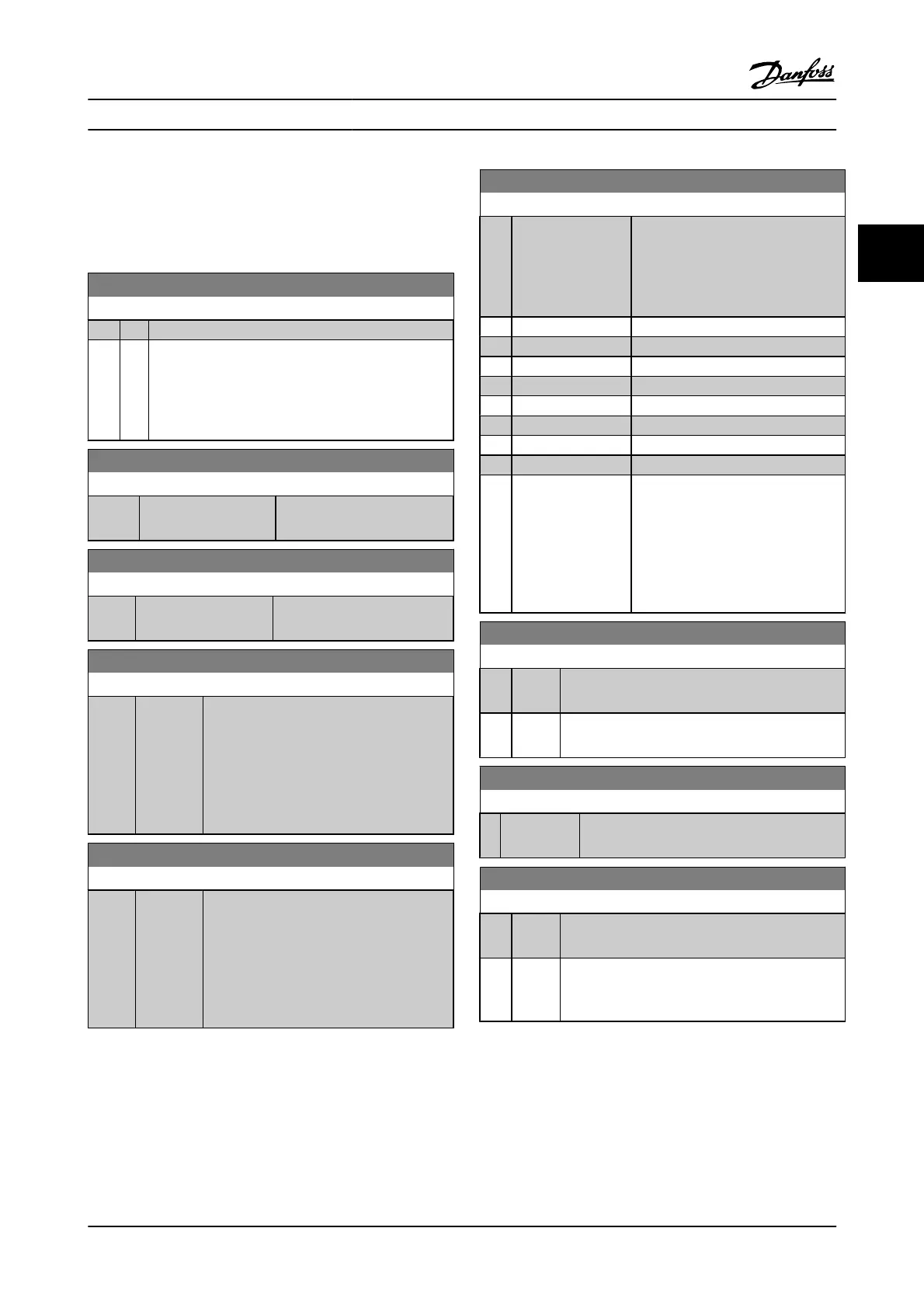

3.9.5 7-4* Adv. Process PID Ctrl.

Parameter group 7-4* is only used if par. 1-00 Configuration

Mode is set to [7] Extended PID speed CL or [8] Extended PID

Speed OL.

7-40 Process PID I-part Reset

Option: Function:

[0]

*

No

[1] Yes Select Yes [1] to reset the I-part of the process PID

controller. The selection will automatically revert to No

[0]. Resetting the I-part makes it possible to start from a

well-defined point after changing something in the

process, e.g., changing a textile roll.

7-41 Process PID Output Neg. Clamp

Range: Function:

-100 %

*

[Application

dependant]

Enter a negative limit for the

process PID controller output.

7-42 Process PID Output Pos. Clamp

Range: Function:

100 %

*

[Application

dependant]

Enter a positive limit for the

process PID controller output.

7-43 Process PID Gain Scale at Min. Ref.

Range: Function:

100 %

*

[0 - 100

%]

Enter a scaling percentage to apply to the

process PID output when operating at the

minimum reference. The scaling percentage

will be adjusted linearly between the scale at

min. ref. (7-43 Process PID Gain Scale at Min.

Ref.) and the scale at max. ref. (7-44 Process

PID Gain Scale at Max. Ref.).

7-44 Process PID Gain Scale at Max. Ref.

Range: Function:

100 %

*

[0 - 100

%]

Enter a scaling percentage to apply to the

process PID output when operating at the

maximum reference. The scaling percentage

will be adjusted linearly between the scale at

min. ref. (7-43 Process PID Gain Scale at Min.

Ref.) and the scale at max. ref. (7-44 Process

PID Gain Scale at Max. Ref.).

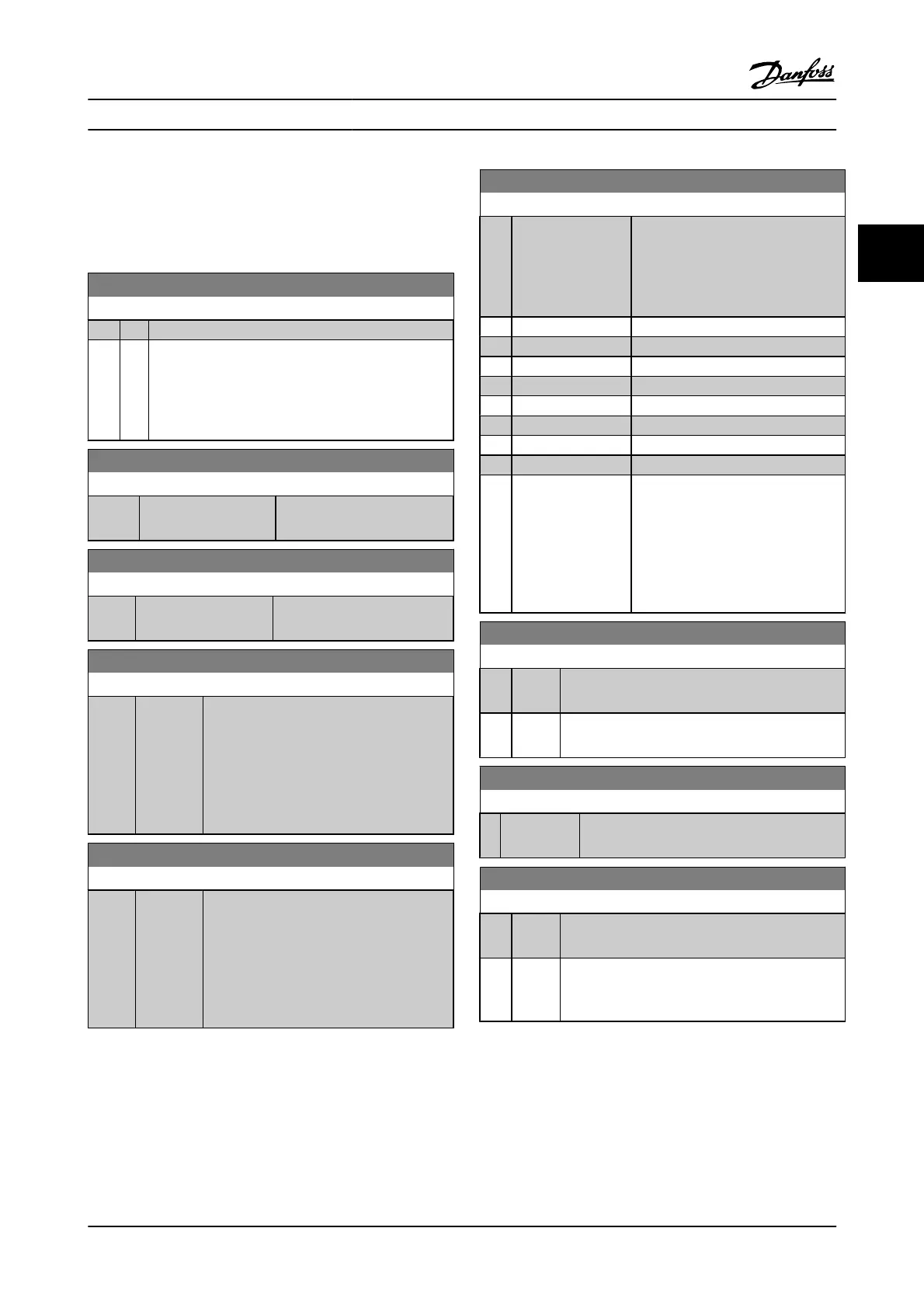

7-45 Process PID Feed Fwd Resource

Option: Function:

[0]

*

No function Select which drive input should be

used as the feed forward factor. The FF

factor is added directly to the output

of the PID controller. This increases

dynamic performance.

[1] Analog input 53

[2] Analog input 54

[7] Frequency input 29

[8] Frequency input 33

[11] Local bus reference

[20] Digital pot.meter

[21] Analog input X30-11

[22] Analog input X30-12

[32] Bus PCD Selects a bus reference configured by

Par. 8-02 Control Word Source. Change

PCD Write Configuration (8-42) for the

bus used in order to make the feed-

forward available in par. 7-48. Use

index 1 for feed-forward [748] (and

index 2 for reference [1682]).

7-46 Process PID Feed Fwd Normal/ Inv. Ctrl.

Option: Function:

[0]

*

Normal Select Normal [0] to set the feed forward factor to

treat the FF resource as a positive value.

[1] Inverse Select Inverse [1] to treat the FF resource as a

negative value.

7-48 PCD Feed Forward

Range: Function:

0

*

[0 - 65535 ] Readout parameter where the bus PCD feed

forward (par. 7-45 [32]) can be read.

7-49 Process PID Output Normal/ Inv. Ctrl.

Option: Function:

[0]

*

Normal Select Normal [0] to use the resulting output from

the process PID controller as is.

[1] Inverse Select Inverse [1] to invert the resulting output from

the process PID controller. This operation is

performed after the feed forward factor is applied.

Parameter Descriptions FC 300 Programming Guide

MG.33.MA.22 - VLT

®

is a registered Danfoss trademark 3-79

3

Loading...

Loading...