Application guidelines

17FRCC.PC.002.A4.22

System design recommendations

Suction line

Piping design

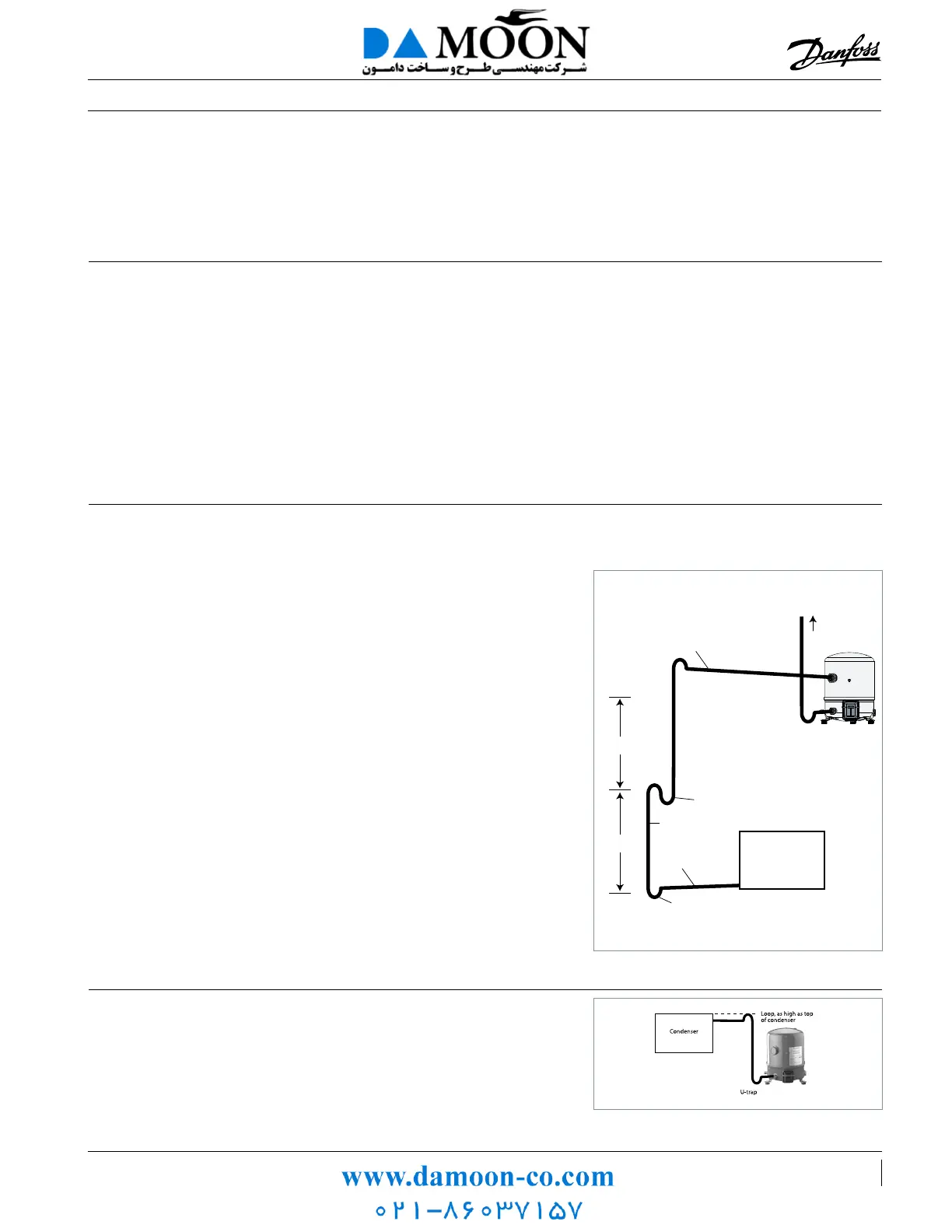

Horizontal suction line sections shall have a slope

of 0.5% in the direction of refrigerant ow (5/8”

per 10 ft of pipe).The cross-section of horizontal

suction lines shall be such that the resulting gas

velocity is at least 13 ft/s. In vertical risers, a gas

velocity of 26 to 40 ft/s is required to ensure

proper oil return.

A U-trap is required at the foot of each vertical

riser. If the riser is higher than 13 ft, additional

U-traps are required for each additional 13ft.

The length of each U-trap must be as short as

possible to avoid the accumulation of excessive

quantities of oil (see gure below).

Gas velocities higher than 40 ft/s will not con-

tribute to signicantly better oil return. However

they will cause higher noise levels and result in

higher suction line pressure drops which will

have a negative eect on the system capacity.

Note that the suction rotolock valves, which

can be ordered from Danfoss as accessories, are

designed for average pipe sizes, selected for

systems running at nominal conditions. The pipe

sizes selected for specic systems may dier from

these average sizes.

The suction line must always be insulated to limit

suction gas superheat.

Oil in a refrigeration circuit is required to lubricate

moving parts in the compressor. During nor-

mal system operation small oil quantities will

continuously leave the compressor, with the

discharge gas. Therefore, the system piping shall

be designed in a way which allows a good oil

circulation, avoiding oil being trapped in the

system and ensuring a constant oil return to the

compressor. As long as the amount of oil circulat-

ing through the system is small it will contribute

to good system operation and improved heat

transfer eciency.

Lubricant getting trapped in the evaporator or

suction lines will aect system performance and

will ultimately lead to compressor lubrication

failures. Where a poor oil return situation exists,

adding lubricant will not help safeguard the com-

pressor. Only a correct piping design can ensure

adequate oil circulation maintaining safe oil level

in the compressor.

Maneurop® NTZ compressors have been de-

signed and qualied for stationary equipment

using standard alternating power supply. Danfoss

does not warrant the compressors for use on

mobile applications such as trucks, railways,

subways, ships etc.

These selection and application guidelines con-

cern single compressors only. For guidelines on

manifolding Maneurop® NTZ compressors, please

refer to literature called "Parallel Application

Guidelines".

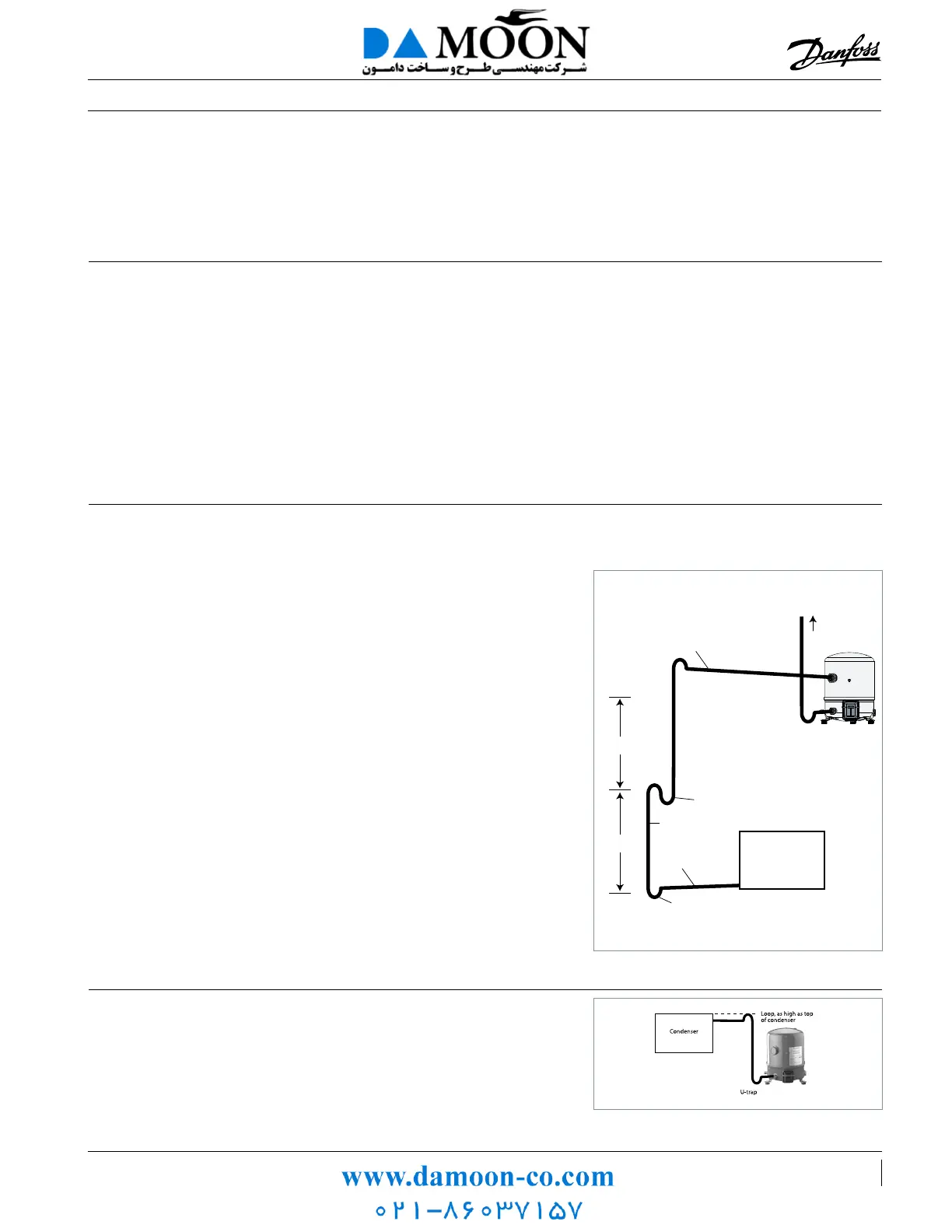

Discharge line When the condenser is mounted above the

compressor, a loop above the condenser and a

U-trap close to the compressor are required to

prevent liquid draining from the condenser into

the discharge line during standstill.

0.5 % slope,

13 ft/s or more

0.5 % slope,

13 ft/s or more

To condenser

max. 13 ft

max. 13 ft

26 to 40 ft/s

U-trap, as short as possible

U-trap, as short as possible

U-trap

Evaporator

Loading...

Loading...