105 of 114M-AP-001-EN Rev. Q

20.6.3 Voltage-Free Contacts

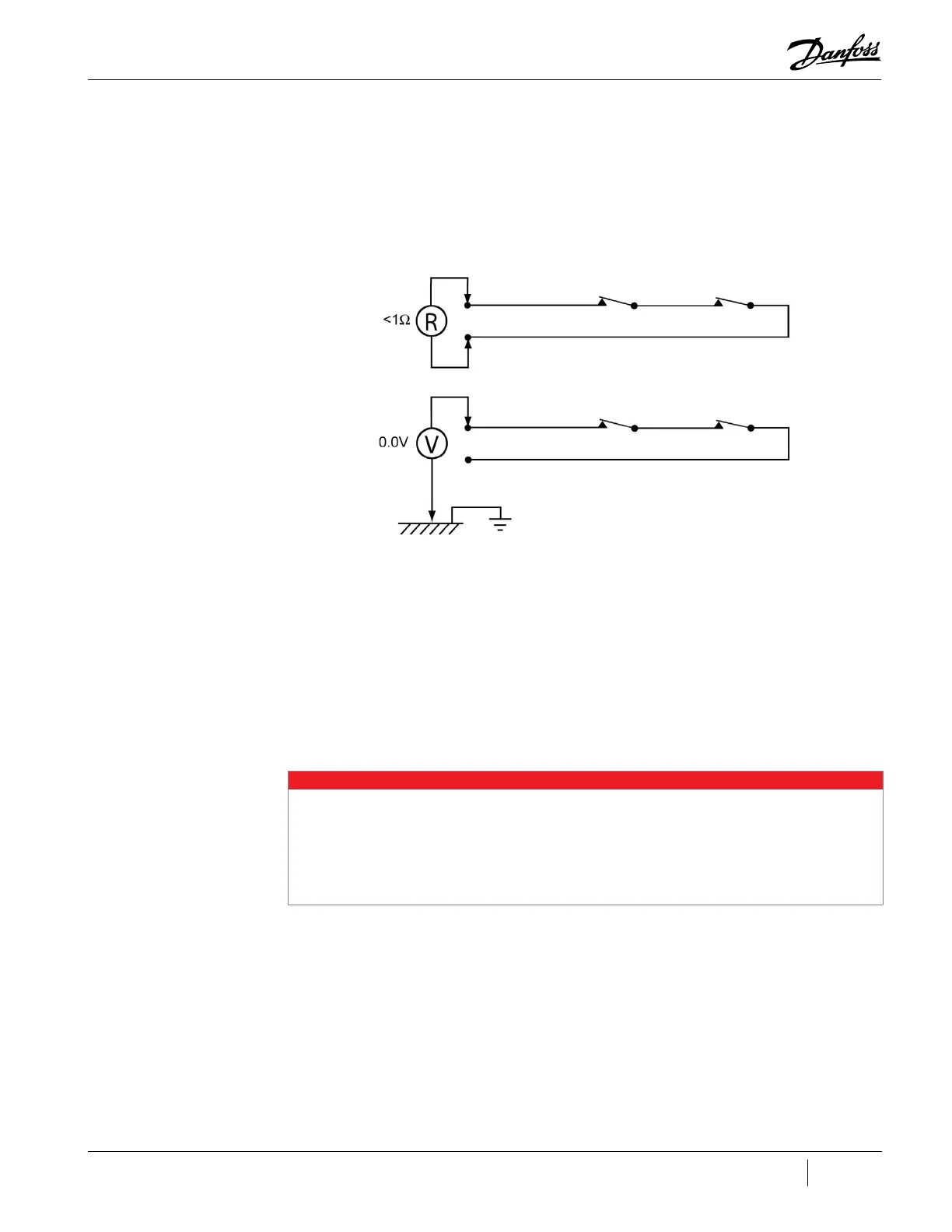

Prior to connecting the interlock terminals of the compressor I/O board, measure the resistance

across the customer’s interlock terminals (refer to "Figure 20-8 Interlock Circuit Tests"). Ensure that the

interlock contacts are closed. The measured value should be less than 1Ω.

Figure 20-8 Interlock Circuit Tests

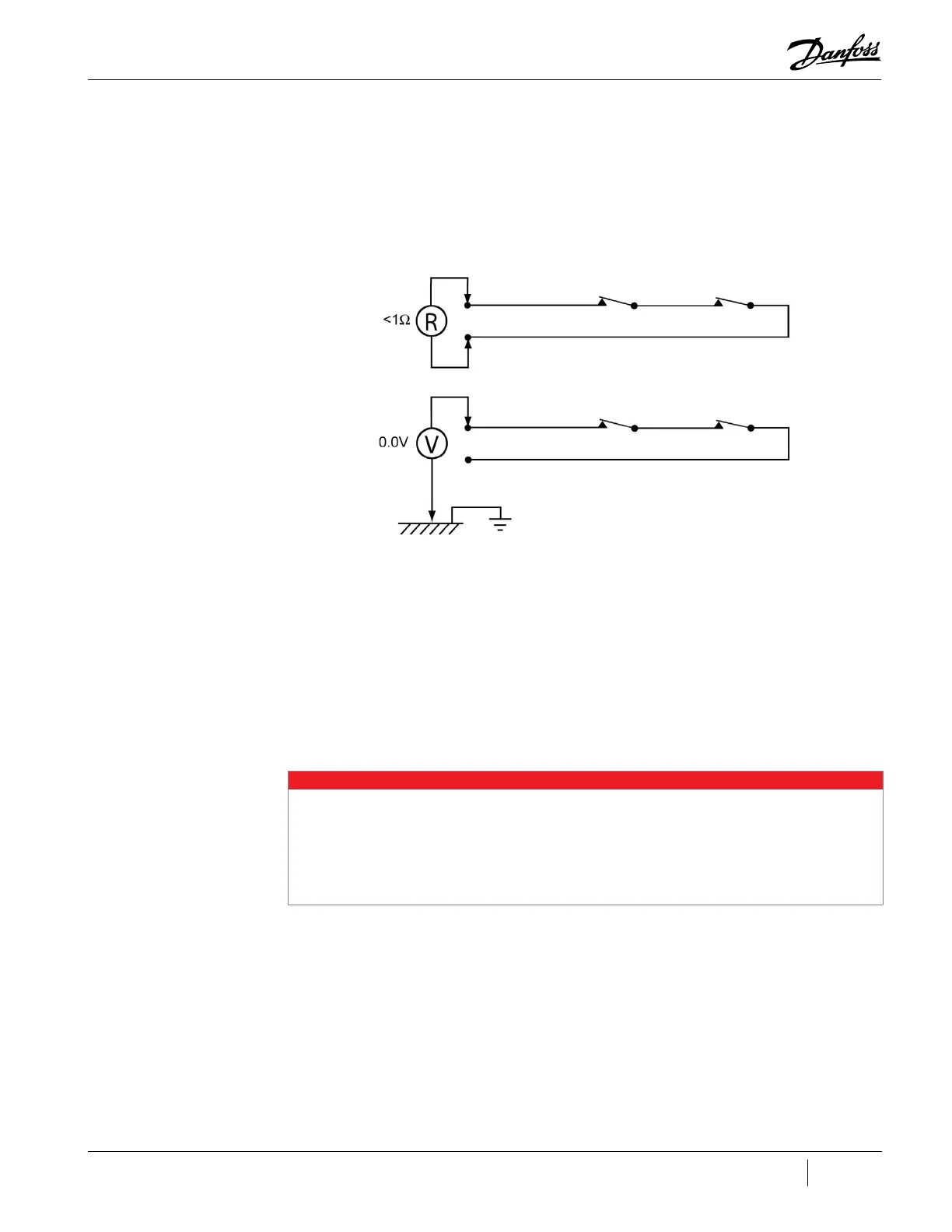

Measure the voltage between each customer interlock terminal and the frame ground while the

interlock contacts are open and closed. In either contact state, if the measured voltage is not zero

(0), verify the source of the voltage. Do not connect the interlock terminals until the voltage source is

removed (refer to "Figure 20-9 Typical Electrical Connections" on page 106).

20.7 Power Wiring

This section describes the connection of the power wiring to the compressor.

"Figure 20-9 Typical Electrical Connections" on page 106 shows a typical schematic for the

compressor’s electrical connections.

I/Lock

I/Lock

Interlock Circuit

Interlock Circuit

NOTE

The AC input cable should be CSA, UL, or CE approved, 3-wire with a common shield and single ground. It is recommended that

the cable be double-jacketed; for example, a teck cable type. The cable must be rated for 90° C (194° F) minimum with a

maximum current rating corresponding to the LRA value on the compressor nameplate.

Keep power cables and control interface cables in separate conduits. Use metal cable glands for shielded cables to ensure good

grounding.

If you are installing a Danfoss LLC line reactor or EMI or harmonic filter in the mains input circuit, refer to the applicable

installation instructions.

Loading...

Loading...