14

VLT is a registered Danfoss trademark

Shield

Net -

Net +

ARC156 Network

Port 1

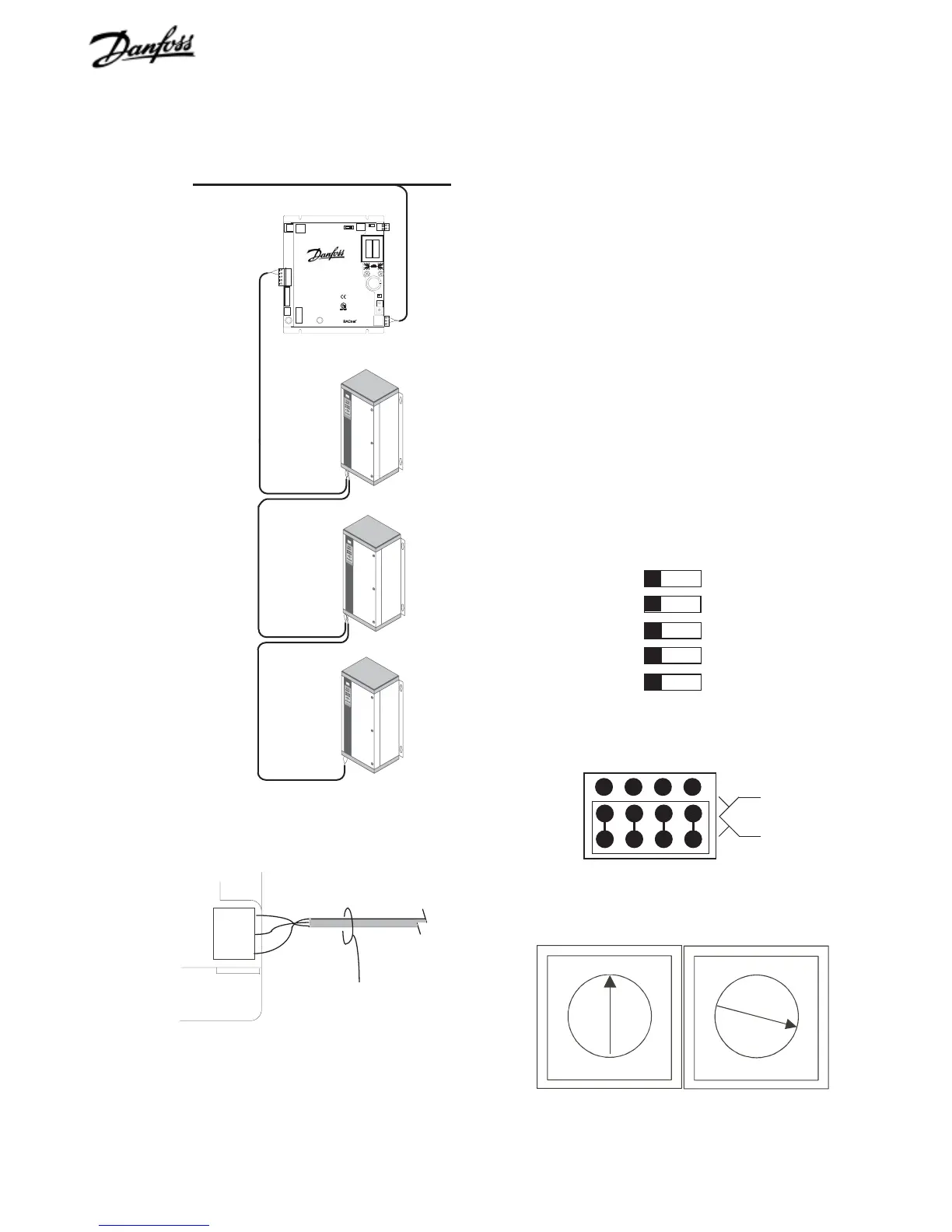

ARCnet network connection

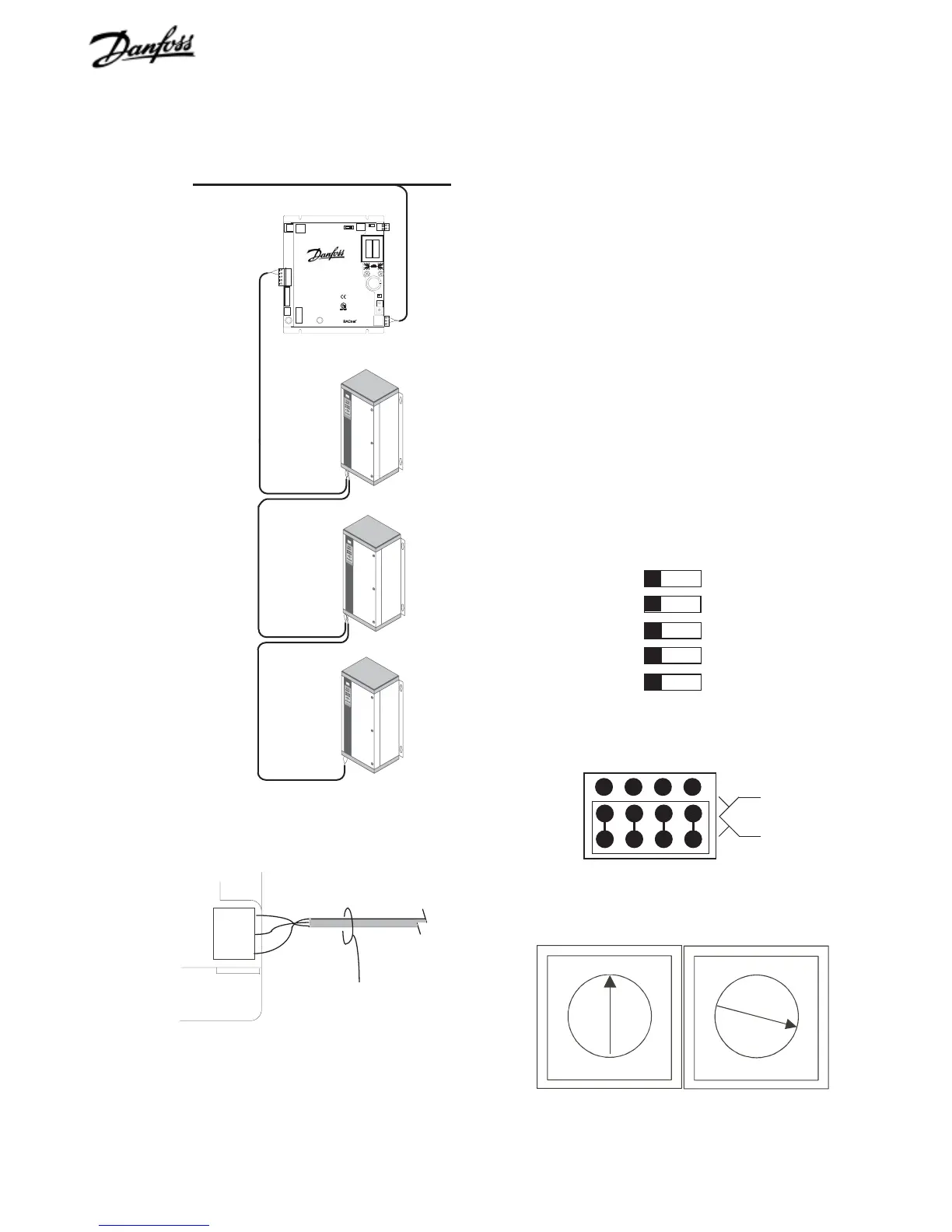

Figure 13. Port 2 Configuration Jumper Settings

Figure 11. ARCnet Network Connection

Figure 12. BACLink DIP Switches

Procedure

1. Switch BACLink portal power off.

2. Wire ARCnet network input cable to BACLink port1 (see

Figure 11).

3. Set port 1 DIP switch to ARC156 (see Figure 12).

4. Plug EIA-485/232 configuration jumper to EIA-485 position

as shown in Figure 13.

5. Set portal device instance number using rotary address

switches (see Figure 14).

6. Set BACLink portal address DIP switch. BACLink portal

DIP switch 5 (refer back to Figure 1) must correspond to

device instance number setting. Set switch to +0 for

addresses 0to 99 or to +100 for addresses 100 to199.

7. Wire to drives from BACLink port 2 from Net (+) to drive

terminal 68 and Net (-) to drive terminal 69.

1

2

3

4

IP Address

Switch 2

Port 1

Off/ On

Default/ Assigned

Portal Address

+0/+100

ARC156/ Other

Off/On

5

Switch 1

EIA-485

EIA-232

ARCnet

VLT

®

BACLink

™

ARCnet

EIA-485

NOTE: EIA-485 Net+

and Net- from Port 2

to drive input terminals

68 (+) and 69 (-)

NOTE: Terminate shield at only

one portal of a multiportal

network.

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10's digit

1's digit

Figure 14. Rotary Address Switches

Loading...

Loading...