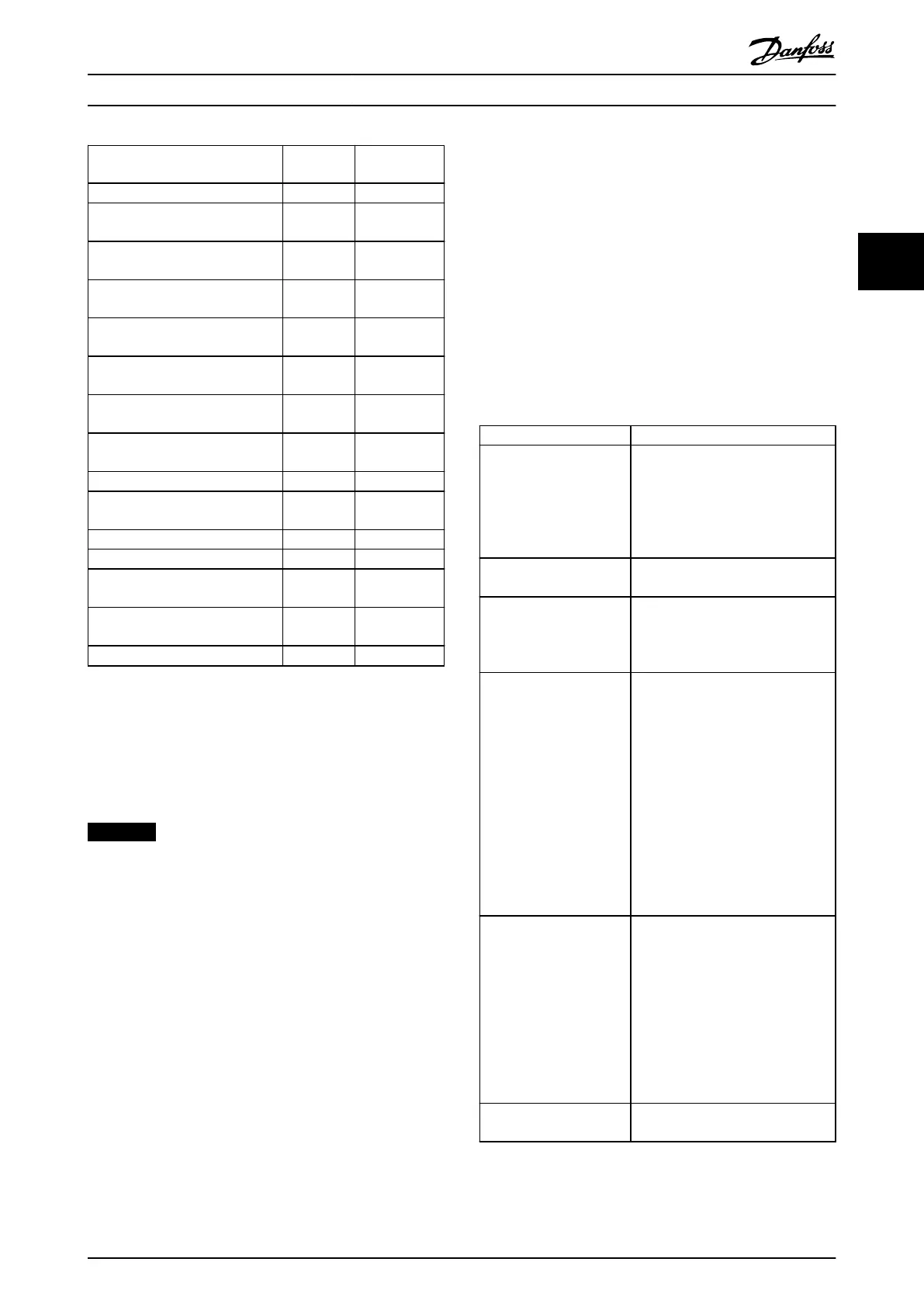

Parameter 1-10 Motor

Construction

[0]

Asynchron

[1] PM Motor

non salient

Parameter 2-17 Over-voltage Control

x

Parameter 4-10 Motor Speed

Direction

x x

Parameter 4-11 Motor Speed Low

Limit [RPM]

x x

Parameter 4-12 Motor Speed Low

Limit [Hz]

x x

Parameter 4-13 Motor Speed High

Limit [RPM]

x x

Parameter 4-14 Motor Speed High

Limit [Hz]

x x

Parameter 4-16 Torque Limit Motor

Mode

x x

Parameter 4-17 Torque Limit

Generator Mode

x x

Parameter 4-18 Current Limit

x x

Parameter 4-19 Max Output

Frequency

x x

4-58 Missing Motor Phase Function

x

Parameter 14-40 VT Level

x

Parameter 14-41 AEO Minimum

Magnetisation

x

Parameter 14-42 Minimum AEO

Frequency

x

Parameter 14-43 Motor Cosphi

x

Table 3.4 Motor Selection Parameter

3.3.3

SynRM Motor Set-up with VVC

+

This section describes how to set up a SynRM motor with

VVC

+

.

NOTICE

The SmartStart wizard covers the basic conguration of

SynRM motors.

Initial programming steps

To activate SynRM motor operation, select [5] Sync.

Reluctance in 1-10 Motor Construction.

Programming motor data

After performing the initial programming steps, the SynRM

motor-related parameters in parameter groups 1-2* Motor

Data, 1-3* Adv. Motor Data, and 1-4* Adv. Motor Data II are

active. Use the motor nameplate data and the motor

datasheet to programme the following parameters in the

order listed:

•

1-23 Motor Frequency.

•

1-24 Motor Current.

•

1-25 Motor Nominal Speed.

•

1-26 Motor Cont. Rated Torque.

Run a complete AMA using

1-29 Automatic Motor

Adaptation (AMA) [1] Enable Complete AMA or enter the

following parameters manually:

•

1-30 Stator Resistance (Rs).

•

1-37 d-axis Inductance (Ld).

•

1-44 d-axis Inductance Sat. (LdSat).

•

1-45 q-axis Inductance Sat. (LqSat).

•

1-48 Inductance Sat. Point.

Application-specic adjustments

Start the motor at nominal speed. If the application does

not run well, check the VVC

+

SynRM settings. Table 3.5

provides application-specic recommendations:

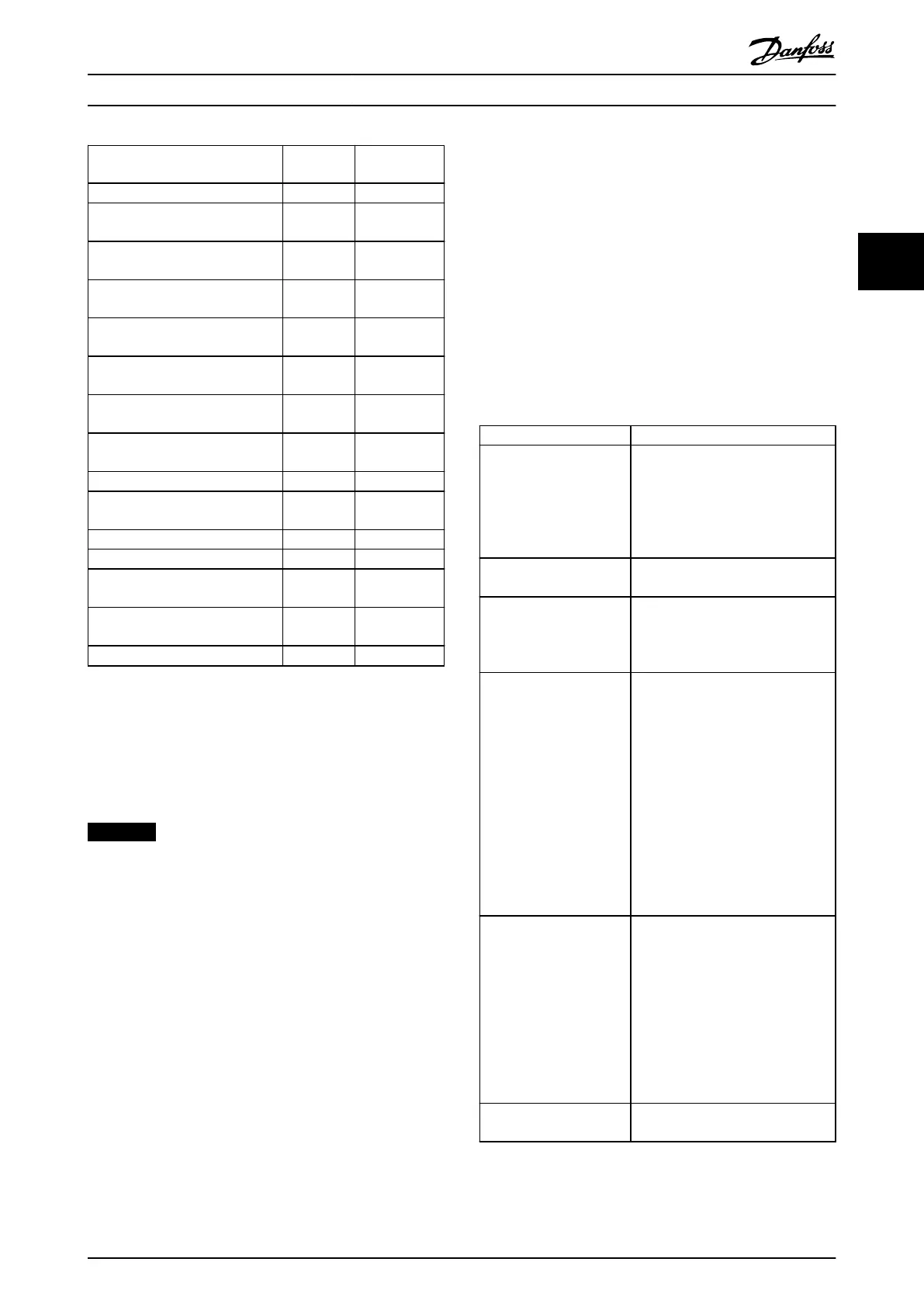

Application Settings

Low-inertia applications

I

Load

/I

Motor

<5

Increase parameter 1-17 Voltage lter

time const. by factor 5 to 10.

Reduce parameter 1-14 Damping

Gain.

Reduce parameter 1-66 Min. Current

at Low Speed (<100%).

Low-inertia applications

50>I

Load

/I

Motor

>5

Keep the default values.

High-inertia applications

I

Load

/I

Motor

> 50

Increase parameter 1-14 Damping

Gain, 1-15 Low Speed Filter Time

Const., and 1-16 High Speed Filter

Time Const.

High-load at low speed

<30% (rated speed)

Increase parameter 1-17 Voltage lter

time const.

Increase parameter 1-66 Min. Current

at Low Speed to adjust the starting

torque. 100% current provides

nominal torque as starting torque.

This parameter is independent of

30-20 High Starting Torque Time [s]

and 30-21 High Starting Torque

Current [%]). Working at a current

level higher than 100% for a

prolonged time can cause the motor

to overheat.

Dynamic applications

Increase 14-41 AEO Minimum

Magnetisation for highly dynamic

applications. Adjusting 14-41 AEO

Minimum Magnetisation ensures a

good balance between energy

eciency and dynamics. Adjust

14-42 Minimum AEO Frequency to

specify the minimum frequency at

which the frequency converter

should use minimum magnetisation.

Motor sizes less than 18

kW

Avoid short ramp-down times.

Table 3.5 Recommendations for Various Applications

If the motor starts oscillating at a certain speed, increase

1-14 Damping Gain. Increase the damping gain value in

Parameter Descriptions

Programming Guide

MG11CE02 Danfoss A/S © 03/2015 All rights reserved. 39

3 3

Loading...

Loading...