[4] AC brake Monitors for a short-circuit or disconnection of the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the adjustable frequency drive performs a controlled ramp-down. This option

is available for FC 302 only.

[5] Trip Lock

NOTE!

Remove a warning arising in connection with

Off

[0] or

Warning

[1] by cycling the line power supply. The fault must be corrected first.

For

Off

[0] or

Warning

[1], the adjustable frequency drive keeps running even if a fault is located.

This parameter is only active in adjustable frequency drives with an integral dynamic brake.

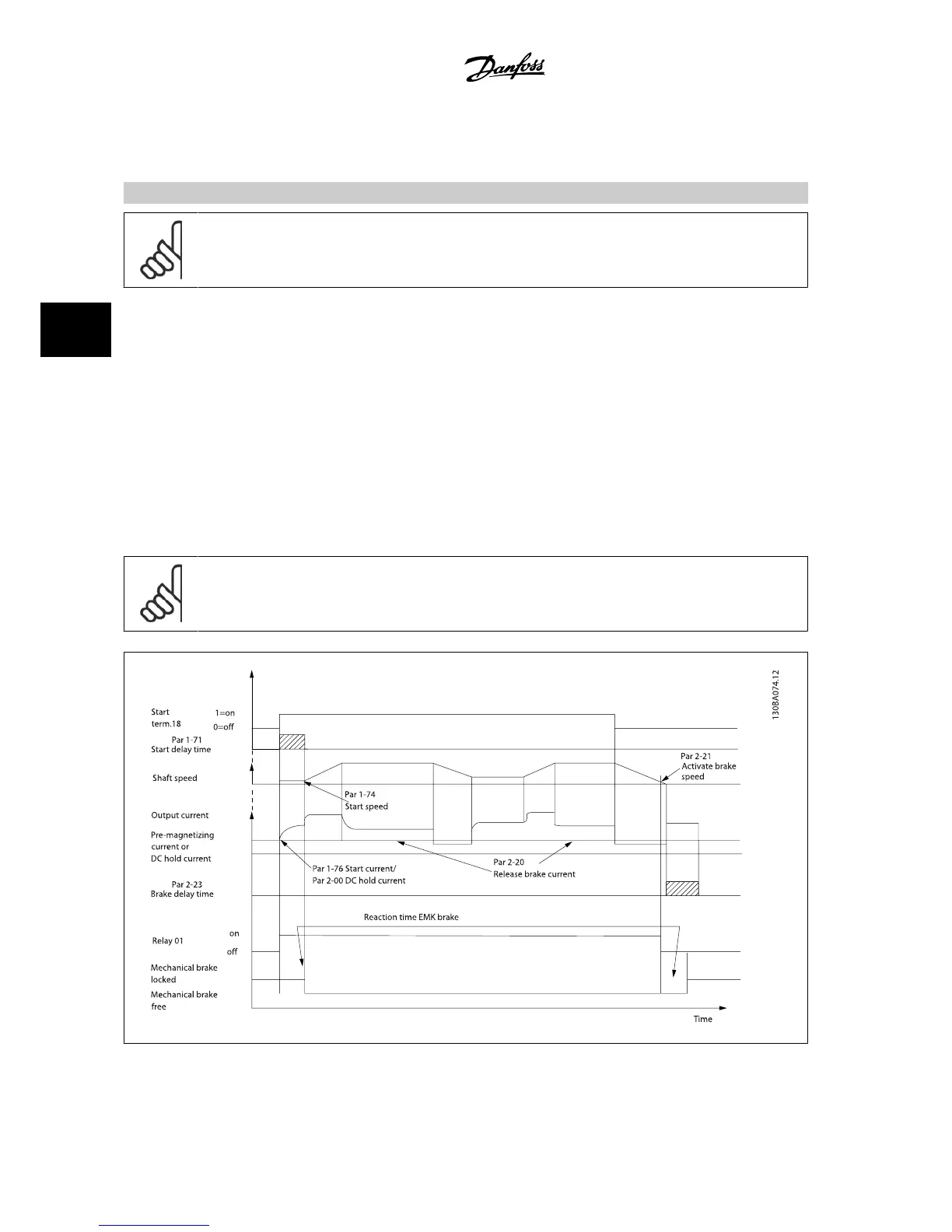

4.3.1 2-2* Mechanical Brake

Parameters for controlling operation of an electro-magnetic (mechanical) brake, typically required in hoisting applications.

To control a mechanical brake, a relay output (relay 01 or relay 02) or a programmed digital output (terminal 27 or 29) is required. Normally, this output

must be closed during periods when the adjustable frequency drive is unable to ‘hold’ the motor, e.g., due to an excessive load. Select

Mechanical Brake

Control

[32] for applications with an electro-magnetic brake in par. 5-40

Function Relay

, par. 5-30

Terminal 27 Digital Output

, or par. 5-31

Terminal 29

digital Output

. When selecting

Mechanical brake control

[32], the mechanical brake is closed from start up until the output current is above the level

selected in par. 2-20

Release Brake Current

. During stop, the mechanical brake activates when the speed falls below the level specified in par. 2-21

Activate

Brake Speed [RPM]

. If the adjustable frequency drive enters an alarm condition or an overcurrent or overvoltage situation, the mechanical brake imme-

diately cuts in. This is also the case during safe stop.

NOTE!

Protection mode and trip delay features (par. 14-25

Trip Delay at Torque Limit

and par. 14-26

Trip Delay at Inverter Fault

) may delay

the activation of the mechanical brake in an alarm condition. These features must be disabled in hoisting applications.

4 How to Program

VLT

®

AutomationDrive FC 300 Instruction

Manual

4-12

MG.33.AG.22 - VLT

®

is a registered Danfoss trademark

4

Loading...

Loading...