Figure 3.25 Control Cable Connection

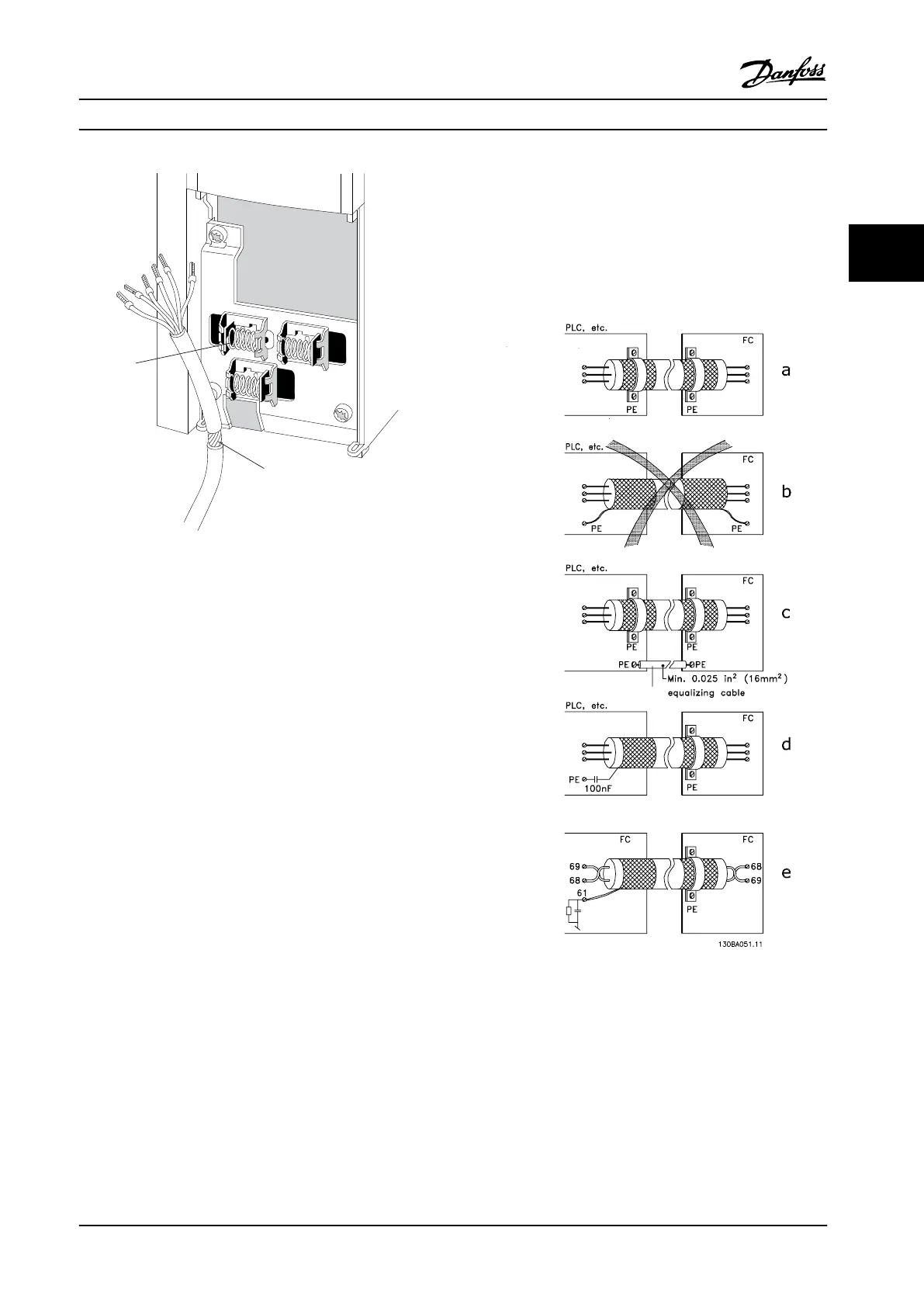

Figure 3.26 indicates how correct grounding is carried out

and what to do if in doubt.

a. Correct grounding

Control cables and cables for serial communication must

be

tted with cable clamps at both ends to ensure the

best possible electrical contact.

b. Wrong grounding

Do not use twisted cable ends (pigtails). They increase the

screen impedance at high frequencies.

c. Protection concerning ground potential between PLC

(Program Logic Controller) and frequency converter

If the ground potential between the frequency converter

and the PLC (etc.) is dierent, electric noise may occur that

disturbs the entire system. Solve this problem by tting an

equalizing cable, next to the control cable. Minimum cable

cross-section: 16 mm

2

.

d. For 50/60 Hz ground loops

If long control cables are used, 50/60 Hz ground loops may

occur. Solve this problem by connecting one end of the

screen to ground via a 100 nF capacitor (keeping leads

short).

e. Cables for serial communication

Eliminate low-frequency noise currents between two

frequency converters by connecting one end of the screen

to terminal 61. This terminal is connected to ground via an

internal RC link. To reduce the dierential mode

interference between the conductors, use twisted-pair

cables.

Figure 3.26 Examples of ground Wiring

How to Install Operating Instructions

MG34M422 Danfoss A/S © Rev. 2013-07-03 All rights reserved. 25

3 3

Loading...

Loading...