7 Packet Structures

7.1 Ensuring Safe and Successful Control

Data written to the EtherNet/IP Module remains in its

register until the data is overwritten or the module is

reinitialized. The EtherNet/IP Module does not transfer

successive duplicate commands to the soft starter.

•

If the soft starter is started via

eldbus communi-

cation but stopped via the LCP or a remote input,

an identical start command cannot be used to

restart the soft starter.

•

If the soft starter is controlled via the LCP or the

remote inputs (and via eldbus communications),

a control command should be immediately

followed by a status query to conrm that the

command has been actioned.

NOTICE

Functions available only in VLT

®

Soft Starter MCD 500:

•

Parameter management

•

Dual motor control

•

Digital inputs

•

Jog

•

Current measurement in amperes

•

Power information

•

Warnings

NOTICE

VLT

®

Compact Starter MCD 201 open-loop soft starters

do not support motor current and motor temperature

information.

7.2 Cyclic Operation

This section lists requirements related to cyclic services for

the EtherNet/IP Module. The EtherNet/IP Module uses both

implicit (I/O) and explicit messaging, with a cyclic trigger

(minimum cyclic interval = 1 ms).

7.2.1 Assembly Objects

The EtherNet/IP Module supports the assembly objects

listed in Table 7.1.

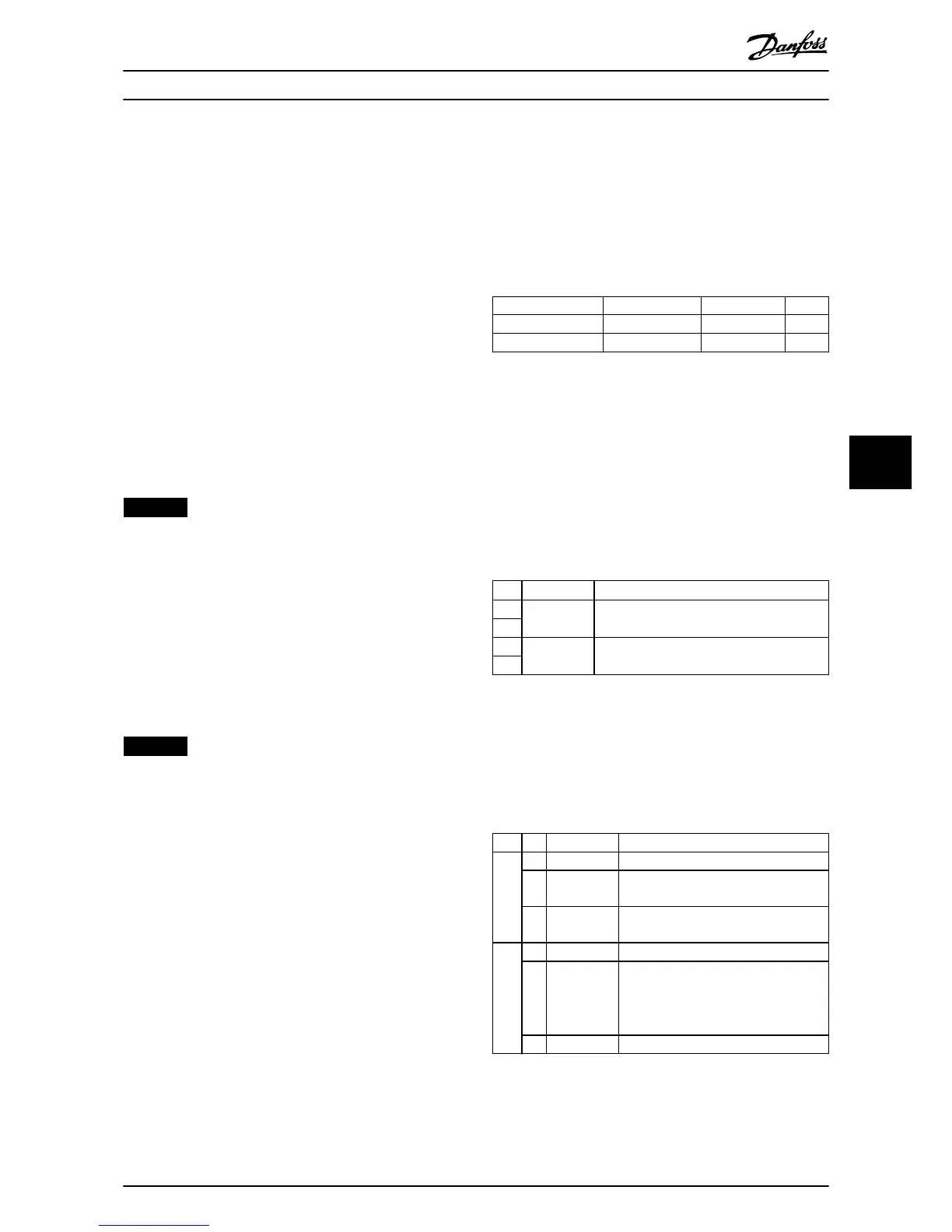

Assembly instances Description Maximum size Type

104

Originator⇒target

2 (4) bytes Integer

154

Target⇒originator

6 (12) bytes Integer

Table 7.1 Assembly Objects

7.2.2 Control Commands

7.2.2.1 Receiving Control Data from the

Controller

The EtherNet/IP Module uses output assembly instance

104d in assembly class 0x04 to receive control data from

the controller. This instance is the only valid assembly

instance.

Byte

Function

1)

Details

0 Control word See chapter 7.2.2.2 Control Word (Write-only)

for details.

1

2 Reserved Must be 0.

3

Table 7.2 Valid Assembly Instance

1) All elds are in little-endian format.

7.2.2.2 Control Word (Write-only)

Use the structure in Table 7.3 to send a control command

to the soft starter.

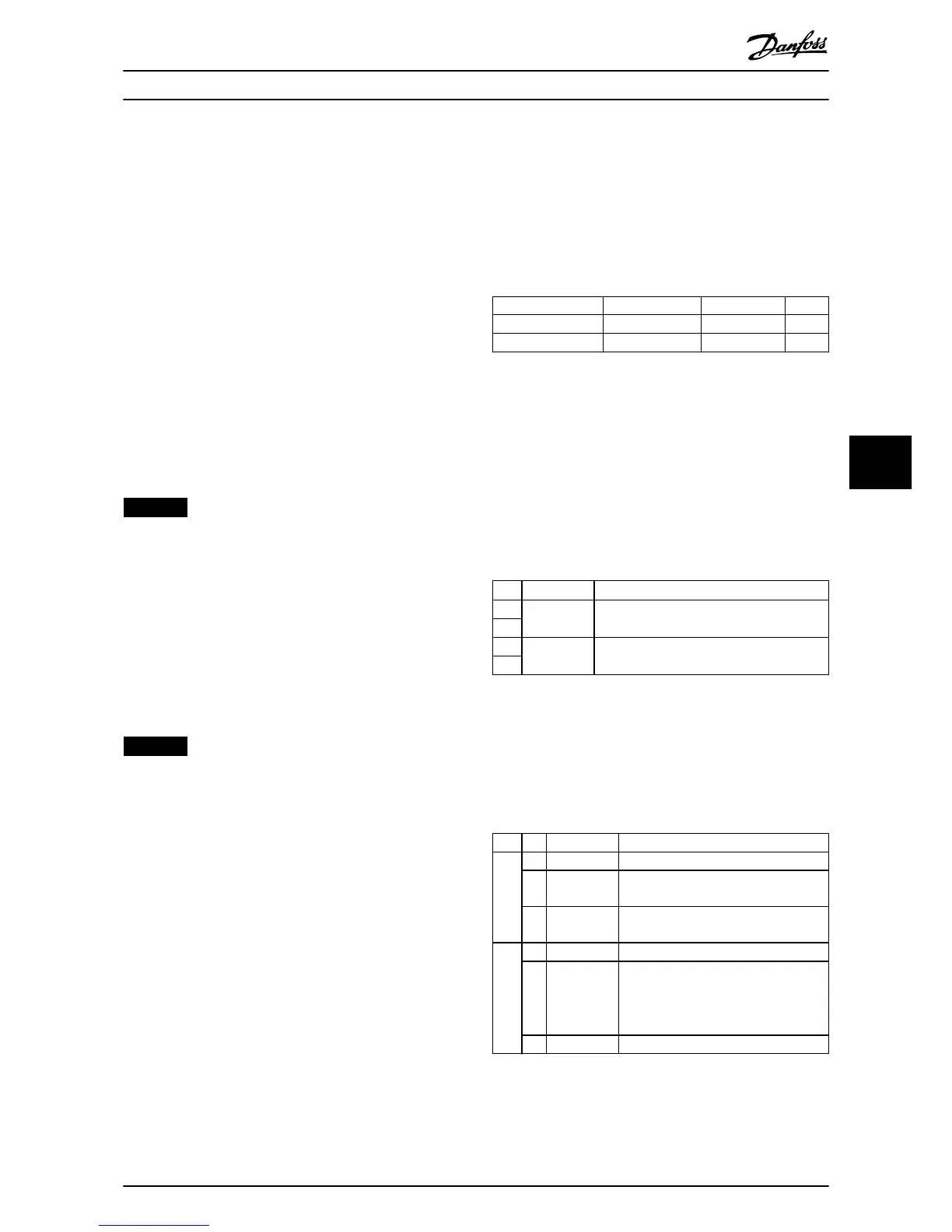

Byte Bit Function

0

0–5 Reserved Must be 0.

6 Run 0 = Stop command

1 = Start command

7 Reset Changing this bit from 0 to 1 resets a

trip.

1

0–4 Reserved Must be 0.

5 Motor set

select

0 = Use primary motor set when

starting

1)

1 = Use secondary motor set when

starting

1)

6–7 Reserved Must be 0.

Table 7.3 Control Word Structure

1) Ensure that the programmable input is not set to motor set select

before using this function.

Packet Structures Installation Guide

MG17Q102 Danfoss A/S © 05/2017 All rights reserved. 13

7 7

Loading...

Loading...