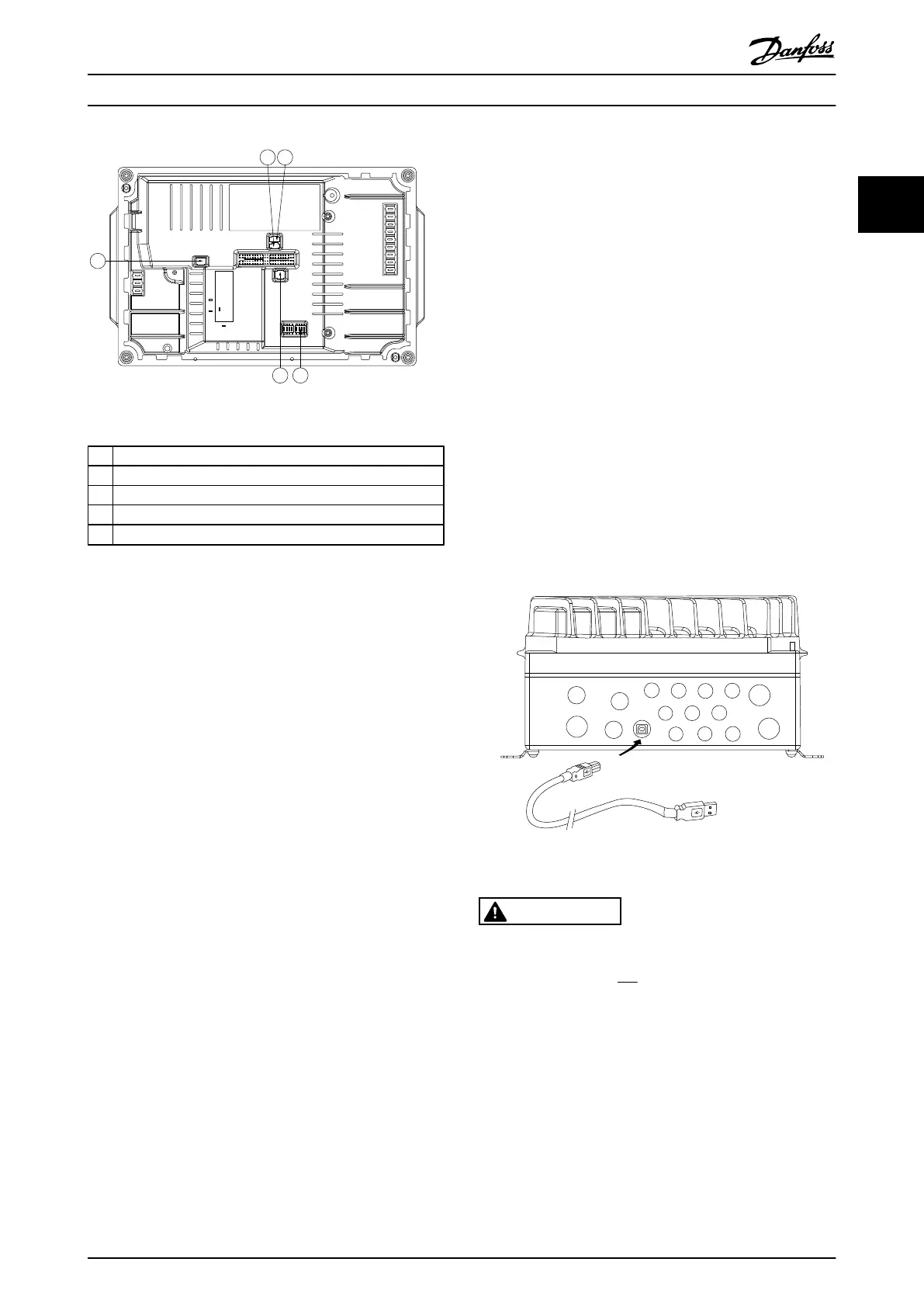

Illustration 2.19 Location of DIP Switches

1 S201 - terminal 53

2 S202 - terminal 54

3 S801 - standard bus termination

4 Profibus termination

5 Fieldbus address

NOTE

Switches 4 and 5

are only valid for units fitted with

fieldbus options.

2.4.14 Serial Communication

Connect RS-485 serial communication wiring to terminals

(+)68 and (-)69.

•

Switch S801

(BUS TER.) can be used to enable

termination on the RS-485 port (terminals 68 and

69). See Illustration 2.19.

•

Shielded serial communication cable is

recommended

•

See 2.4.11 Earth (Grounding) Requirements for

proper grounding

•

Two communication protocols are internal to the

frequency converter

•

Danfoss FC

•

Modbus RTU

•

For basic serial communication setup, select the

following

•

Protocol type in 8-30 Protocol

•

Frequency converter address in

8-31 Address

•

Baud rate in 8-32 FC Port Baud Rate

•

Functions can be programmed remotely using

the protocol software and RS-485 connection or

in parameter group 8-** Communications and

Options

•

Selecting

a specific communication

protocol

changes various default parameter settings to

match that specifications of the protocol along

with making additional protocol-specific

parameters available

•

Control card options are available to provide

additional communication protocols. See the

option-card documentation for installation and

operation instructions

•

Profibus

•

Ethernet IP

•

ProfiNet

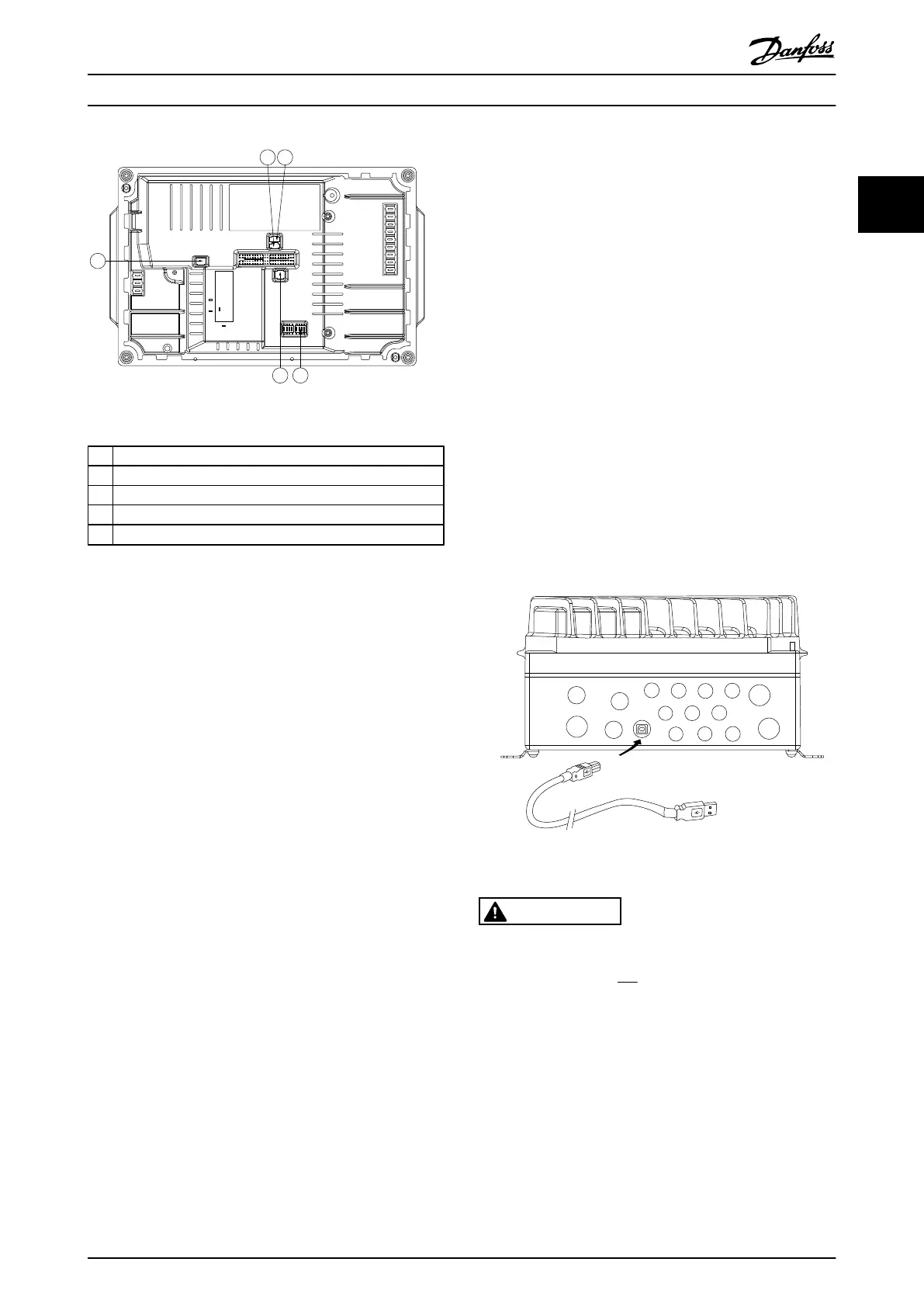

2.4.15 Connection to PC

To control the frequency converter from a PC, install the

MCT

10 Set-up Software.

The

PC is connected via a standard (host/device) USB

cable, or via the RS-485 interface.

Illustration 2.20 Electronic Part

CAUTION

The USB connection is galvanically isolated from the

supply voltage (PELV) and

other high-voltage terminals.

The USB connection is

not galvanically isolated from

protection earth. Use only

isolated laptop/PC as connection

to the USB connector on frequency converter or an

isolated USB cable/converter.

2.4.16 Safe Stop

The FCD 302 provides safe stop functionality via control

terminal

37.

Safe

stop

disables the control voltage of the

power semiconductors of the frequency controller output

stage. This in turn prevents generating the voltage

required to rotate the motor. When the Safe Stop (T37) is

Installation

VLT

®

Decentral Drive FCD 302 Operating Instructions

MG04F302 - VLT

®

is a registered Danfoss trademark

25

2 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...