G – Piping Connection

INM.XX.X.00 G-7 April, 2018

Other Piping Systems and Special Cases

Space Heating and Space Cooling Hydronic Systems

Requirements, outlined in Piping Connection General Considerations (see above), apply to all types of space heating

and/or space cooling fluid systems (water, glycol, etc.) – refer to respective piping termination labels (IN/OUT), main

label (for line sizing) etc.

ATTENTION! If steam space heating coil is used – follow respective Code(s) recommendations, field practices

and steam coil and associated equipment (valves etc.) manufacturer’s guidance.

Gas-fired Space Heaters (duct gas heater, gas boiler, etc.)

Follow respective gas heater manufacturer requirements, as well as respective local codes, when piping and

connecting gas line to the heater (pipe sizing, supplied gas pressure, etc.). Refer to heater or dehumidifier

labels and stickers to locate gas connection.

Indoor-installed gas heater (boiler, duct heater, etc.) must be equipped with flue gas venting system – consult

gas heater manufacturer for proper venting system selection.

o Gas heater, packaged with the outdoor dehumidifier, normally would have provision for flue gas

venting, however in some cases (strong wind influences, location specifics, etc.) additional venting

system may be also required – consult gas heater manufacturer for proper type selection.

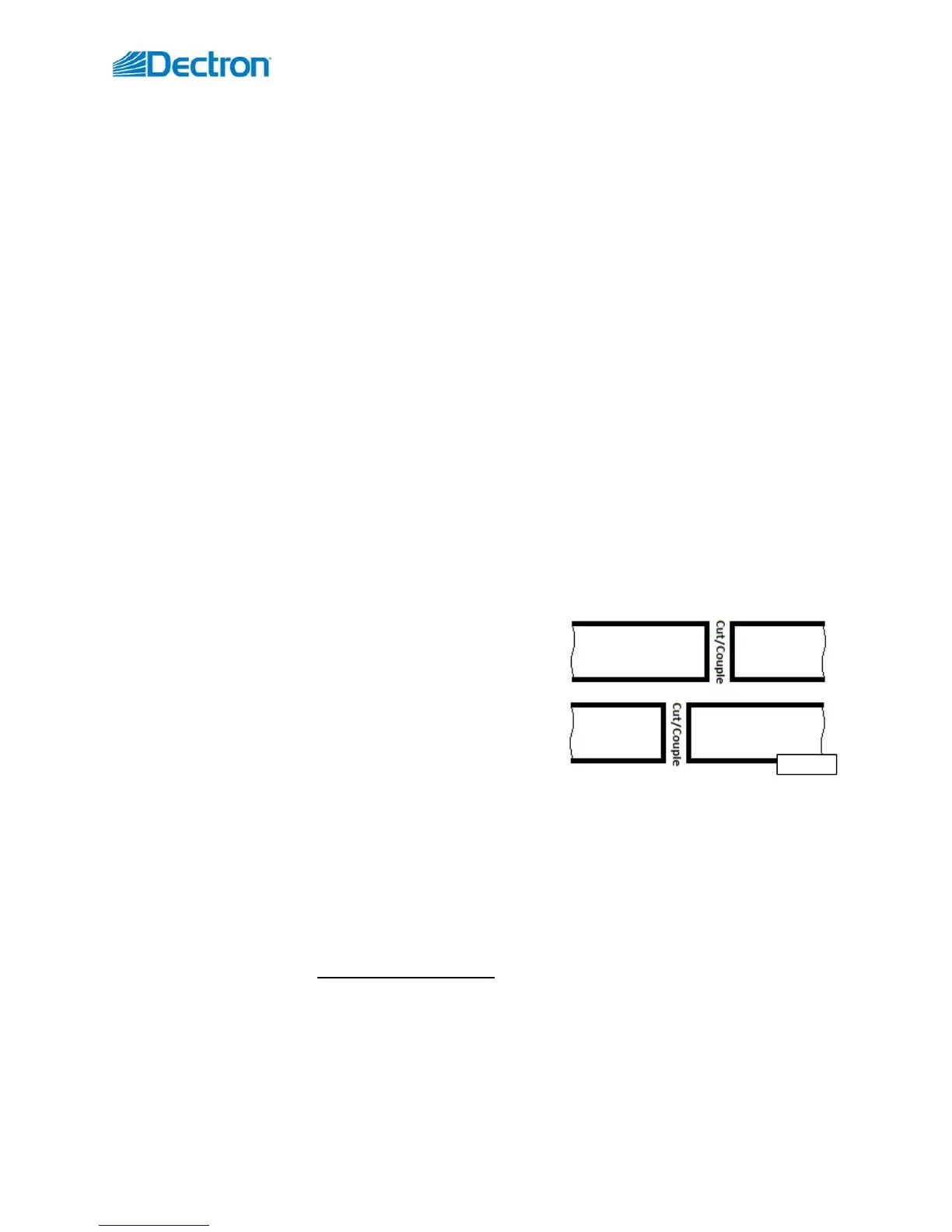

“Split-Cut” dehumidifier - piping assembly

When dehumidifier is provided from the factory in sections, field-assembly is required, including dehumidifier

internal piping reassembly.

Normally, such dehumidifiers are accompanied with Disassembly and Assembly Instructions – refer as needed.

Remove cups/plugs and join pipes respectively.

o To facilitate reassembly and avoid ambiguity, closely

located pipes are cut at the factory in “checkered”

pattern (see Pic. G.5) – once dehumidifier sections are

aligned properly, respective pipes would align too.

o Follow standard field practices, applicable to respective

pipe material/type and joining methods; ensure that

pipes and couplers are properly cleaned, sanded,

reamed, etc. as applicable. Normally, respective couplers are provided with the dehumidifier.

Pressure test/test for leaks re-joined piping and charge/upcharge re-joined circuit with respective fluid.

o Refer to dehumidifier submittal documentation and main label for respective circuits operating

pressure and media (water/glycol type and mixture ratio, type of refrigerant, etc.).

Follow proper field practices working with refrigeration circuits (brazing with nitrogen,

vacuuming, etc.); refer to recommendations in Outdoor Condenser Piping (see above).

o Depending on various circumstances, split-cut dehumidifier could be shipped with piping circuits

completely empty or partially charged – verify fluid presence in the circuit prior.

Normally, water and/or glycol circuits are provided empty – once joined, circuit must be

charged fully. Refer to Fluid Cooler Piping recommendations for charging.

Fill/upcharge water/glycol at the bottom of the system, bleed the air from ALL top

bleeding valves (manual and automatic). Ensure all air is bled out. Upcharge, if

needed, to achieve min 20-30 psi static pressure at the bottom of circuit.

Pic.G.5

Loading...

Loading...