PMAC-PCI Hardware Reference

PMAC-PCI E-Point Jumper Descriptions 15

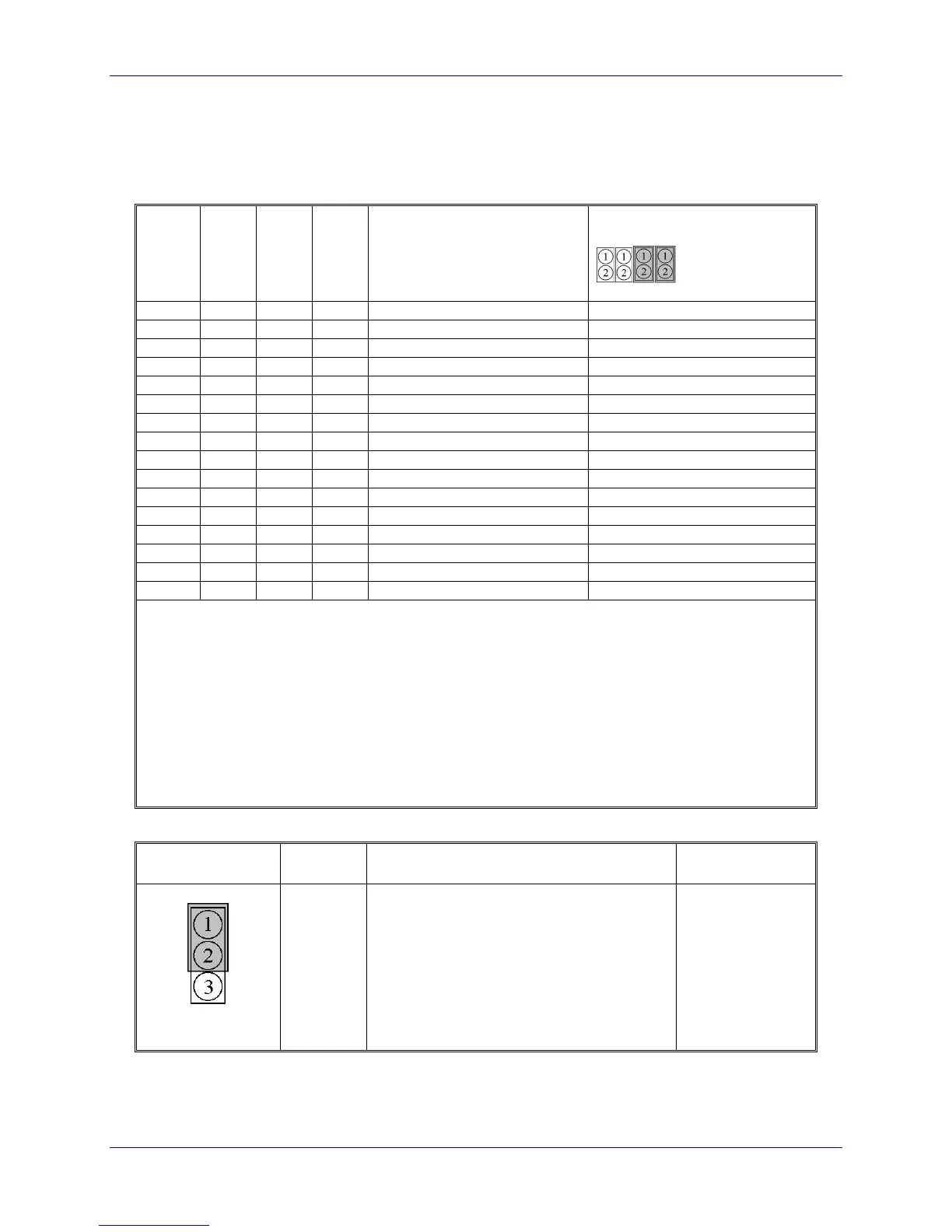

E3 - E6: Servo Clock Frequency Control

The servo clock (which determines how often the servo loop is closed) is derived from the phase clock

(see E98, E29 - E33) through a divide-by-N counter. Jumpers E3 through E6 control this dividing

function.

Servo Clock = Phase Clock

Divided by N

Default and Physical Layout

E3 E4 E5 E6

Location A4 A4 A4 A4

Note: The setting of I-variable I10 should be adjusted to match the servo interrupt cycle time set by E98,

E3 -- E6, E29 -- E33, and the crystal clock frequency. I10 holds the length of a servo interrupt cycle,

scaled so that 8,388,608 equals one millisecond. Since I10 has a maximum value of 8,388,607, the servo

interrupt cycle time should always be less than a millisecond (unless you want to make your basic unit of

time on PMAC something other than a millisecond). If you wish a servo sample time greater than one

millisecond, the sampling may be slowed in software with variable Ix60.

Frequency can be checked on J4 pins 21 & 22. It can also be checked from software by typing RX:0 in

the PMAC terminal at 10-second intervals and dividing the difference of successive responses by 10000.

The resulting number is the approximate Servo Clock frequency kHz.

Note: If E40-E43 are not all on, the phase clock is received from an external source through the J4 serial-

port connector, and the settings of E3 – E6 are not relevant.

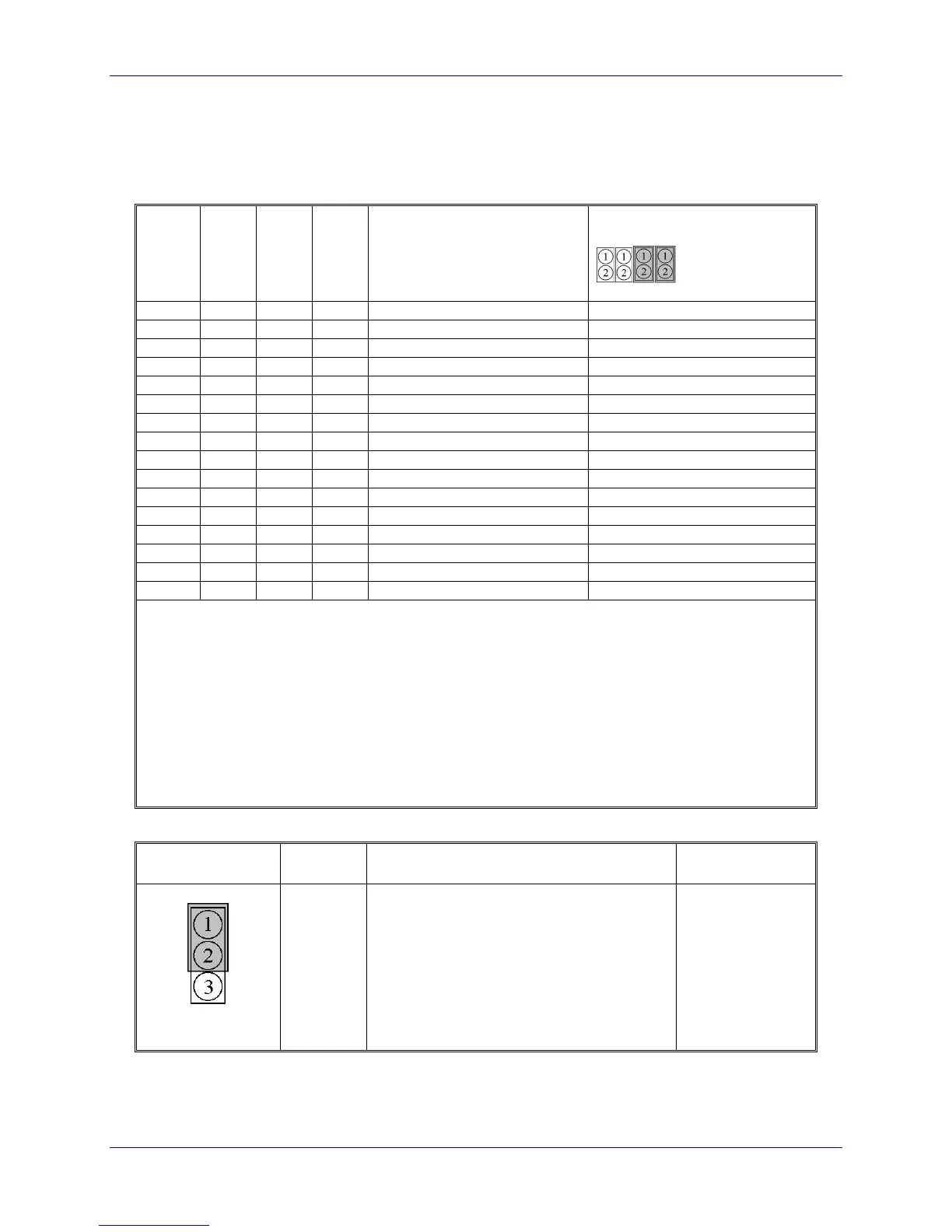

E7: Machine Input Source/Sink Control

E Point and

Physical Layout

Jump pin 1 to 2 to apply +5V to input

reference resistor sip pack; this will bias MI1

to MI8 inputs to +5V for OFF state; input

must then be grounded for on state.

Jump pin 2 to 3 to apply GND to input

reference resistor sip pack; this will bias MI1

to MI8 inputs to GND for OFF state; input

must then be pulled up for on state (+5V to

+24V).

Loading...

Loading...