Chapter 7 Motion Control ASDA-M

7-32 Revision December, 2014

table

P5-81.

Data Size of E-Cam

table

It is set by P5-82. 720 points is the maximum and 5 points is

the minimum.

Data Format of

E-Cam table

32-bit signed value.

Data Content of

E-Cam table

Save the position of slave axis (User unit, PUU)

Features of E-Cam

The operation of

E-Cam position

The master axis operates by incremental command input.

The slave axis issues position command incrementally.

The start and the end of E-Cam curve profile could not

always be the same. It depends on the value of E-Cam

table.

The command is interpolated by cubic curve. The torque on

each point will be smoothly connected because of quadratic

differential operation.

DO.CAM_AREA

(DO no.= 0x18)

Digital Output (DO): CAM_AREA. If this DO is ON, it means

the E-Cam axis is in the setting area.

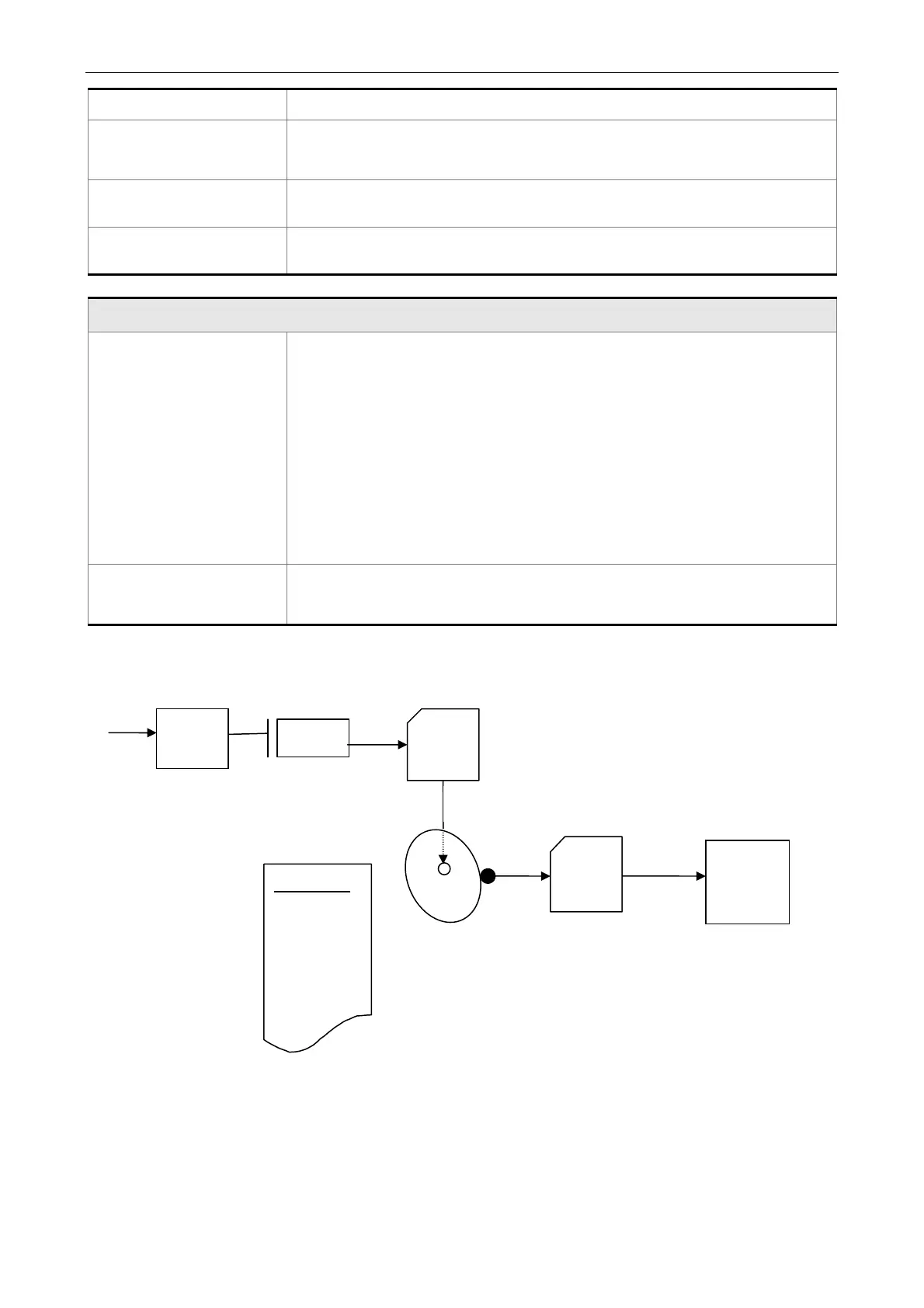

E-Cam provided by this servo drive and below is its functional diagram:

(pulse)

Pulse command

Slave axis

(PUU)

Slave axis

Clutch

Gear box

#2

P5-88.Y

setting

value

P5-88.ZU engaged

method

P5-87 lead pulse

P5-89 Engaged

distance

P5-84: Pulse number sent by master axis

P5-83: E-cam rotation cycle

P5-81: Table address

P5-82: Data amount N

P5-85: Entering point

P5-19: Table scale

Data array

…..

POS 0

POS 1

~

P1-44: gear ratio

(numerator)

P1-45: gear ratio

(denominator)

Master

axis

P5-88.X

setting

value

Position

controller

E-cam axis

Cam

Gear box

#1

Loading...

Loading...