Chapter 5 Methods of Anomaly Diagnosis | VFD-VJ

5-17

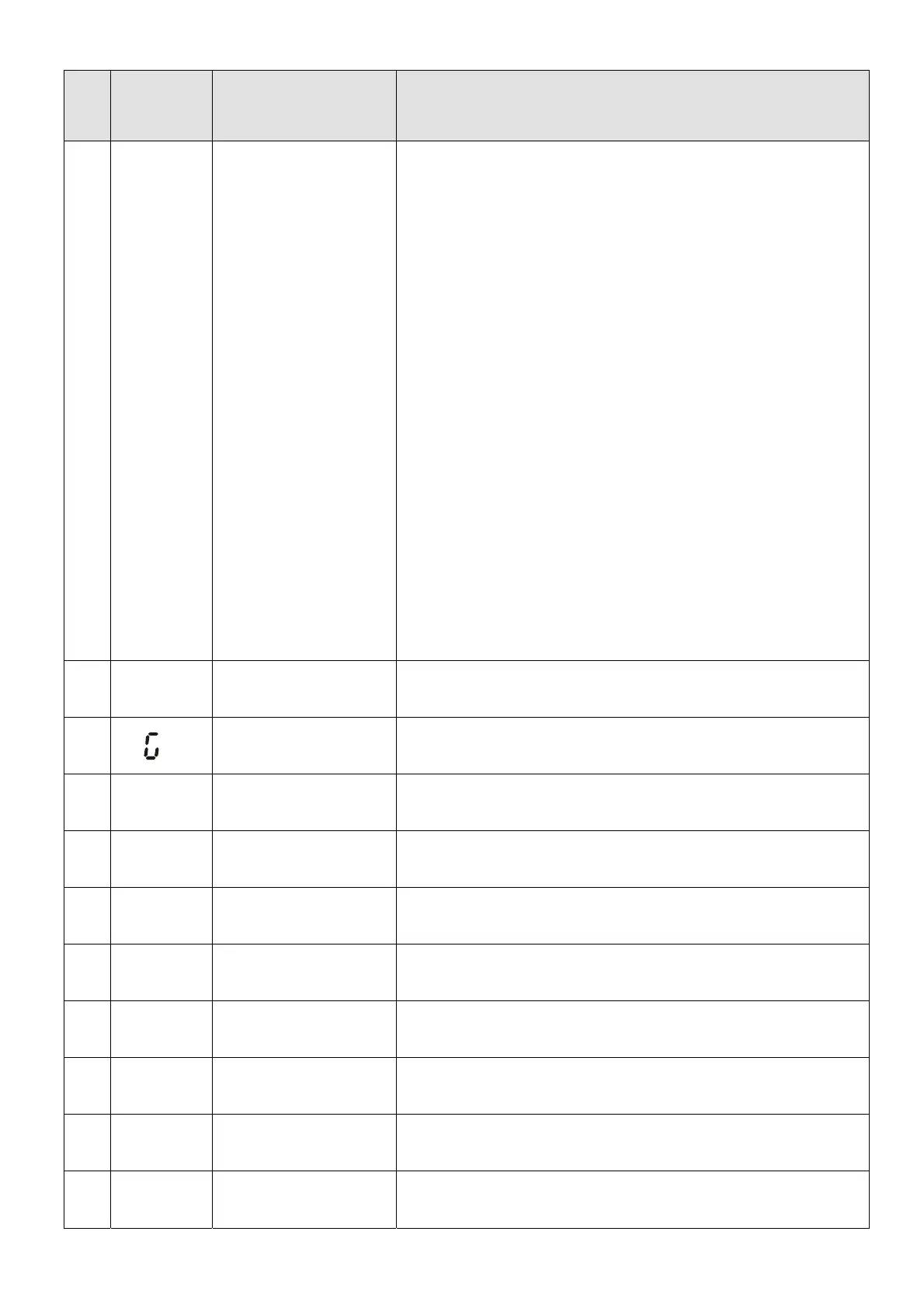

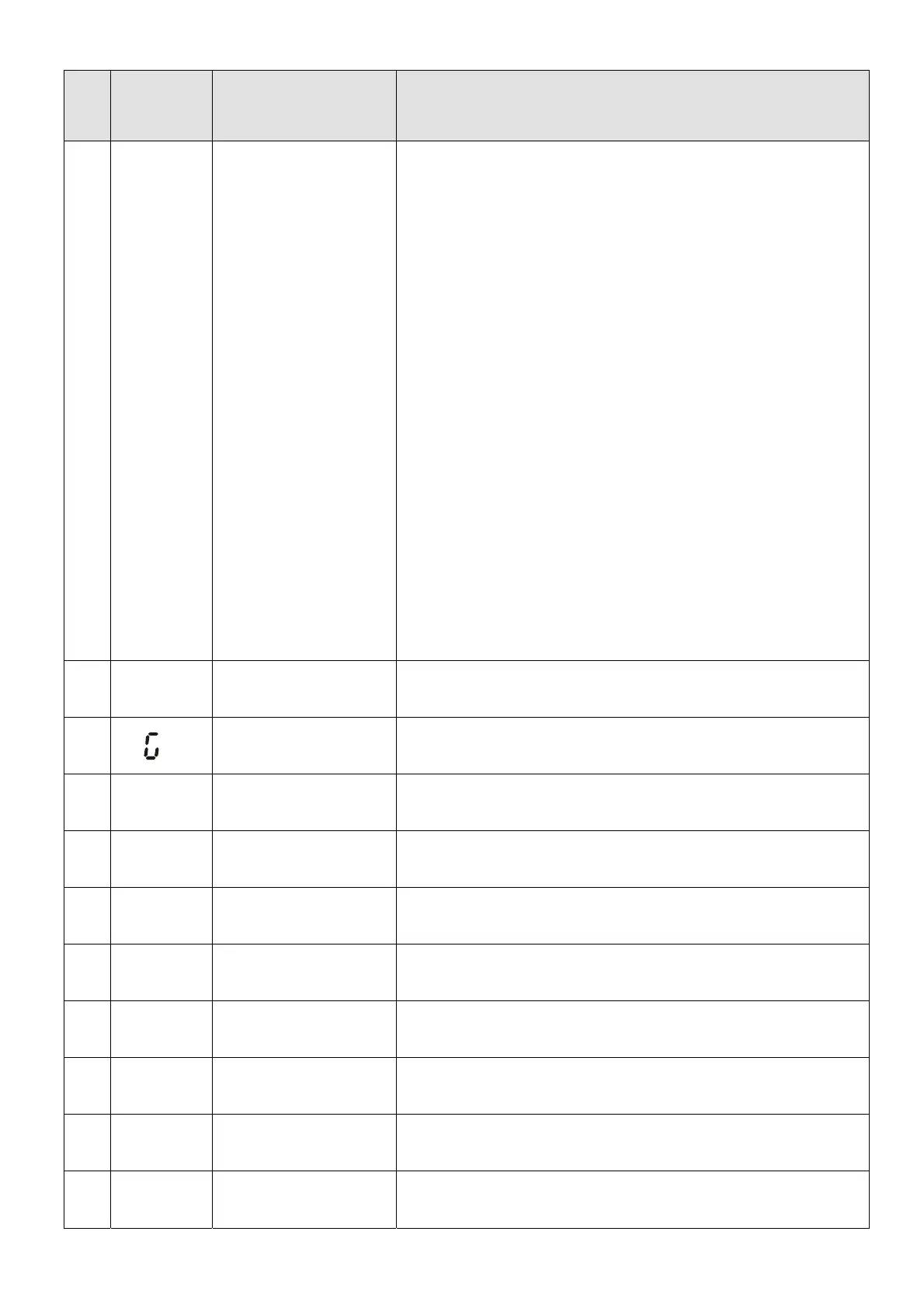

No.

Display

Fault codes defined

by Delta

(2021H High Byte)

Descriptions

A27

001BH

The function of this warning code is to prevent oil pump from

damaging while running without sucking in any hydraulic oil.

When the hybrid servo drive goes from STOP to RUN, it starts

to check if the pressure is over 0.5Bar within the time set at

Pr.00-60. During this checking period, the servo drive refuses

pressure command and flow command sent from keypad. The

keypad displays bp (building pressure).

If the pressure is still under 0.5bar after the checking period

set at Pr.00-60, there will be an oil shortage warning and the

hybrid servo drive will stop running. The keypad will display

noil (no oil).

If the pressure is over 0.5bar within the checking time set at

Pr00-60, the hybrid servo drive continues to run normally.

There won’t be a bp warning. (bP)

※ This function is effective when Pr.00-27 <minimum

pressure> is

set as higher than 0.3% and the time setting at Pr.00-60

is NOT 0.

A28

001CH Output Phase Loss (oPHL)

A36

0024H Software error 1 occurred on CANopen (CGdn)

A37

0025H Software error 2 occurred on CANopen (CHbn)

A38

0026H CANopen Synchronization off (CSyn)

A39

0027H CANopen bus off (CbFn)

A40

0028H CANopen index error (CIdn)

A41

0029H CANopen station address error (CAdn)

A42

002AH CANopen memory error (CFrn)

A43

002BH CANopen SDO transmission time-out (CSdn

A44

002CH CANopen SDO received register overflow (CSbn)

Loading...

Loading...