Chapter 4 Description of Parameters | VFD-VJ

4-27

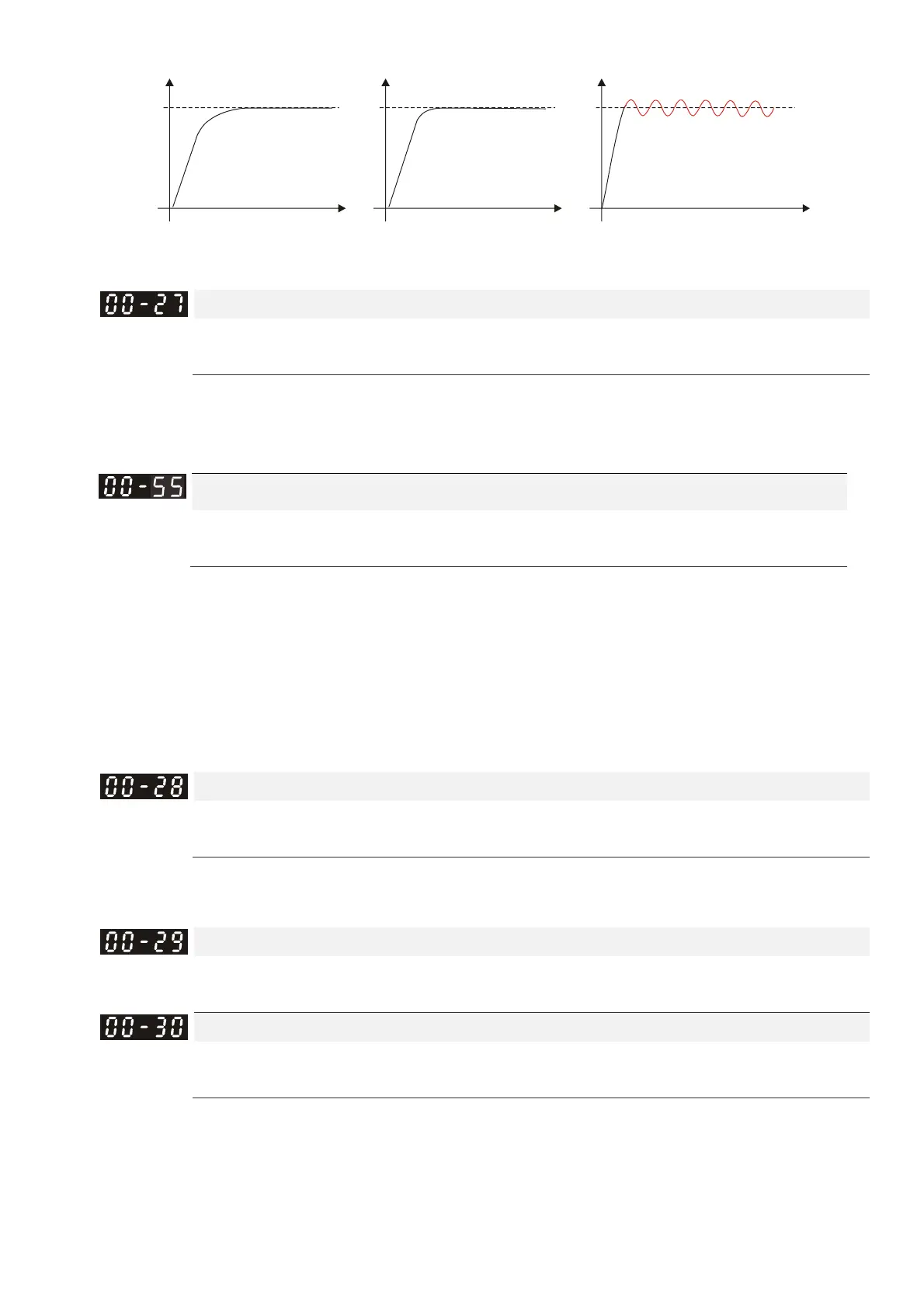

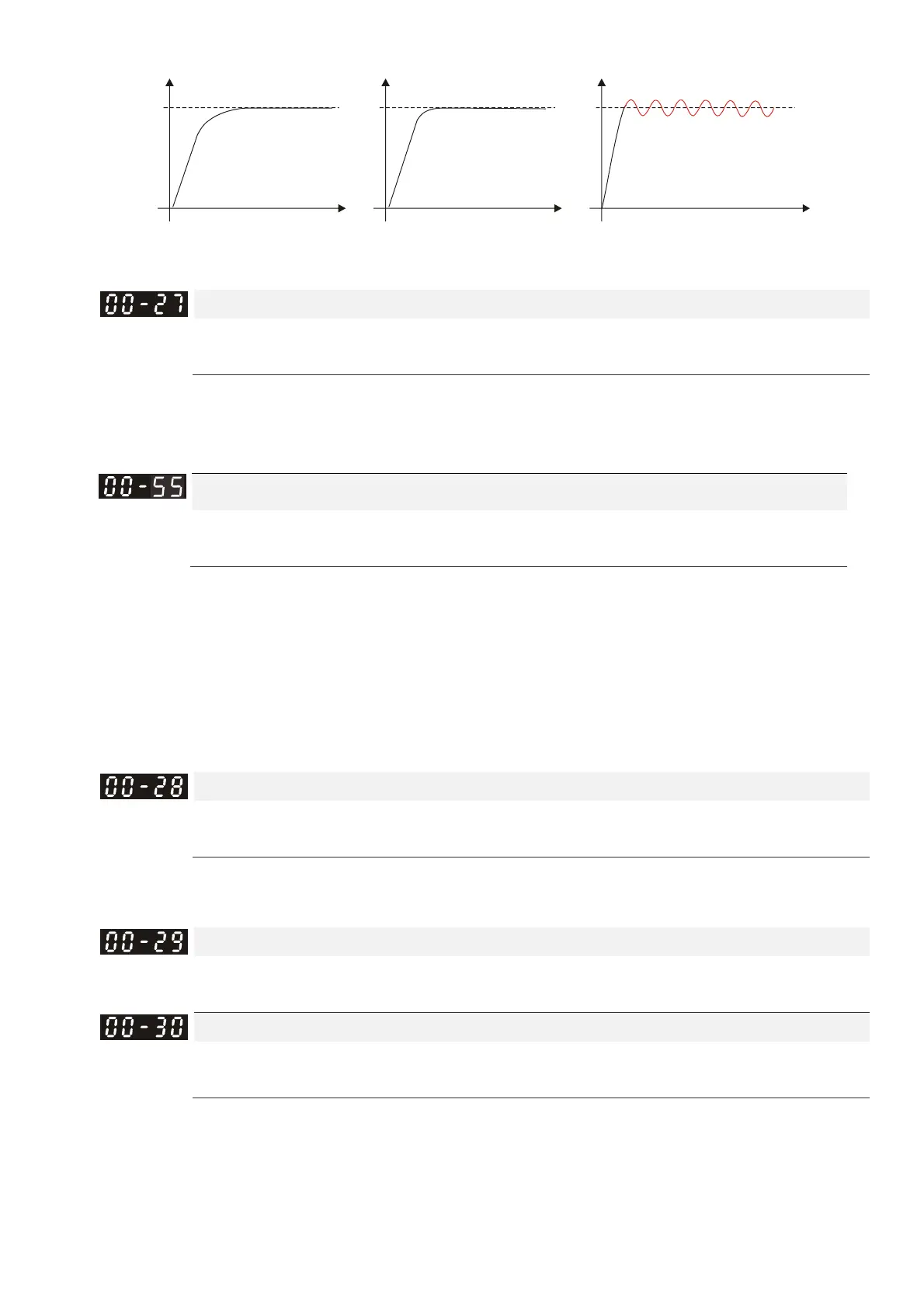

Appropriate Kd value

Kd value is too low

Kd value is too high

Minimum pressure

Control mode

VF FOCPG FOCPM

Factory setting: 0.1

Settings 0.0~100.0%

Set the minimum pressure value 100% corresponding to Pr.00-08

Maintain a minimum pressure to ensure that the oil pipe is in fully filled condition to avoid the activation delay

of the cylinder when a pressure/flow command is activated.

Minimum flow

Control mode

VF FOCPG FOCPM

Factory setting: 5.0

Settings

0.00 ~ 100.00%

The setting at Pr.00-08 is the setting of Pr.00-27 at 100%. The setting at Pr.01-02 is the setting of Pr.00-55

at 100%.

A minimum pressure must be maintain to ensure the oil circuit is full at all to time. This will prevent delay of

oil tank activation when receiving a pressure/ flo

w rate command.

When the pressure command is 0, keep the minimum pressure (Setting value of Pr.00-27).

When the pressure command is below the minimum pressure but over 0.7bar, the hybrid servo drive follows

the pressure command to do control. For example, when the pressure command is 1 bar, the hybrid servo

drive follows this command to keep the pressure at 1 bar.

When the pressure command is lower than 0.7bar, the hybrid servo drive keeps the minimum pressure.

Depressurization speed

Control mode

VF FOCPG FOCPM

Factory setting: 25

Settings 0~100%

Set the highest rotation speed at depressurization. The 100% value is mapped to Pr.01-02 (the maximum

rotation speed of the motor)

Ramp up rate of pressure command

Control mode

VF FOCPG FOCPM

Factory setting: 0

Settings 0~1000ms

Ramp down rate of pressure command

Control mode

VF FOCPG FOCPM

Factory setting: 100

Settings 0~1000ms

Ramp the pressure value for the pressure command to reduce the vibration of the machine.

Set the time required for ramping the pressure from 0 ~the maximum pressure (Pr.00-08).

Loading...

Loading...