8.5.8 Brake

8.5.8.1 Brake assignment

SWL Chain hoist Reeving Motor size Brake Max. brake displacement

[kg]

DC-Com [mm]

80 - 125 1

1/1

ZNK 71 B 8/2

BK03

0,6

160 - 250

2

315 - 500 5 ZNK 80 A 8/2

630 - 1000

10

ZNK 100 A 8/2

BK07

1250 - 2000 2/1 ZNK 100 B 8/2

Tab. 65

8.5.8.2 Check brake wear

Since 04/2009, depending on the size, the brakes have gradually been equipped with plugs in the brake housing,

so that the brake does not have to be dismantled for checking brake wear. Brake wear is checked via the air gap.

● When the max. brake displacement is reached (see ⇒ Tab. 65, Page 94), the brake must be immediately replaced.

● For brake displacements up to 0,5 mm, the brake can still be used until the next maintenance is due.

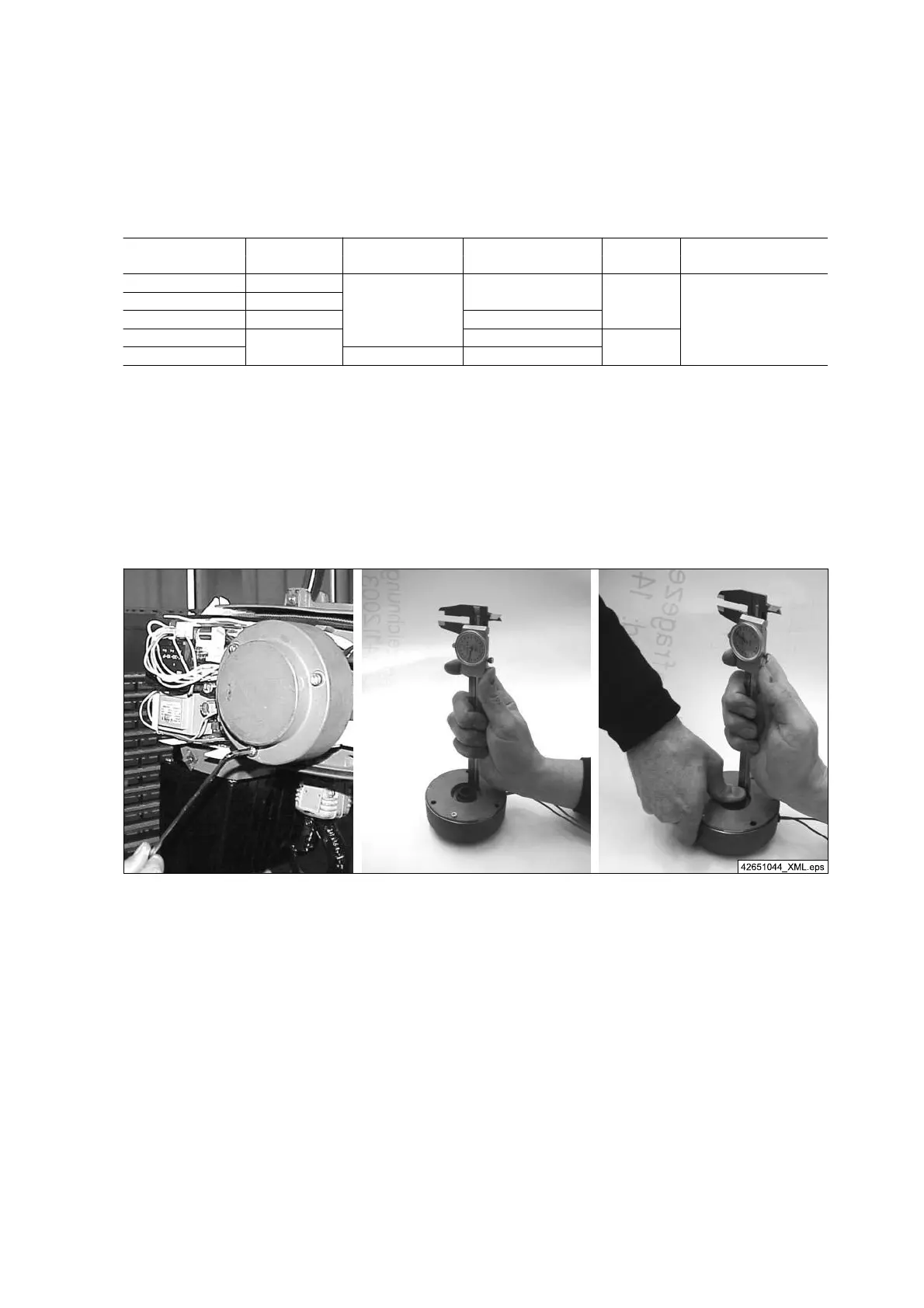

Until year of manufacture 03/2009

Fig. 64

Disconnect chain hoist from power supply (mains connection switch) and secure against restarting.

● Open the electrical equipment cover.

● Disconnect brake connector.

● Dismantle brake.

Measure brake wear with calliper gauge as follows:

● Measure the distance from brake rear side to brake disk with depth gauge or calliper gauge when the brake is

not actuated.

● Measure the distance from brake rear side to brake disk with depth gauge or calliper gauge when the brake is

actuated, to do this, press the brake disk against the springs until it stops;

● Use both measured values to calculate the difference; this difference is the brake displacement.

94

21480244/181209

Loading...

Loading...