3

1

2

4

5

6

7

5

b1

b2

6

7

4

9

1

8

b1

2

42583844.eps

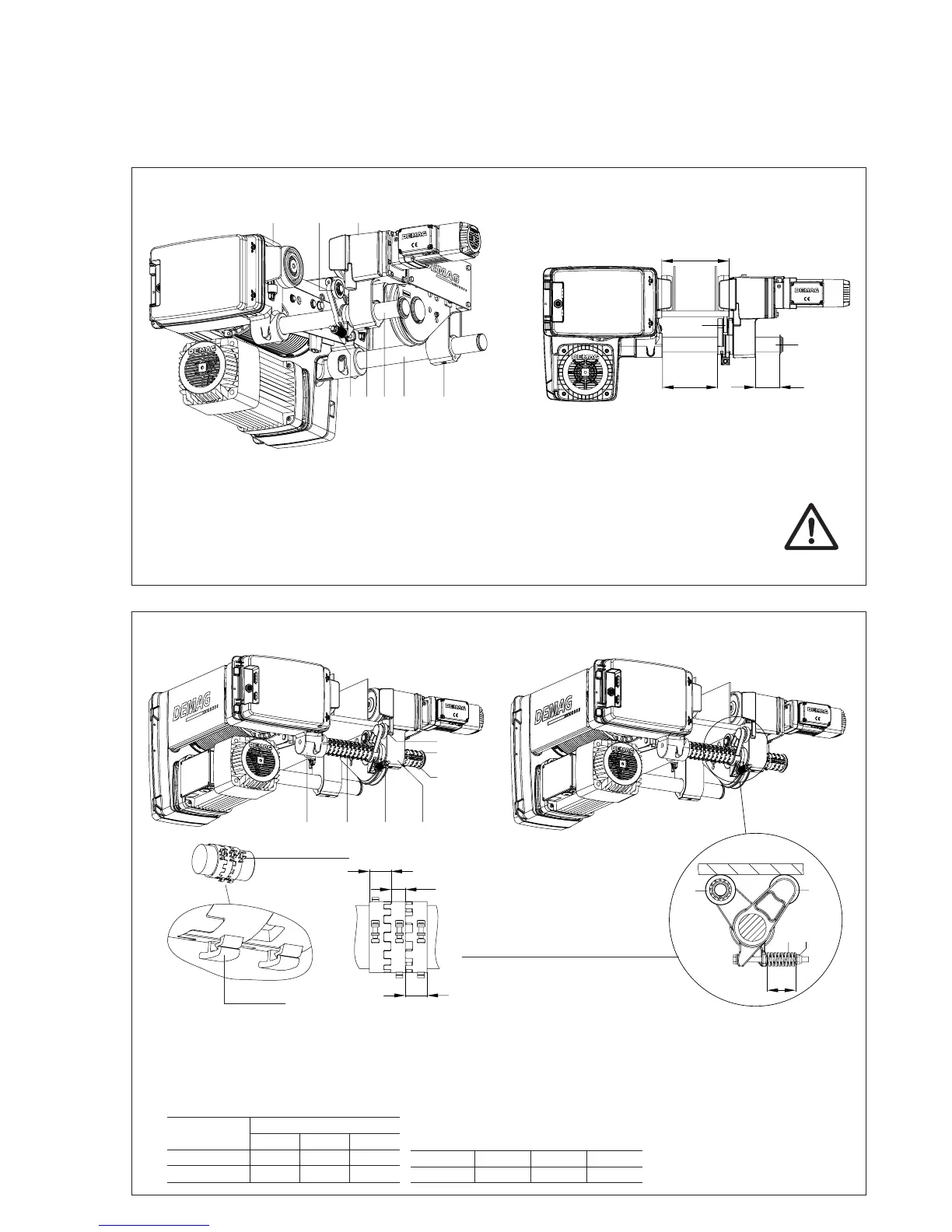

Place the travel rollers of wheel legs (4) – drum side – onto the girder flange and slide wheel legs (1) on the opposite

side – travel motor side – towards the girder.

Reference dimension between both opposite guide rollers is flange width b +1 mm.

After adjusting the travel unit, press supporting roller (6) against the bottom flange of the girder by means of tensioning

screw (7). Tension supporting roller (6) until the travel wheel is in contact with the girder flange.

Assembly of the travel unit on the track girder

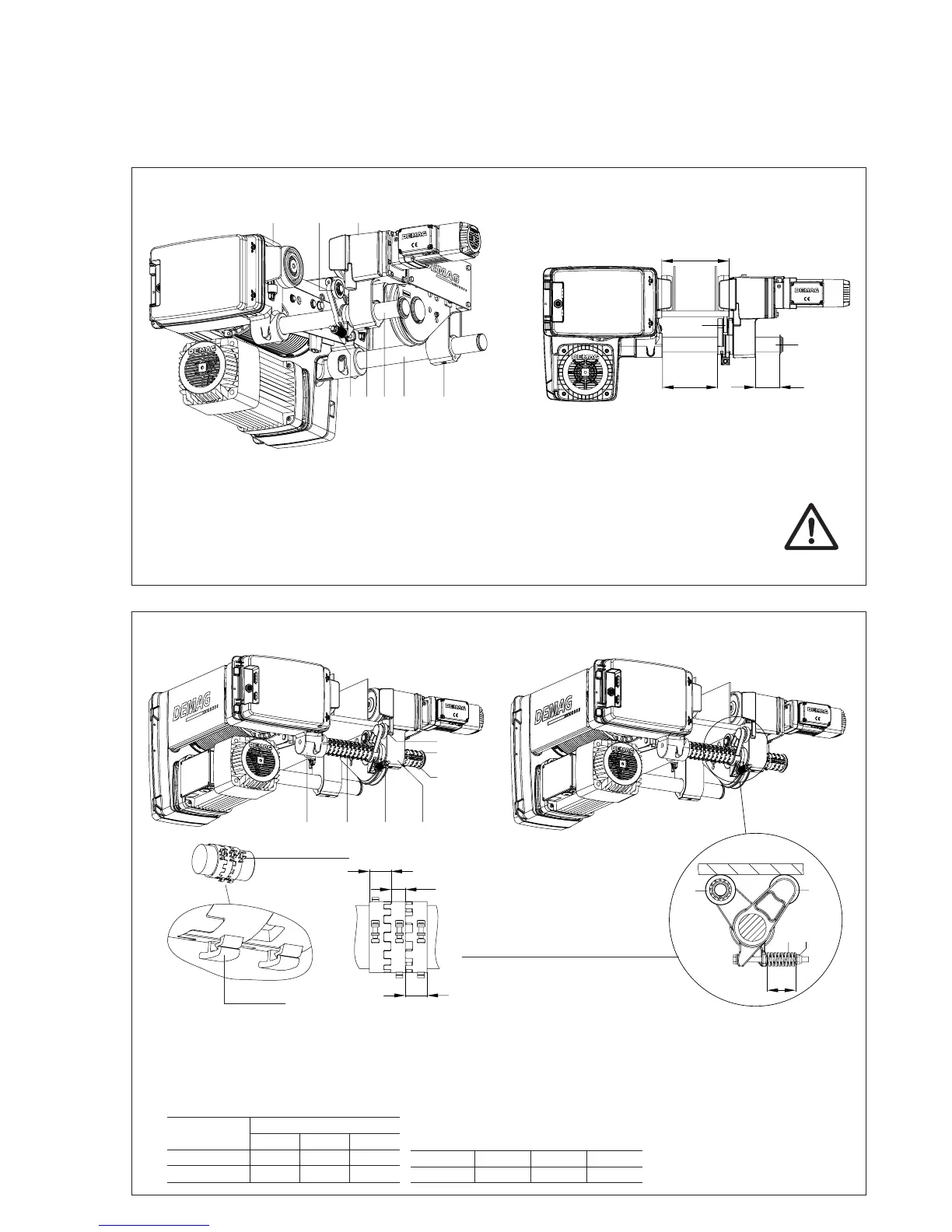

Assembly of the spacer sleeves

(only on the crossbar side with supporting roller)

1. Measure distance x1 between wheel legs (4) and supporting roller (6).

2. Measure distance x2 between wheel legs (1) and retaining ring with washer (8).

3. This is done to determine the number of spacer sleeves (9).

Spacer sleeve (9) is now opened and fitted on connecting rods (2).

Spacer sleeve dimensions (9)

egnaR

mmnihtdiW

1b2b2b+1b

5RD/3RD9,222,511,83

01RD3,228,411,73

Determine dimension L of pre-tensioned pressure spring (10).

To obtain the pressure force of supporting rollers (6), shorten

length L of pressure spring (10) by “dimension x”.

egnaR3RD5RD01RD

]mm[x-.miD2,6-2,5-5,7-

42583744.eps

Final adjustment of the supporting rollers

L

6

6

7

10

Fit the clamps for fastening

the cable in one row.

Locking hook

Pre-tensioning of pressure spring (10)

After having adjusted the travel unit, press support-

ing roller (6) against the bottom flange of the girder

by means of tensioning screw (7). Tension support-

ing roller (6) until the travel wheel is in contact with

the girder flange.

42584044.eps

42583944.eps

Fix side cheek (1) on connecting rod (2+3)

with threaded pins (5).

DR 3 range = 150 Nm

DR 5/10 range = 200 Nm

Minimum flange thickness

DR 3 min. 10 mm

DR 5 min. 12 mm

DR 10 min. 15 mm

Loading...

Loading...