7.1 11 95-8242

DETECTOR POSITIONING AND DENSITY

The detector has a nominal 90° cone of vision. What this

means in practical terms can be understood by reference

to a typical installation. Consider an application such as

a loading rack with a ceiling height of 25 feet (7.5 meters),

and assume it is desired to have complete detector

coverage at floor level. If a detector is mounted 2 feet

(0.6 meter) from the ceiling and pointed straight down, the

distance from the detector to the designated level would

be 23 feet (7 meters). Because of its 90° cone of vision,

the detector would cover a circular area with a diameter

of 46 feet (14 meters) at the designated level. A simple

layout of the area to be covered will easily reveal the

number of detectors required to completely supervise the

designated area. In general, detectors should be placed

as close as practical to the probable hazard.

NOTE

Do not mount UV detectors close to the ceiling in

enclosed areas if dense smoke can be expected

to accumulate at the onset of a re. Mounting the

detector on side walls a few feet (or about 1 meter)

down from the ceiling will normally allow time for

the detectors to respond before they are affected

by smoke rising to the ceiling. It is also advisable

to shorten any time delay settings for applications

where smoke may accumulate during a re. If

dense smoke can be expected to accumulate prior

to the presence of ame (as in an electrical re), do

not use UV detectors alone.

MOUNTING THE DETECTOR

The following procedure should be used for mounting

and wiring the detectors.

1. Detectors should be located for the best unobstructed

view of the area to be protected. Detectors must

be accessible for cleaning the viewing window and

reflector rings. Care must be taken so that dirt or other

foreign material will not accumulate and obscure the

detector viewing window. For outdoor applications,

the detectors should be pointed downward to prevent

the cone of vision from scanning the horizon, since the

detectors can be affected by long duration lightning

flashes or distant arc welding. When practical,

mount the detectors so that the UV test lamp is on

top, since dirt accumulation between the window and

the reflector ring can interfere with the Automatic o

i

function.SeeFigure4formountingdimensions.

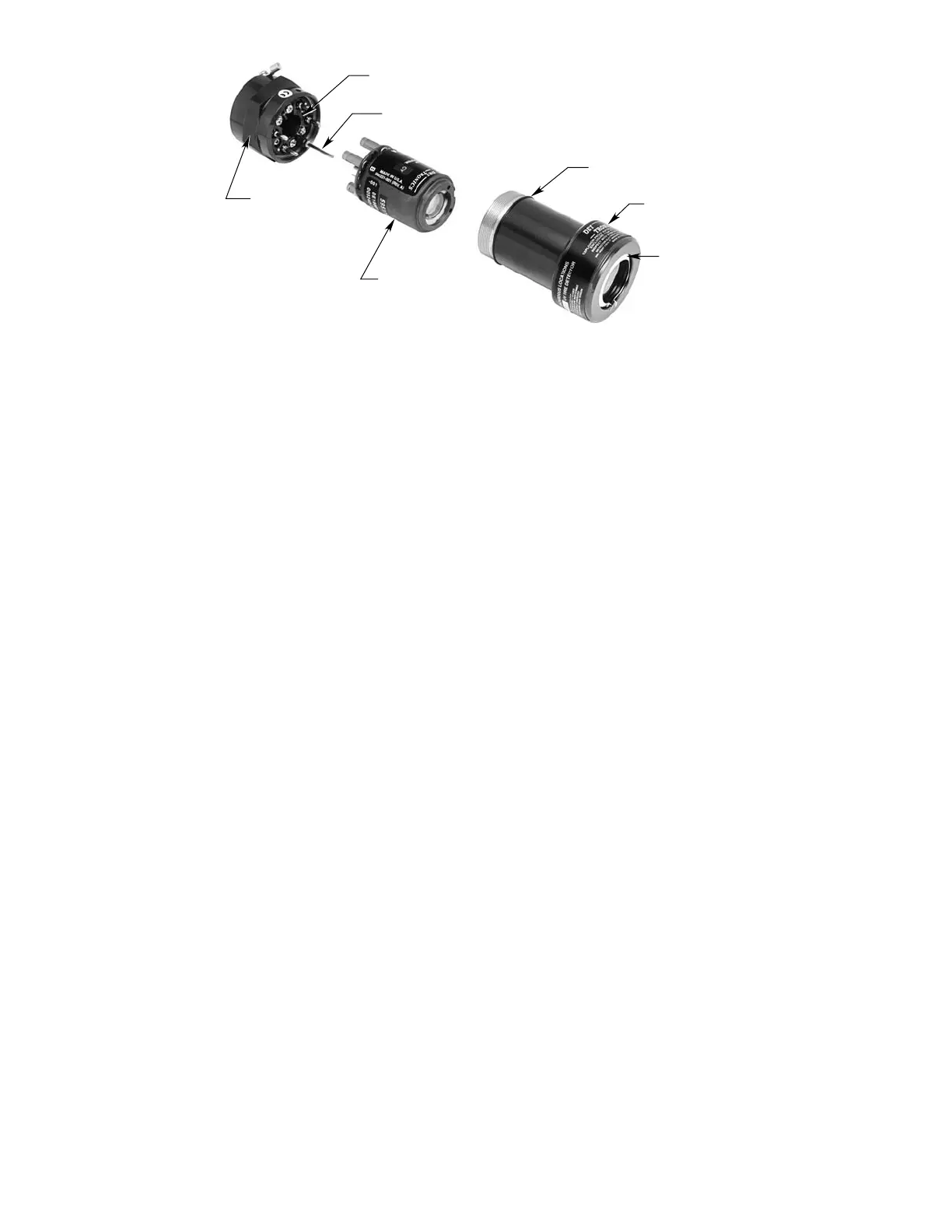

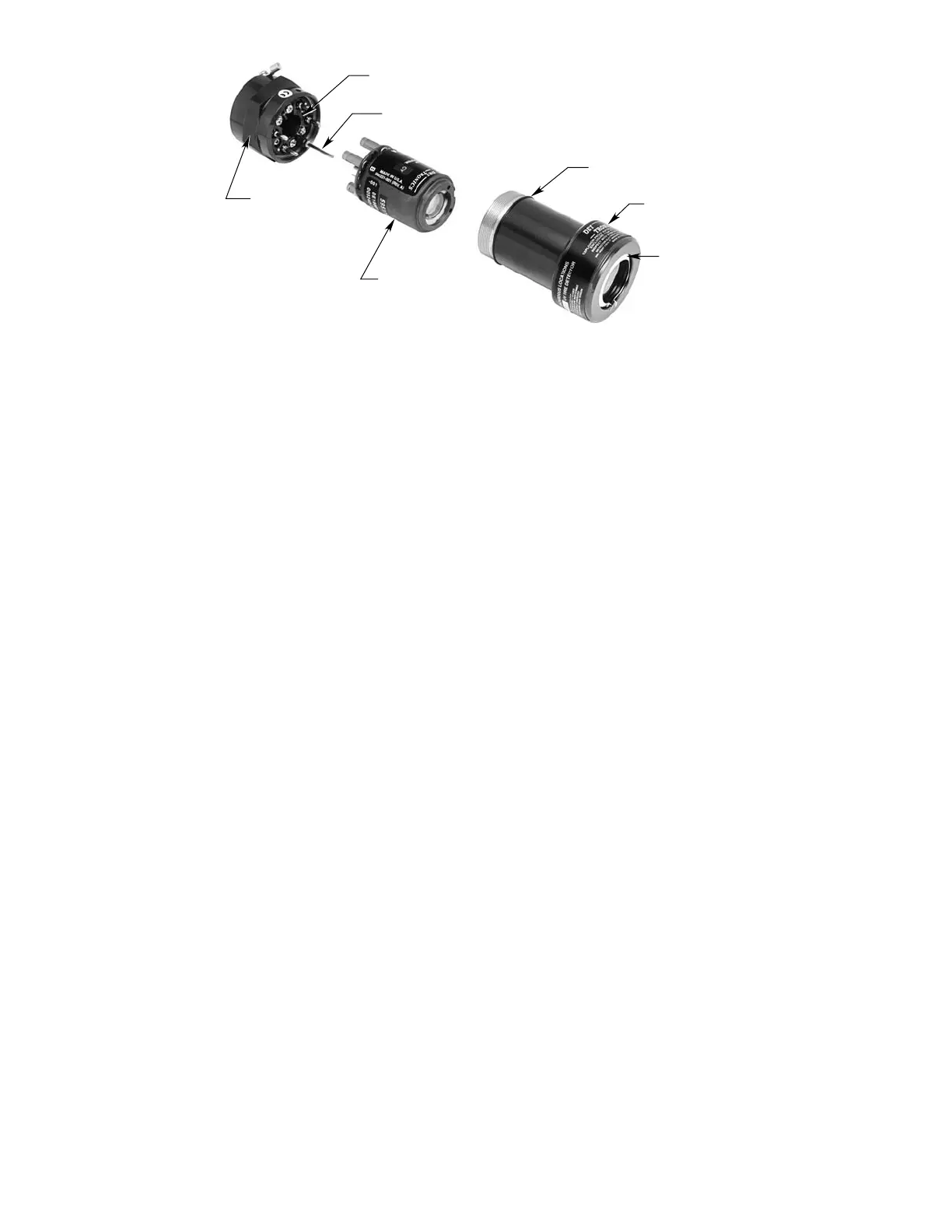

2. Disassemble the detector enclosure by turning the

housing cover counterclockwise. If the detector is

equipped with a cover locking device, loosen the

clamp and disengage the “catch” from the terminal

cap. See Figure 9 for an illustration of the detector

assemblyandFigure10fortheoptionalcoverlocking

assembly.

NOTE

Power must not be applied to the system while

opening the detector housings, or while plugging in

or removing the sensor tube modules.

3. Install the A-, B-, C-, and D-leads to the connections

ontheterminalblock.SeeFigure11.Donotground

the shield to the detector housing.

TERMINAL BLOCK

INDEX PIN

O-RING

WINDOW AND HOUSING

Oi REFLECTIVE RING

UV SENSOR MODULE

TERMINAL CAP

A2078

Figure 9—C7050 Detector

Loading...

Loading...