95-8768142.1

NOTE

It is highly recommended that a complete

spare be kept on hand for eld replacement

to ensure continuous protection.

MAINTENANCE

IMPORTANT

Periodic flamepath inspections are not

recommended, since the product is not

intended to be serviced and provides

proper ingress protection to eliminate

potential deterioration of the amepaths.

WARNING

To avoid a potential electrostatic discharge

(ESD), the painted surface of the detector

should only be cleaned with a damp cloth.

WARNING

The sensor module (“front” half of the

detector) contains no user serviceable

components and should never be tampered

with.

NOTE

Refer to the X3302 Safety manual, number

95-8720, for specific requirements and

recommendations applicable to the proper

installation, operation, and maintenance of

all SIL-Certied X3302 Flame Detectors.

To maintain maximum sensitivity and false

alarm resistance, the viewing windows of the

X3302 must be kept relatively clean. Refer to the

following procedure for cleaning instructions.

CLEANING PROCEDURE

CAUTION

Disable any extinguishing equipment that is

connected to the unit to prevent unwanted

actuation.

To clean the windows and

o

i

reflector plate, use

the window cleaner (p/n 001680-001) and a soft

cloth, cotton swab, or tissue and refer to the

following procedure.

1. Disable any extinguishing equipment that

is connected to the unit.

2. Since the X3302 is less affected by

contamination than other detectors, removal

of the

o

i

reflector plate is needed only under

extreme conditions. In addition, it is not

necessary to achieve perfect cleanliness,

because IR is not significantly absorbed

by slight films of oil and/or salt. If a fault

condition is still indicated after cleaning,

remove and clean the

o

i

reflector plate

using the

o

i

Reflector Plate Removal and

Replacement procedure.

3. Clean all three viewing windows and

reflector surfaces thoroughly. Use a

cotton swab and the Det-Tronics window

cleaning solution. Use Isopropyl alcohol for

contaminations that the Det-Tronics window

cleaning solution can not remove.

IMPORTANT

When used in extreme environments, the

reective surface of the detector

o

i

reector

plate may eventually deteriorate, resulting

in reoccurring

o

i

faults and the need for

o

i

reector plate replacement.

o

i

REFELCTOR PLATE REMOVAL AND

REPLACEMENT

1. Disable any extinguishing equipment that

is connected to the unit.

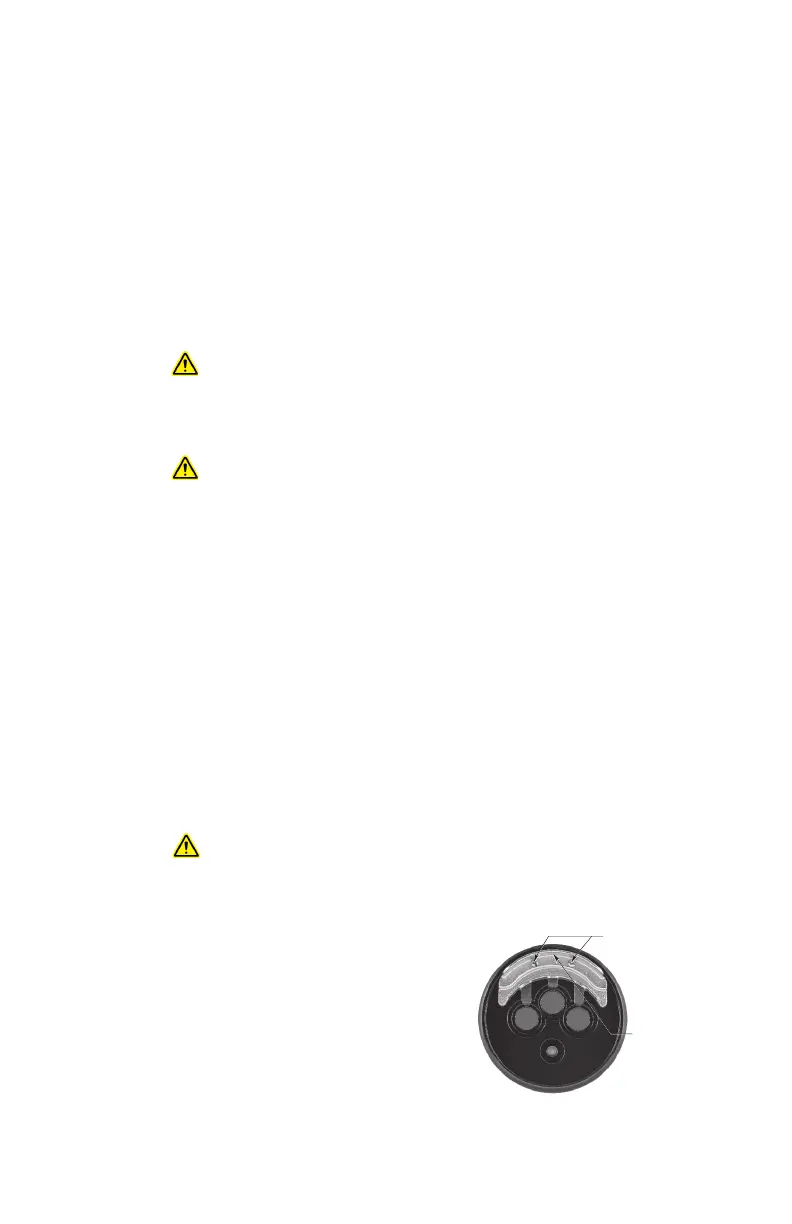

2. Loosen the two captive screws, then grasp

the o

i

reflector plate by the visor and remove

it from the detector. See Figure 19.

3. Install the new (or cleaned) o

i

reflector plate.

NOTE

When installing the stainless steel

o

i

reflector plate, ensure that the gasket is

present and correctly seated to prevent

moisture or contaminants from penetrating

behind the

o

i

reector plate. To ensure even

seating, tighten both screws equally.

LOOSEN TWO CAPTIVE SCREWS

GRASP VISOR AND

REMOVE o

i

REFLECTOR PLATE

B2106

Figure 19

—

o

i

Reector Plate Removal

Loading...

Loading...