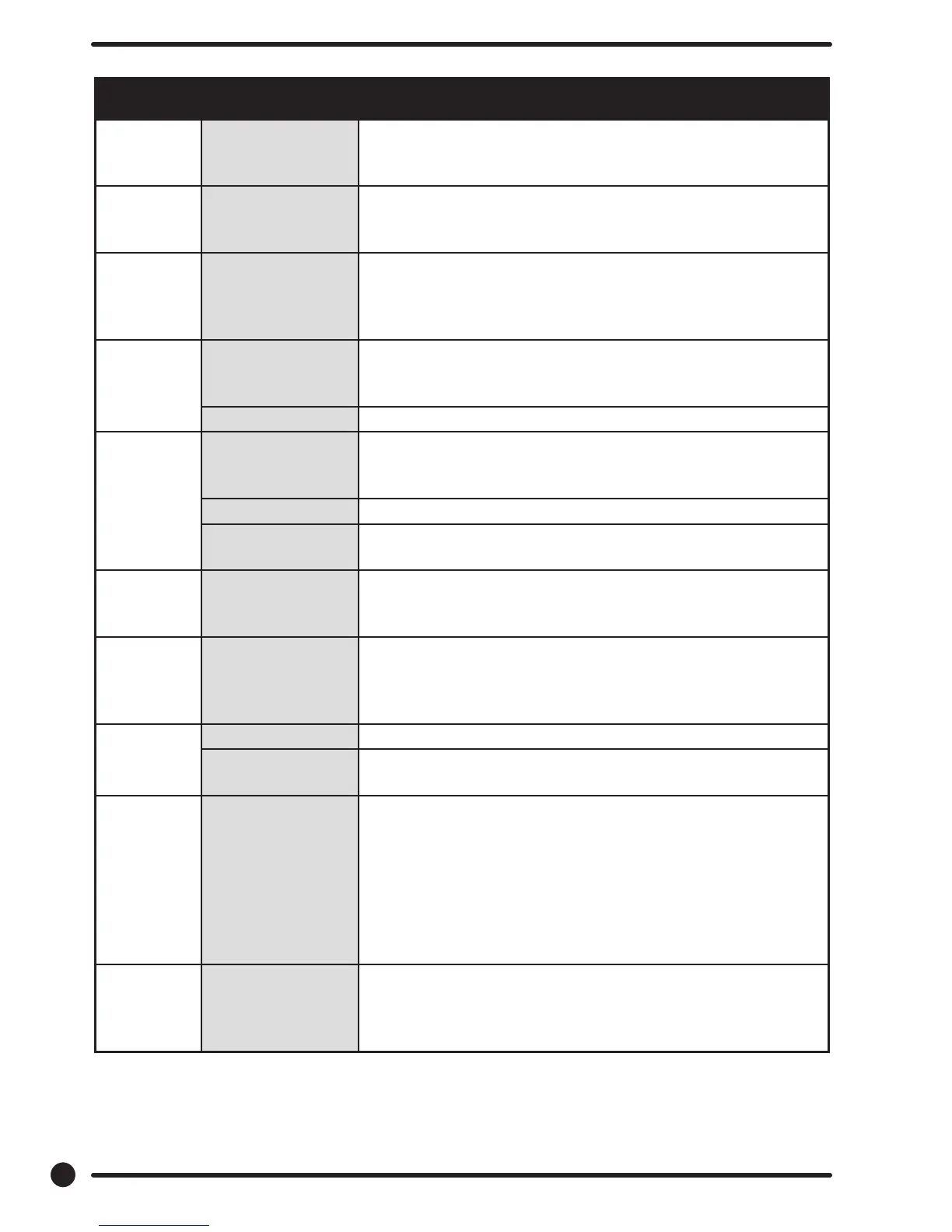

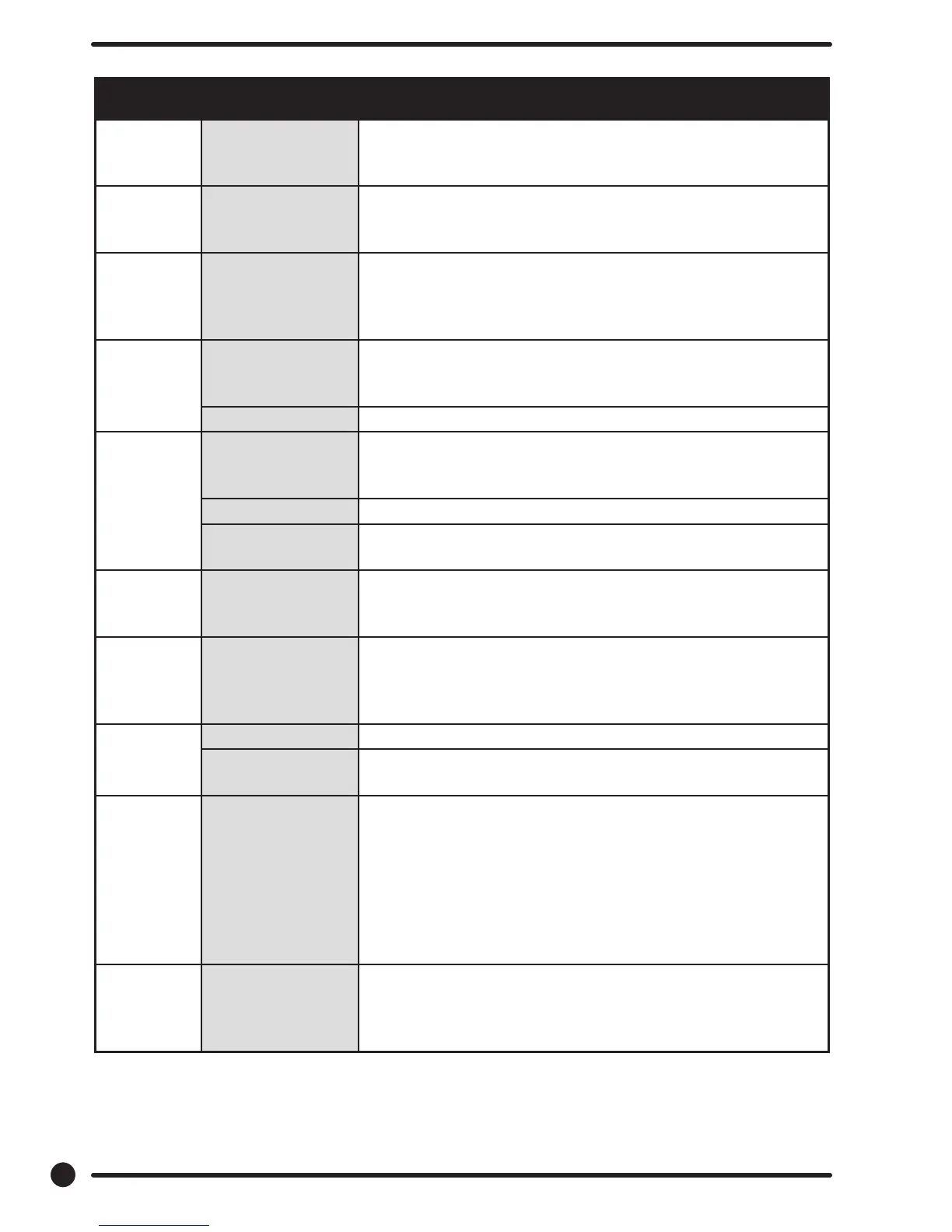

Symptom Probable Cause Suggested Remedy

Water level

too high

Pressure Switch Check for blockage in pressure switch hose. Check for

pressure switch opening circuit across terminals . Replace

switch if contacts do not open.

Water

drains

slowly

Drain System Check hoses and drain valve for blockage. Clean of inad-

equate size. if necessary. Check building drains for blockage

Machine

does not

turn

VFD Check VFD by removing top panel and record power or fault

lights are iluminated. If the fault light is on, turn power o

to machine at breaker for 2 minutes and turn poiwer back

on to reset. If still no display replace VFD

Machine

tumbles in

one direc-

tion

VFD Remove Top cover record if power light of fault lights are

displayed, wee front control for related codes. See fault code

section for more info.

VFD Inspect yellow enable wires from main relay PCB and at VFD

Excessive

vibration

Mounting System Check these areas: • Strength of mounting structure, con-

crete or base. • Mounting bolts may be loose and need

tightening.

Drive Belt Worn drive belt can cause vibration and noise.

Loading Note: Small loads contribute to out of balance loading and

increase vibration.

Machine

does not

spin

Pressure Switch Check pressure switch for continuity across terminals #21 &

#22 indicating pressure switch has reset to the empty posi-

tion. If no continuity, change pressure switch.

Machine

starts and

does not

operate

VFD Check yellow enable wires from relay PCB P13 & motor

P14to VFD advances through cycle are connected. Check

fault code on VFD before removing power from the drive.

Check orange P-15 wire for signal from door switches.

Machine

does not

stop

Main PCB Main PCB controls time cycle at end of cycle

Braking Resistors Check braking resistors for continuity. Verify ohms resis-

tance by Molex.

Water leak-

age around

loading door

Door Adjustment Door may need adjustment due to abuse or wear. Check

tightness around perimeter using a dollar bill. Adjust left

to right tightness by shims at door lock or hinge side. It is

important to center gasket to tub opening before tighten-

ing door to hinge bolts. Chalk may be used on tub front

to show point of contact with tub. If gasket is deformed,

worn, or damaged, replace. Refer to parts section for door

gasket expander kit.

Machine

Starts goes

Directly to

end of cycle

E-Stop buttor or

switch

If machine says PUSH then goes directly to “0” or “00” may

be bad stop Button or switch. Replace switch assembly.

Common Troubleshooting Solutions

56

Part # 8533-081-001 1/18

Loading...

Loading...