www.dimplex.de 452172.66.10-EN · FD 0311 EN-21

LIA 0608BWCF M - LIA 1316BWCF M English

Connecting electronically regulated circulating

pumps

Electronically regulated circulating pumps may have high start-

ing currents, which may reduce the service life of the heat

pump manager. If the starting current value is high, or is un-

known, install a coupling relay. The coupling relay must be sup-

plied by the customer. This is not necessary if the maximum

permissible operating current of the heat pump manager (see

specifications in the electrical documentation) is not exceeded

by the electronically regulated circulating pump or a relevant

approval has been issued by the pump manufacturer.

The high-efficiency pumps (UPH) are supplied with the

relevant coupling relay for connecting and operating the

electronically regulated circulating pump.

!

It is not permitted to connect more than one electronically

regulated circulating pump via a single relay output.

7.2.3 Frost protection

Regardless of the settings for the heat circulating pumps, they

always run in heating, defrost and frost protection mode. In sys-

tems with multiple heating circuits, the 2nd and 3rd heat circu-

lating pump has the same function.

!

To ensure that the frost protection function on the heat pump

works properly, the heat pump manager must remain

connected to the power supply and flow must be maintained

through the heat pump at all times.

!

The primary pump (M11 – responsible for the heat source flow

rate) and the secondary pump (M16 – responsible for the

warm/cold water flow rate) must always be clamped to the

heat pump manager in all cases. This is the only way to ensure

the pump flows and returns necessary for operation and to

ensure that the necessary safety measures are in place.

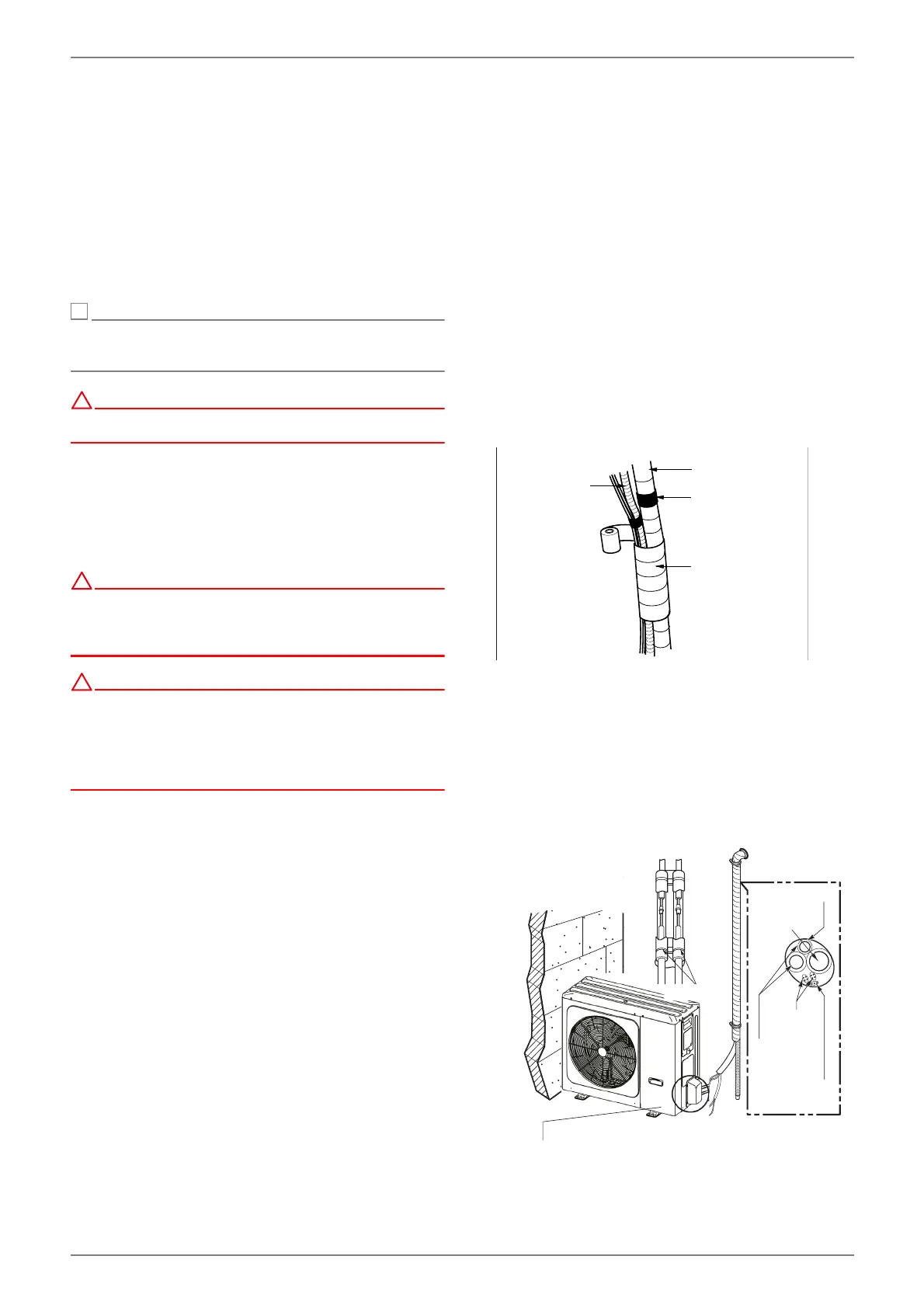

7.3 Final work

Once the pipes and electric cables have been connected, the

pipes must be bent and a leak test must be carried out. The leak

test must be carried out with particular care, as a refrigerant

leak results in a direct reduction in output.

Leaks are also difficult to identify once the installation is com-

plete.

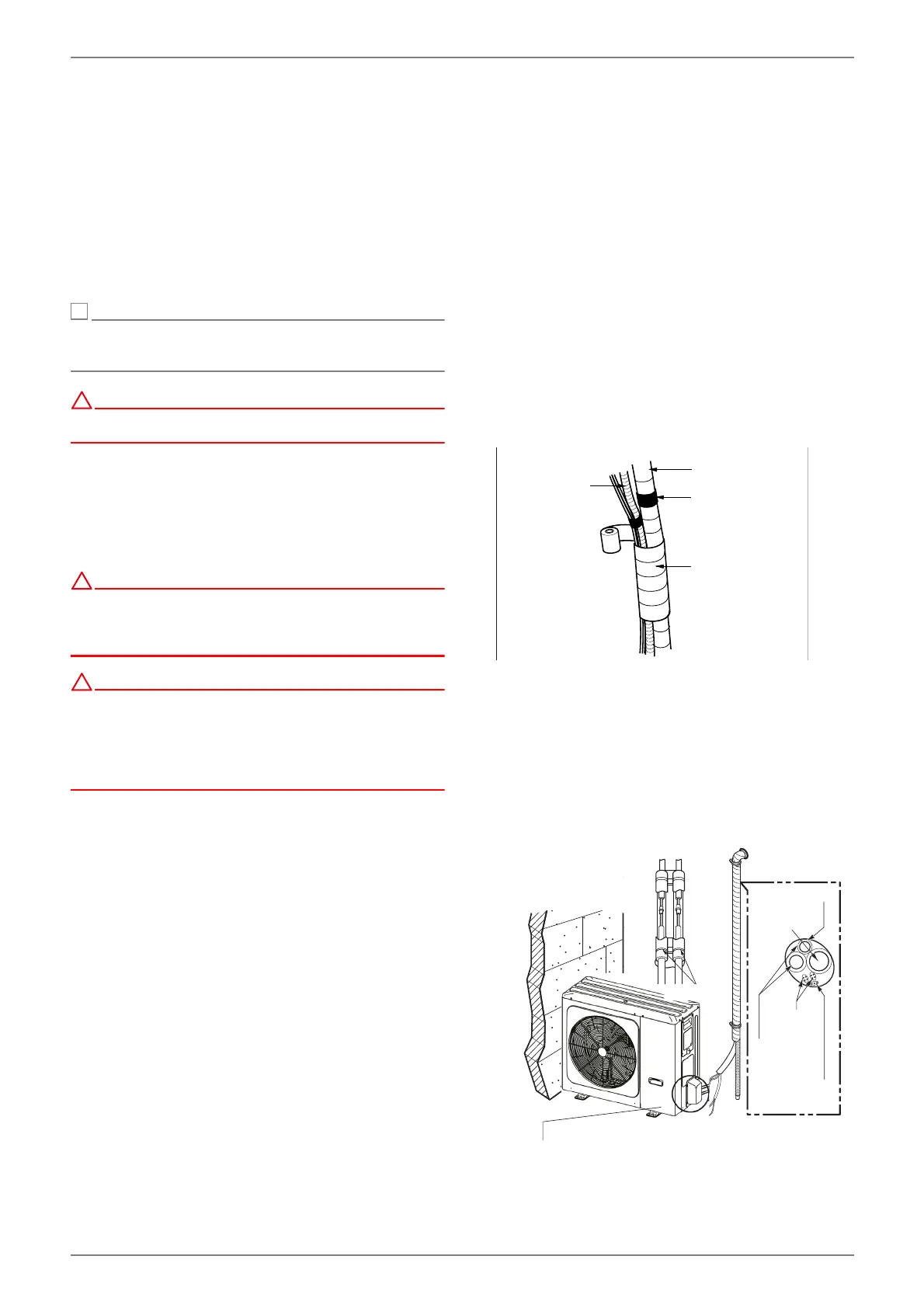

7.3.1 Pipe bends

Bend the pipes by covering the connection cable and refriger-

ant pipe (between the indoor and outdoor unit) with insulation

and fix the insulation in place with two adhesive tapes.

1) Fix the refrigerant pipe, mains cable and connection cable

with adhesive tape from bottom to top. Fix the bound pipe-

work along the wall.

2) Form a siphon to prevent water from entering the chamber

and electrical components.

3) Fix the pipework to the wall using clamps or similar.

Wrap the pipework in adhesive tape

1) Fix the pipes, mains cable and connection cable with adhe-

sive tape from bottom to top. If they are fixed from top to

bottom, rain could enter into the pipes or cables.

2) Fix the bound pipework along the external wall with clamps

or similar.

3) A siphon prevents water from entering the electrics.

'UDLQKRVH

QRWXVHG

Adhesive tape

(narrow)

Pipe

Wrapped in

adhesive tape

(wide)

A siphon prevents water from entering the electrics

Adhesive tape

Drain hose

(not used)

Refrigerant pipes

Connection cable

Mains cable

Seal a small

opening around

the pipings with

gum type sealer.

Seal small gaps

around the pipe,

e.g. with silicon.

KlebebandAdhesive tape

Loading...

Loading...