A-4

Check the Hydraulic Oil Level

Maintaining the hydraulic oil at the proper level

is essential to machine operation. Improper

hydraulic oil levels can damage hydraulic

components. Daily checks allow the inspector

to identify changes in oil level that might

indicate the presence of hydraulic system

problems.

Perform this procedure with

the platform in the stowed position and the

motor off.

1 Remove the hydraulic oil dipstick (fill cap),

wipe it clean and reinstall it.

2 Take the hydraulic oil dipstick out again,

and check the oil level.

3 If the hydraulic oil level is too low and add

new hydraulic oil to the prescribed level.

Original Hydraulic oil

specifications:L-HV46

Customers shall choose the appropriate

hydraulic oil according to the ambient

temperature used.

Example: L-HV32 or L-HV68

A-5

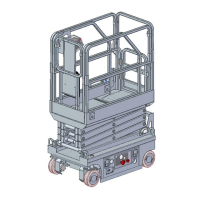

Perform Function Tests

Completing the function tests is essential to

safe machine operation. Function tests are

designed to discover any malfunctions before

the machine is put into service. A

malfunctioning machine must never be used. If

malfunctions are discovered, the machine

must be tagged and removed from service.

Complete information to perform this

procedure is available in the appropriate

operator's manual. Refer to the operator's

manual on your machine.

Loading...

Loading...