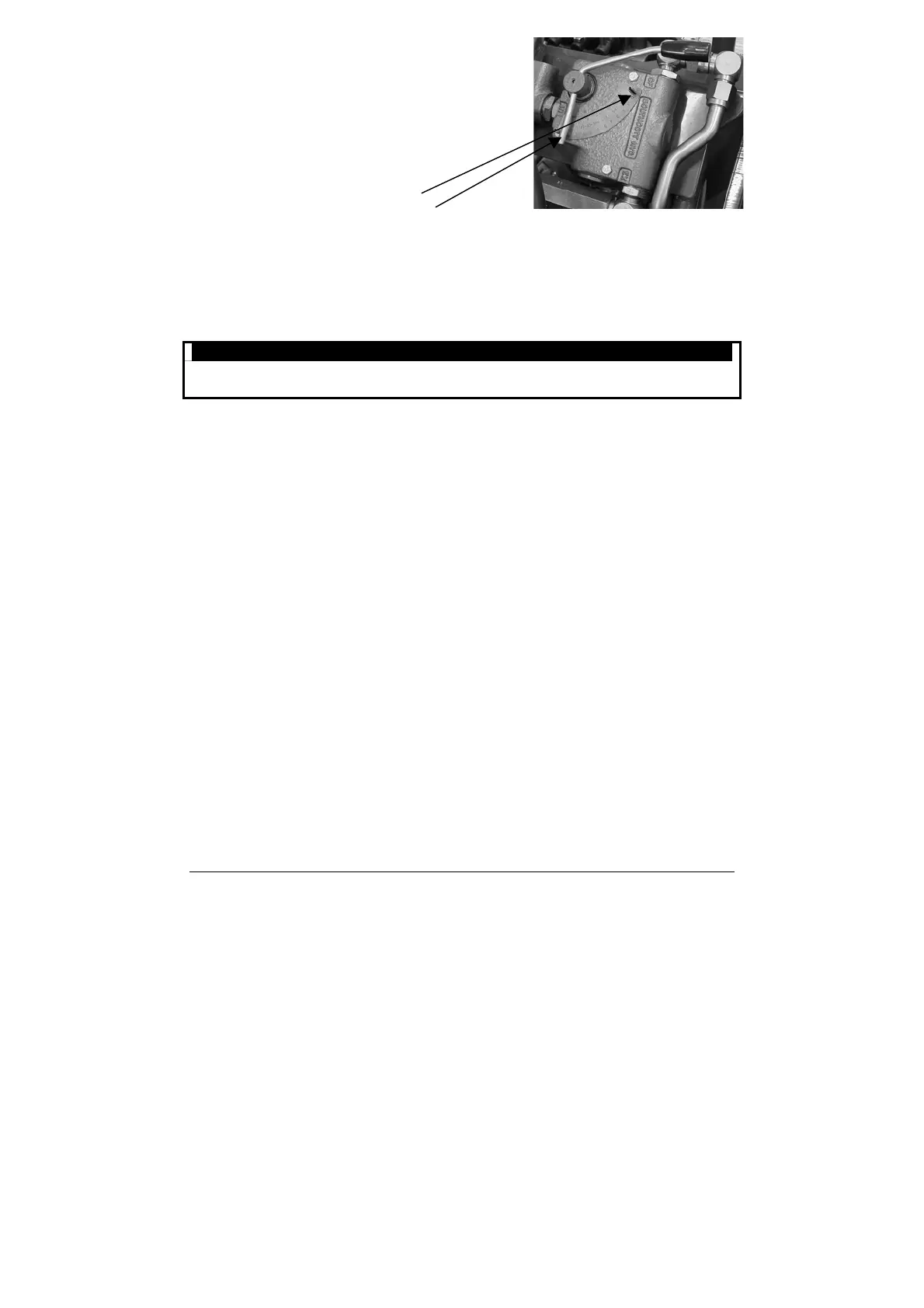

Flow divider control

Move flow divider control to twelve-o’clock

position (normal operating position, as pictured) for

no flow division. When moving control to nine-

o’clock position, flow is diverted to the attachments

and less is available to the wheels and loader arms.

This allows for greater concentration of power

where it’s needed most.

9 O’clock position

12 O’clock position

Starting and stopping the Engine

Starting

Stand on the platform.

Move the auxiliary hydraulics lever to neutral.

Attention

Ensure auxiliary hydraulic lever is in neutral position before starting engine. Aside

from starting difficulties it may cause the attachment may move during starting.

1. Follow instructions on starting engine as detailed in the engine manufacturers

manual.

Stopping

Move the throttle lever to “slow”.

Lower loader arms to the ground.

Turn the ignition key to off.

Note: If the engine has been working hard or is hot, let it idle for a minute before

turning the ignition key “OFF”. This helps cool the engine before it is stopped. In an

emergency, turning the ignition key to “OFF” will stop the engine.

Driving forward or backward

The throttle control regulates the engine speed as measured in rpm (revolutions per

minute). Place the throttle control in the “fast” position for best performance.

Note: Throttle position can be utilised to operate at slower speeds.

Forward

To go forward, slowly push the drive control levers forward.

To go straight, apply equal pressure to both drive control levers.

To turn, decrease pressure on the drive control lever closest to the direction you want

to turn.

The farther you move the drive control levers in either direction, the faster the

machine will move in that direction.

To slow or stop, move or release the drive control levers into neutral. (If released the

control levers should automatically return to neutral).

Dingo 950 Operation & Maintenance Manual

17

Loading...

Loading...