Hydraulic System

Replacing the Hydraulic Filter

Change the hydraulic filter:

After every 500 operating hours

Position the machine on a level surface, lower the

loader arms and turn the ignition key to “OFF” to

stop the engine. Remove the key.

IMPORTANT: Do not substitute with automotive oil

filter or severe hydraulic damage may result.

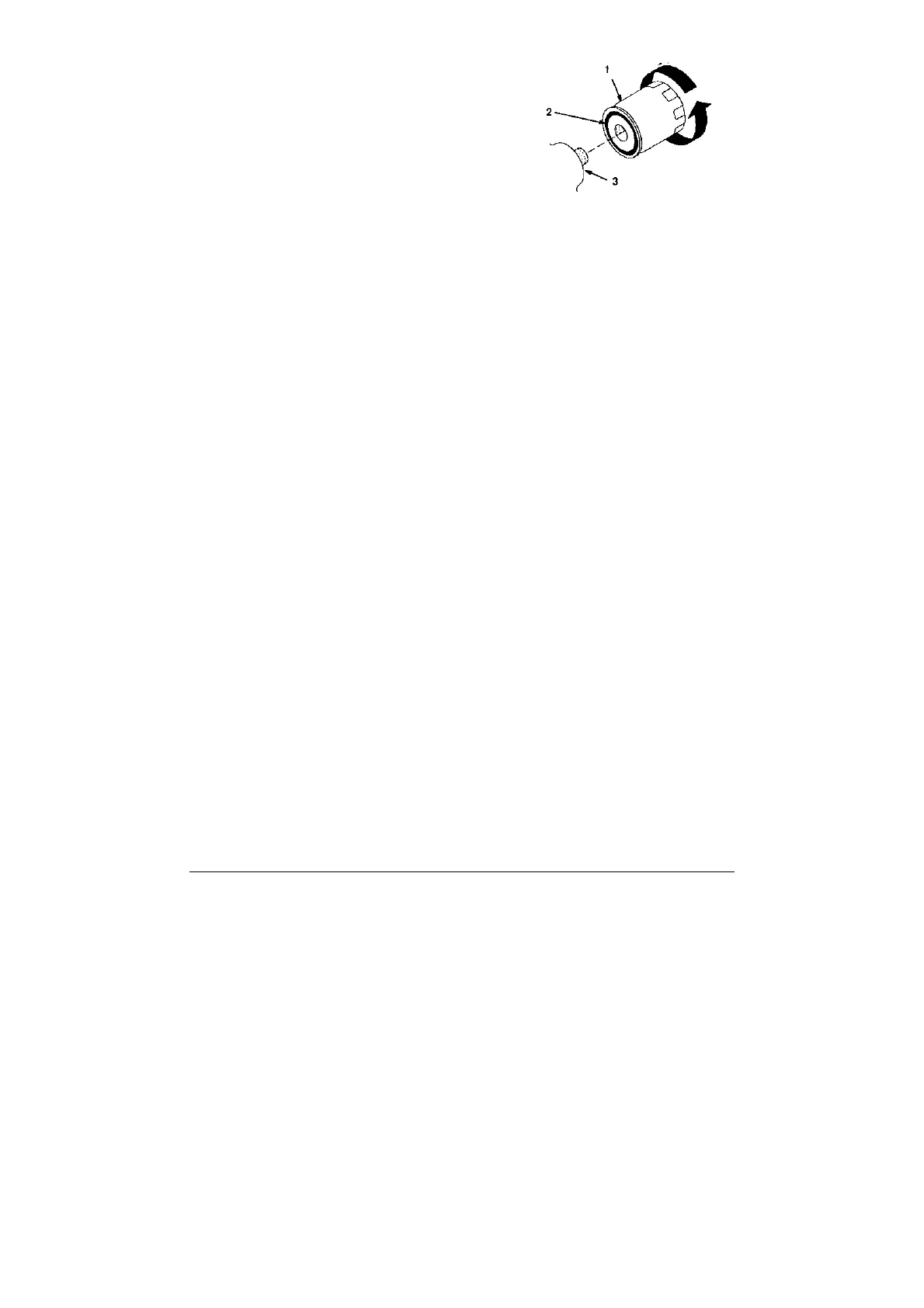

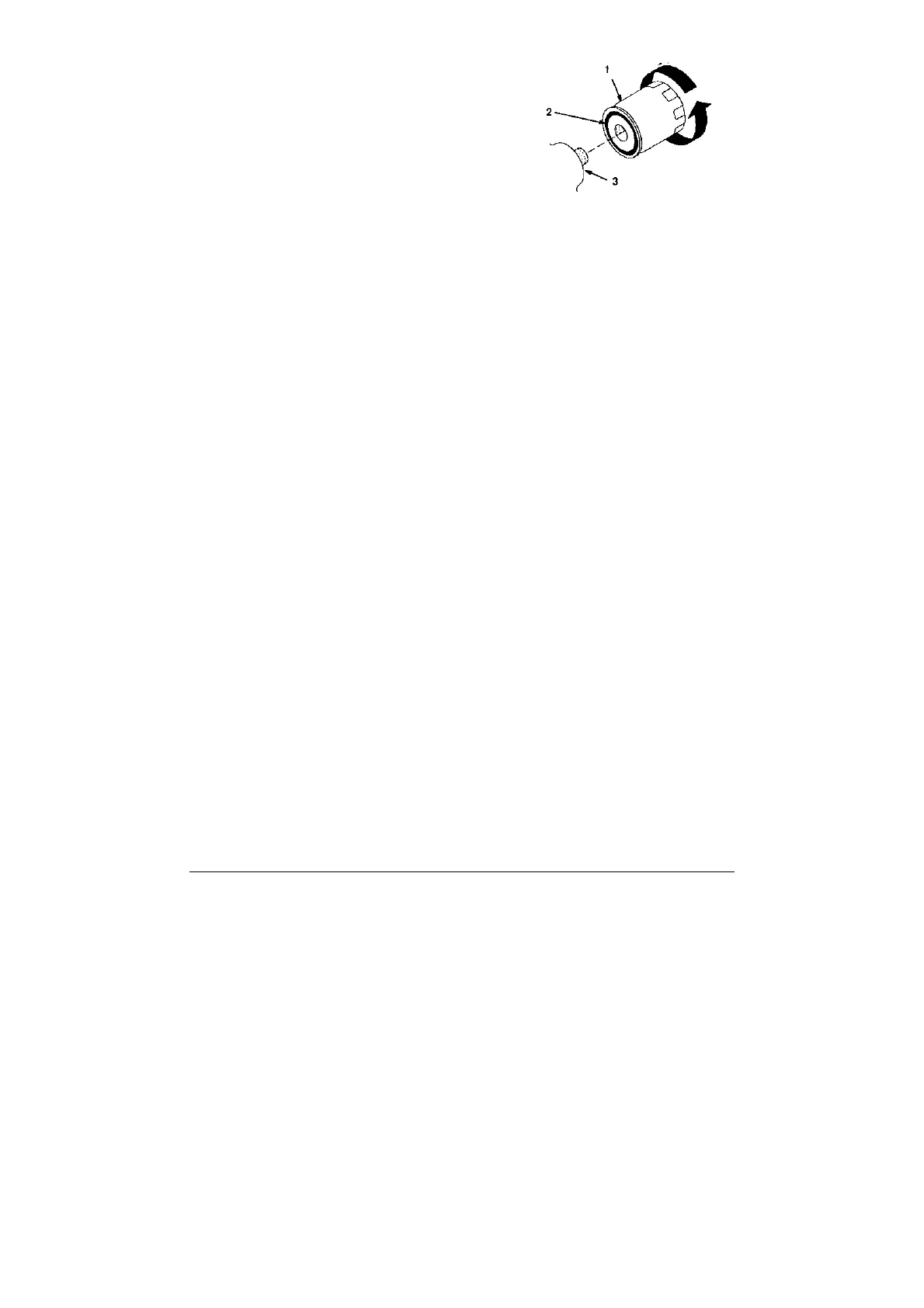

1. Hydraulic filter

2. Gasket

3. Adapter

Remove the old filter and wipe the filter adapter gasket

surface clean.

Apply a thin coat of hydraulic fluid to the rubber gasket on the replacement filter.

Install replacement hydraulic filter. Tighten clockwise until the rubber gasket contacts

the filter adapter, then tighten the filter an additional ½ turn.

Clean up any spilt fluid.

Start engine and let run for about two minutes to purge air from the system. Stop the

engine and check for leaks.

Check fluid level in hydraulic tank and add oil to raise level to 75mm below the top of

the tank. DO NOT OVER FILL.

Changing the Hydraulic Fluid

Change the hydraulic fluid:

After every 500 operating hours

Position the machine on a level surface, lower the loader arms and turn the ignition

key to “OFF” to stop the engine. Remove the key.

IMPORTANT: Do not substitute with automotive oil filter or severe hydraulic

damage may result.

Place large drain pan under the machine that can hold at least 70 litres.

Remove the drain plug from the bottom of the hydraulic tank and allow the fluid to

completely drain out.

Remove the tank top and wipe out the inside of the tank. Note if any foreign objects

are there. If anything unusual is found, consult your Dingo service centre or a

hydraulic expert.

Install the drain plug.

Fill the hydraulic tank with approximately 57litres of H68 hydraulic oil.

Note: Dispose of used oil in accordance with local authority regulations.

Only use H68 oil, use of other oil grades can cause loss of hydraulic power, or

damage to machine.

Check hydraulic lines

After every 100 operating hours, check hydraulic lines and hoses for leaks, loose

fittings, kinked lines, loose mounting supports, wear, weather and chemical

deterioration. Replace all moving hydraulic hoses every 1500 hours or two years,

Dingo 950 Operation & Maintenance Manual

26

Loading...

Loading...