18

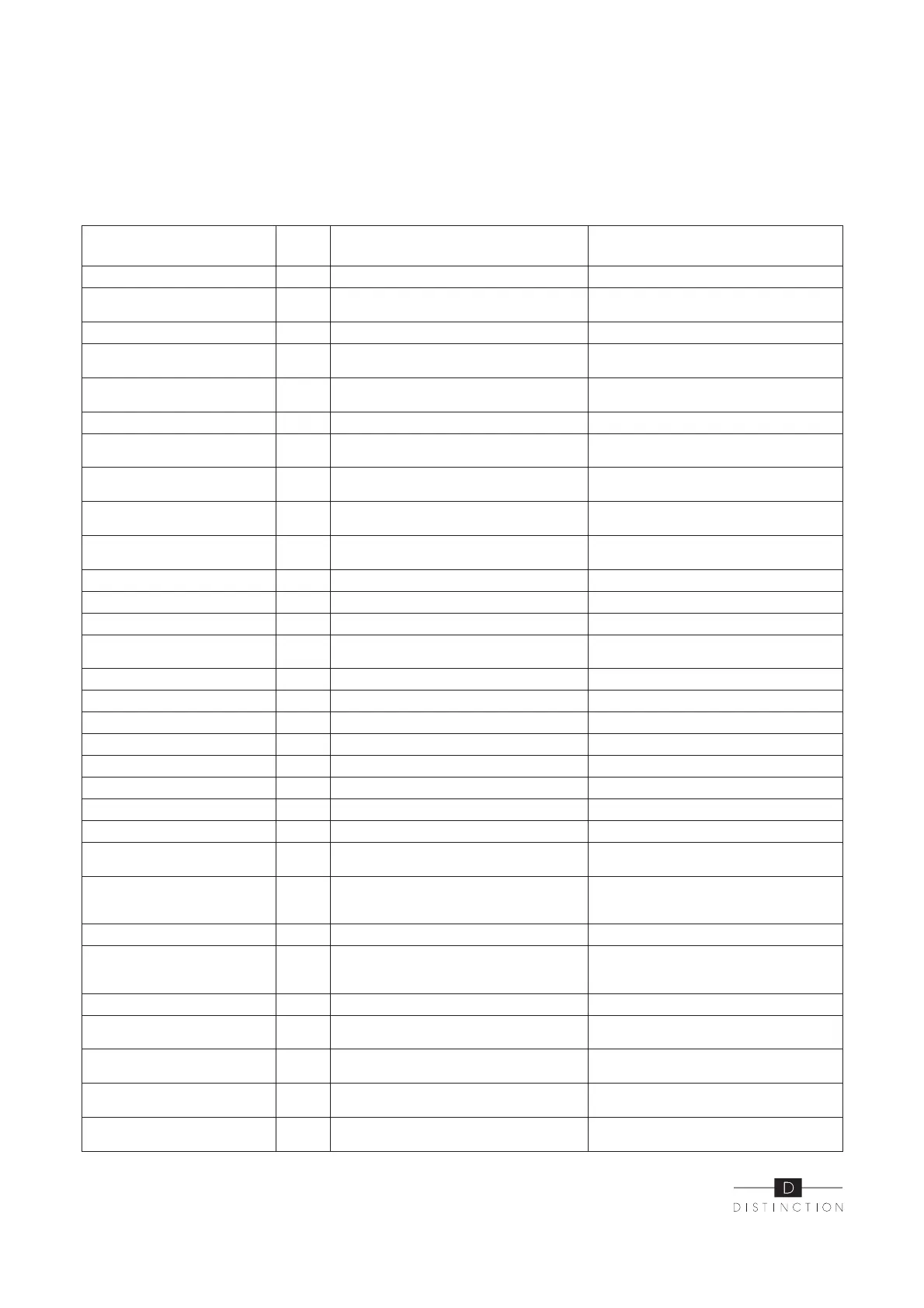

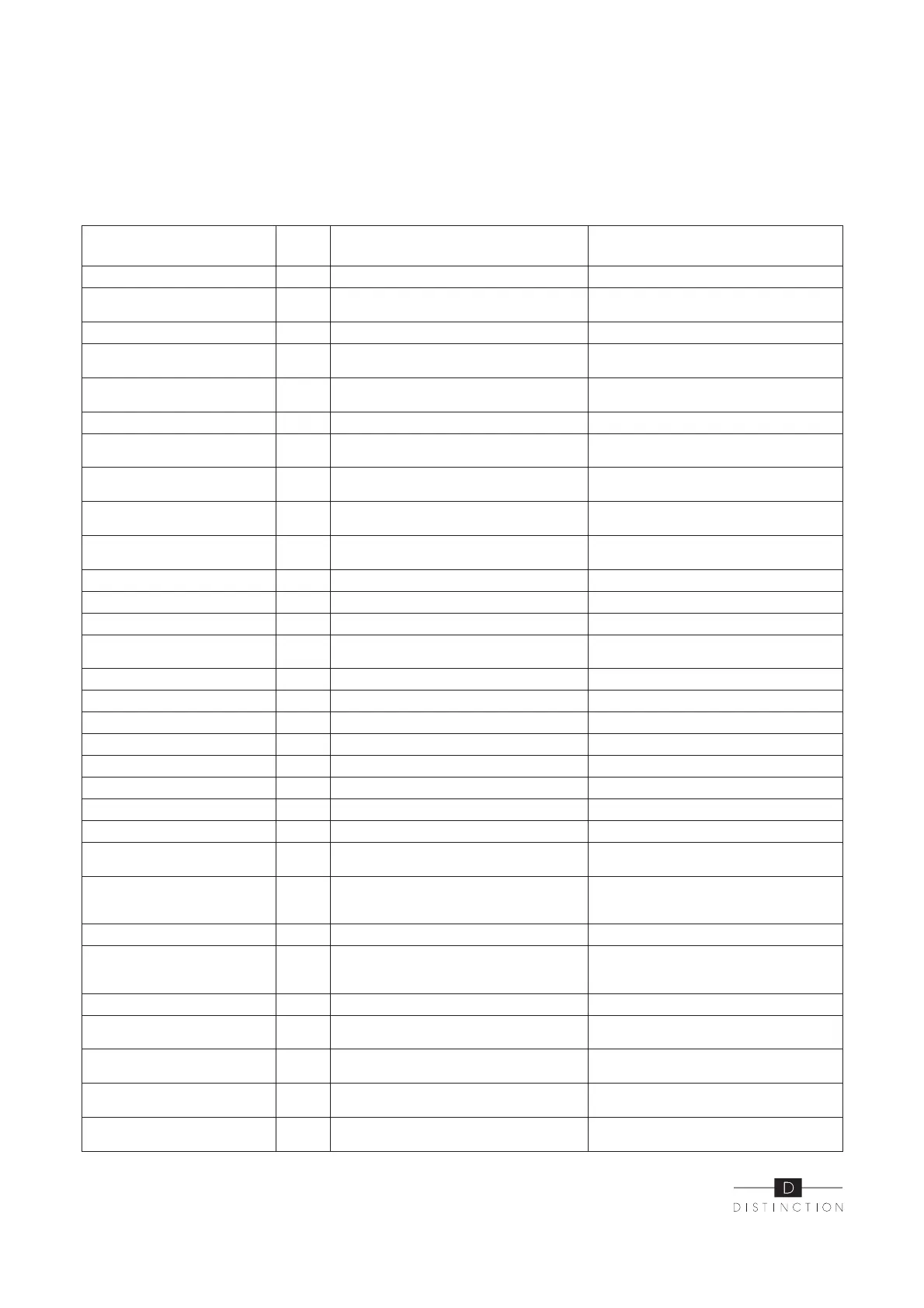

Frequency conversion board fault table :

Protect/fault

Fault

display

Reason Elimination methods

Drv1 MOP alarm F01 MOP drive alarm Recovery after the 150s

F02

Frequency conversion board and main

board communication failure

Check the communication connection

IPM protection F03 IPM modular protection Recovery after the 150s

Comp. driver failure F04 Lack of phase, step or drive hardware damage

Check the measuring voltage check

frequency conversion board hardware

DC fan fault F05

Motor current feedback open circuit or short

circuit

Check whether current return wires

connected motor

IPM overcurrent F06 IPM Input current is large Check and adjust the current measurement

Inverter DC overvoltage F07

DC bus voltage > Dc bus over-voltage protec-

tion value

Check the in put voltage measurement

Inverter DC lessvoltage F08

DC bus voltage < Dc bus over-voltage protection

value

Check the input voltage measurement

Inverter input lessvolt. F09

The input voltage is low, causing the inputcur-

rent is high

Check the input voltage measurement

Inverter input Overvolt. F10

The input voltage is too high, more than outage

protection current RMS

Check the input voltage measurement

Inverter sampling Volt. F11 The input voltage sampling fault Check and adjust the current measurement

Comm. error DSP-PFC F12 DSP and PFC connect fault Check the communication connection

Input over cur. F26 The equipment load is too large

PFC fault F27 The PFC circuit protection

Check the PFC swit ch tube short circuit

or not

IPM over heating F15 The IPM module is overheat Check and adjust the current measurement

Weak magnetic warn F16 Compressor magnetic force is not enough

Inverter input out phase F17 The input voltage lost phase Check and measure the voltage adjustment

IPM sampling cur. F18 IPM sampling electricity is fault Check and adjust the current measurement

V temp. Probe Fail F19 Sensor is short circuit or open circuit Inspect and replace the sensor

Inverter overheating F20 The transducer is overheat Check and adjust the current measurement

Inverter overheating Warn F22 Transducer temperature is too high Check and adjust the current measurement

Comp. over cur. warn F23 Compressor electricity is large The compressor over-current protection

Pressure sensor fault PP The pressure sensor is broken

Check or change the pressure sensor or

pressure

Fan Motor1 fault F031

1. Motor is in locked-rotor state

2.The wire connection between DC-fan motor

module and fan motor is in bad contact

1.Change a new fan motor

2.Check the wire connection and make sure

they are in good contact

Low AT Protection TP Ambient temp is too low

Fan motor2 fault F032

1. Motor is in locked-rotor state

2.The wire connection between DC-fan motor

module and fan motor is in bad contact.

1.Change a new fan motor

2.Check the wire connection and make sure

they are in good contact

Communication fault Speed control module and main

Communication fault (speed

control module)

E081

Speed control module and main board commu-

nication fail.

Check the communication connection.

Input over cur. warn F24 Input current is too large Check and adjust the current measurement

EEPROM error warn F25 MCU error

Check whether the chip is damaged Replace

the chip

V15V over/undervoltage fault F28 The V15V is overload or undervoltage

Check the V15V input voltage in range

13.5v~16.5v or not

Loading...

Loading...