I

I

I

••

I

II

INSTALLATION

NOTE: All

"left",

"right",

"front",

and

"rear"

directions in this manual are as viewed when

facing left saw guide arm clamping knob.

LOCATION

(1)

Position

machine

to

allow

room

for

feeding

and

removing

stock

with

maximum

convenience

.

(2)

Allow

sufficient

space

for

head

elevation,

door

opening,

lubrication

and

maintenance

procedures.

(3)

Approximate

machine

floor

dimensions

are

78

inches

(1980

mm)

wide

by

57

inches

(1450

mm)

deep.

Approximate

head

down

height

is

53-1/8

inches

(1350 mm);

head

up

height

is

72-1/2

inches

(1840 mm).

Refer

to

Figs.

1-3

for

additional

dimensions

.

OSHA

NOTICE!

OSHA

Regulation

No.

1910.212

(8).

Machines

designed

for fixed location shall be securely

anchored to prevent walking or moving.

UNPACKING

(1)

Carefully

remove

all

crating,

coverings,

strapping,

etc.

(2)

Remove

wires

used

to

secure

doors

and

wheels

.

CAUTION: Do not remove drive motor blocking or

bracket holding head to base until the

unit has been lifted to its permanent

location.

(3)

Check

machine

for

broken

or

damaged

parts.

Refer

to

this

manual's

inside

front

cover

for

damage

claim

procedures

.

CLEANING

(1)

A

rust

preventive

coating

has

been

applied

to

all

exposed

bare

metal.

Use

solvent

to

remove

this

coating.

3

LIFTING

(1)

The

machine

and

stock

unloading

table

can

be

moved

into

position

with

a

fork

lift

truck

or

overhead

hoist.

(2)

Spread

lift

truck

forks

for

even

weight

distri-

bution

to

protect

against

stress

on

machine

frame.

Hoist

slings

should

be

padded

.

NOTE:

The

stock unloading table

and

conveyors

(if supplied) can

be

lifted by

either

method.

Relocation Procedures

Should

machine

relocation

become

necessary

at

a

later

date,

it

will

be

extremely

important

to

protect

against

undue

machine

frame

stress

.

Move

machine

by

fork

lift

truck

and

observe

the

following

precautions:

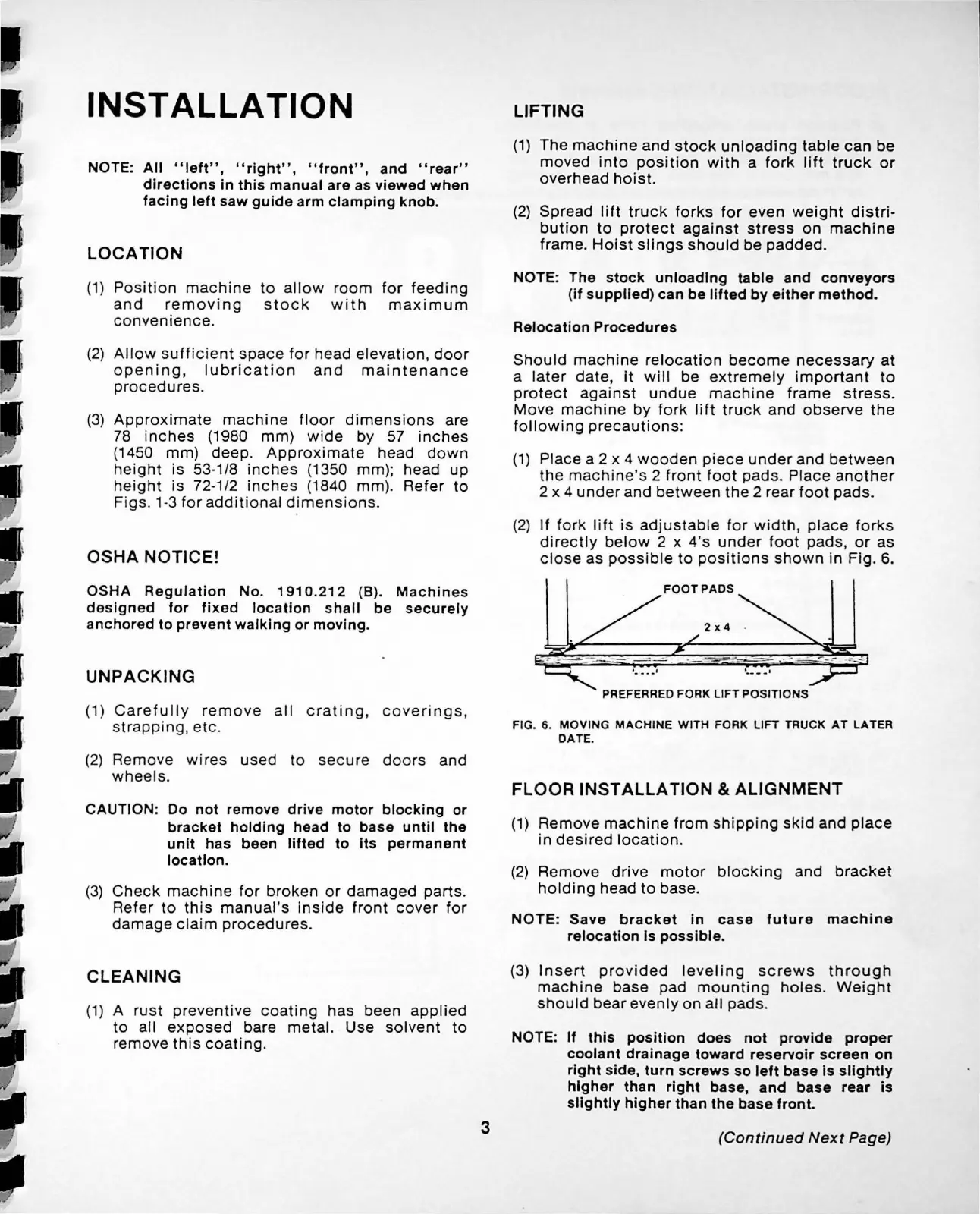

(1)

Place

a 2 x 4

wooden

piece

under

and

between

the

machine's

2

front

foot

pads

.

Place

another

2 x 4

under

and

between

the

2 rear

foot

pads.

(2)

If

fork

lift

is

adjustable

for

width,

place

forks

directly

below

2 x 4's

under

foot

pads,

or

as

close

as

possible

to

positions

shown

in

Fig.

6.

FOOTPADS

PREFERRED FORK

LIFT

POSITIONS

FIG. 6.

MOVING

MACHINE

WITH

FORK LIFT TRUCK

AT

LATER

DATE

.

FLOOR INSTALLATION &

ALIGNMENT

(1)

Remove

machine

from

shipping

skid

and

place

in

desired

location.

(2)

Remove

drive

motor

blocking

and

bracket

holding

head

to

base.

NOTE:

Save

bracket

in

case

future

machine

relocation is possible.

(3)

Insert

provided

leveling

screws

through

machine

base

pad

mounting

holes

.

Weight

should

bear

evenly

on

all

pads.

NOTE:

If

this position does not provide proper

coolant drainage toward reservoir screen on

right side, turn screws so left base is slightly

higher than right base,

and

base rear is

slightly higher than the base fronL

(Continued

Next

Page)

Loading...

Loading...