20

Fault location

Maintenance schedule

When the machine is in storage for a long time, drain fuel from the fuel –

tank and carburetor, as follows: Drain all fuel from the fuel tank. Dispose of

properly and in accordance with all local laws.

Remove the spark plug and a few drops of oil into the spark plug hole. –

Then, pull the starter gently, so that oil covers the engine inside and tighten

the spark plug.

Clear dirt or dust from the cutter blade and outside of engine, wipe them with –

a oil-immersed cloth and keep the machine in a place as dry as possible.

Drain fuel

Humidity

STORAGE

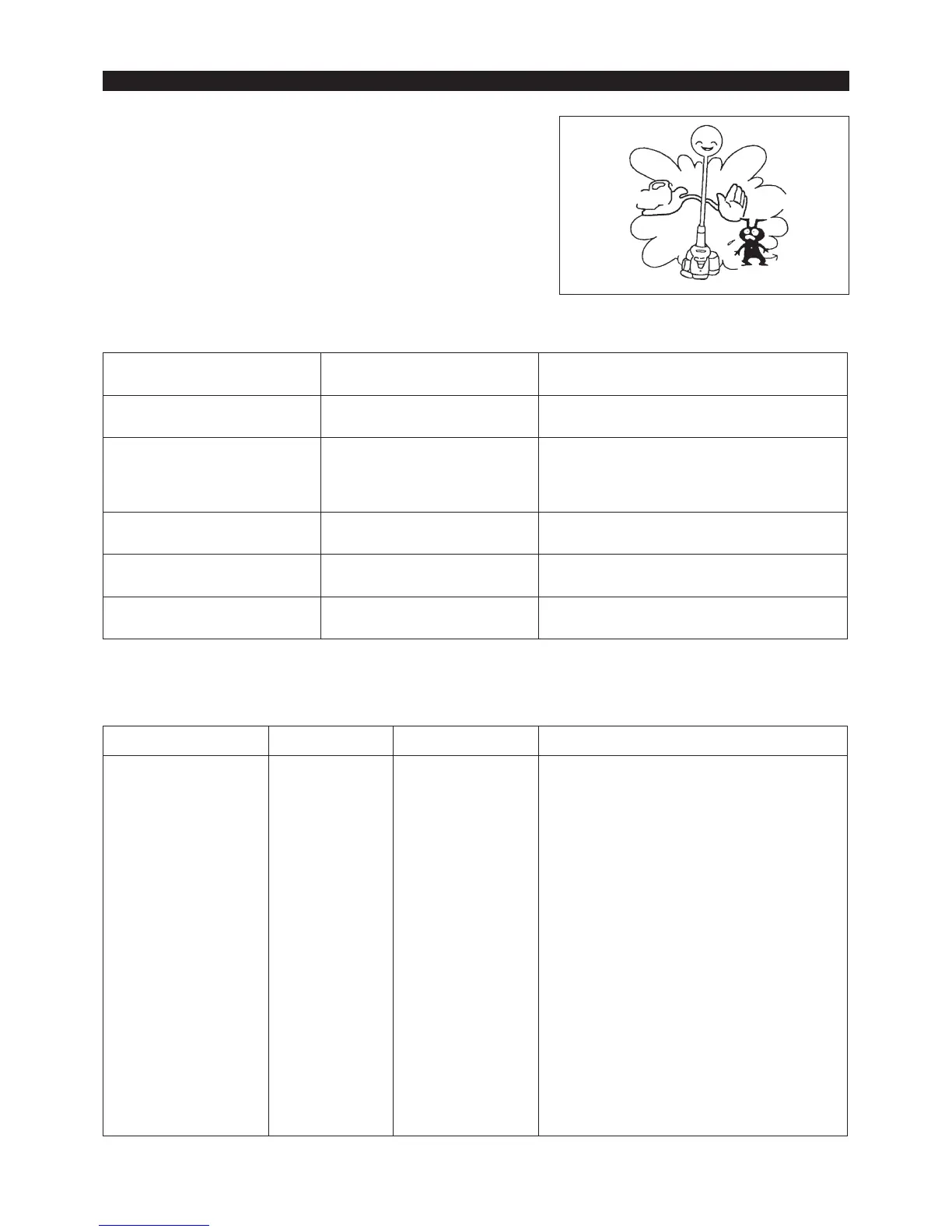

Fault System Observation Cause

Engine not starting or with

difculty

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark I-O switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank lled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty

Compression No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Warm start problems Tank lled ignition spark

existing

Carburetor contaminated, must be cleaned

Engine starts but dies Fuel supply Tank lled Incorrect idling adjustment, carburetor contaminated

Fuel tank vent defective, fuel supply line interrupted,

cable or I-O switch faulty

Insufcient performance Several systems may

simultaneously be

affected

Engine idling poor Air lter contaminated, carburetor contaminated, mufer

clogged, exhaust duct in the cylinder clogged

General Engine assembly, screws and nuts Visual inspection for damage and tightness

Check for general condition and security

After each refuelling Control lever

I-O switch

Functional check

Functional check

Daily Air lter

Cooling air duct

Cutting tool

Idling speed

To be cleaned

To be cleaned

Check for damage and sharpness

Inspection (cutting tool must not move)

Weekly Spark plug

Mufer

Inspection, replace if necessary

Check and if necessary clean the opening

Quarterly Suction head

Fuel tank

To be replaced

To be cleaned

Shutting down procedure Fuel tank

Carburetor

Empty fuel tank

Operate until engine runs out of fuel

Loading...

Loading...