Power Train Disassembly & Assembly

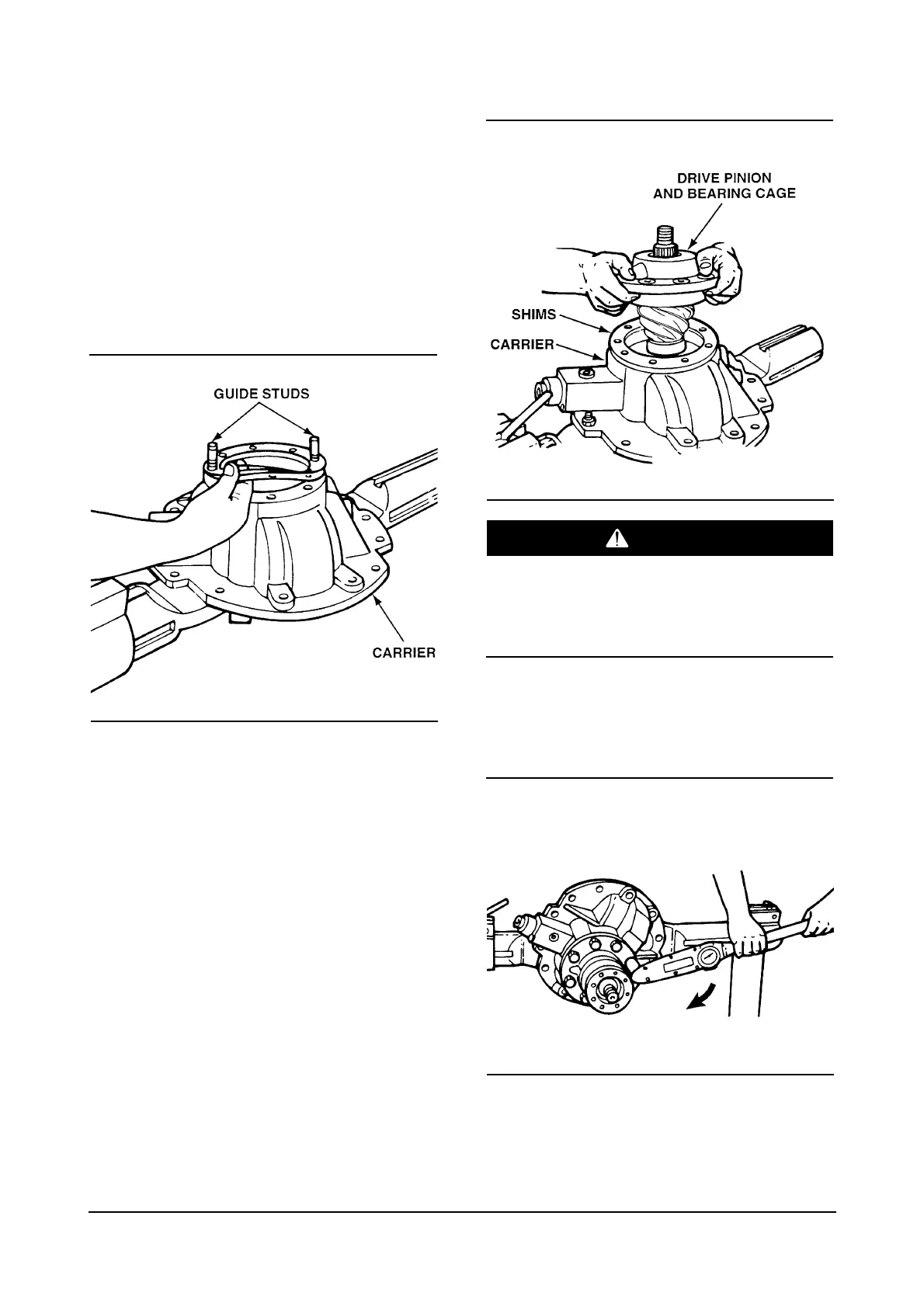

Installing the Drive Pinion,

Bearing Cage and Shim Pack

into the Carrier

NOTE : If a new drive pinion and ring gear set is

installed, or if the depth of the drive pinion has to be

adjusted, calculate the thickness of the shim pack.

Refer to the procedure “Adjusting Shim Pack

Thickness for the pinion Cage (Depth of Pinion)” on

page 24.

1. Select the correct shim pack between the bearing

cage and carrier.

2. Apply Loctite® 518 Gasket Eliminator to face of

carrier.

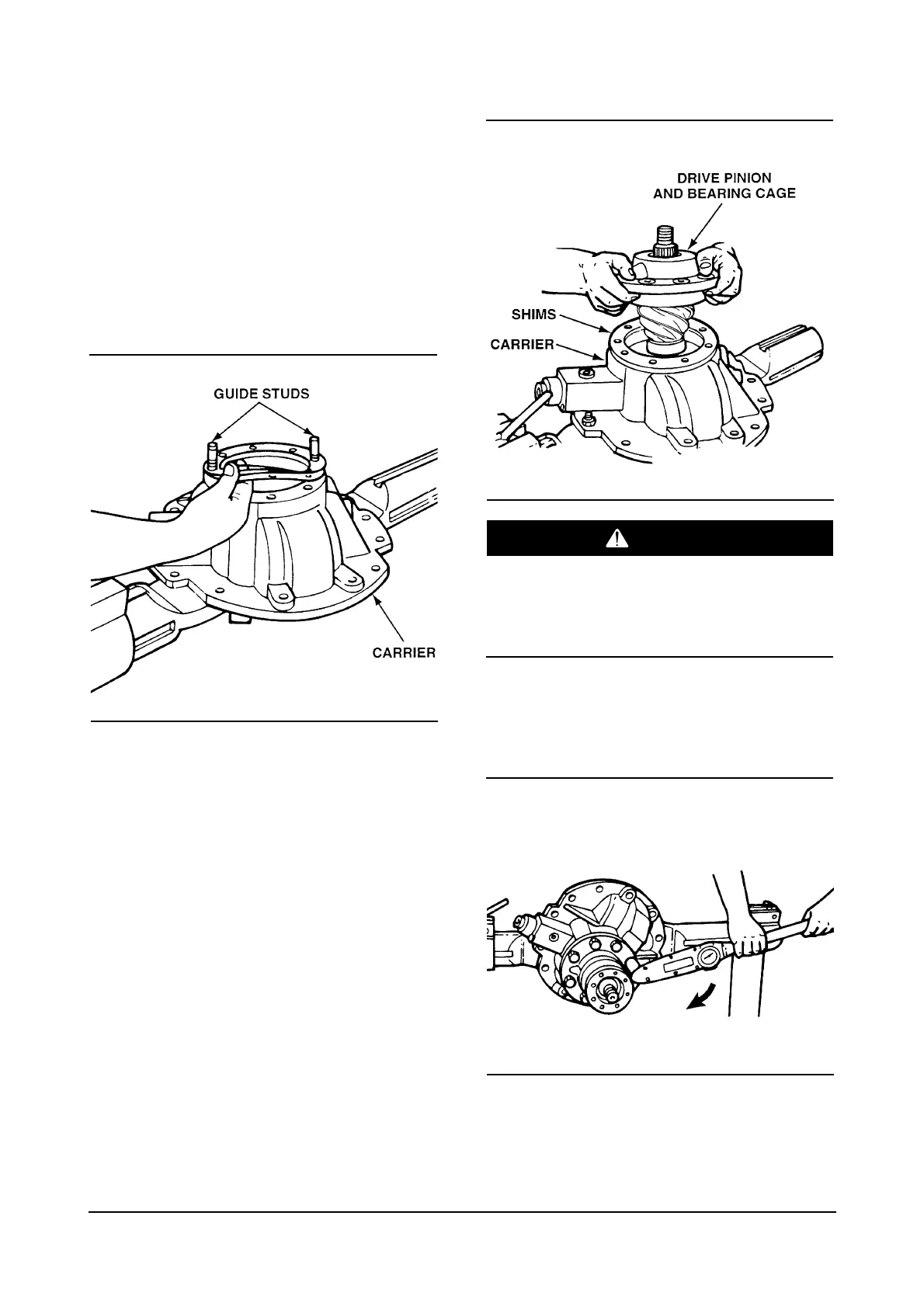

3. Align the oil slots in the shims with oil slots in the

bearing cage and carrier. The use of guide studs

will help align the shims.

NOTE : If the pack is made from different thickness

shims, install the thinnest shims on both sides of the

pack for maximum sealing.

4. Apply Loctite® 518 Gasket Eliminator to top of

shim pack.

Do not hit steel parts with a steel hammer during

removal and disassembly procedures. Striking

parts with a hammer can cause the parts to break

and result in serious personal injury.

5. Install the drive pinion and bearing cage into the

carrier. If necessary, use a rubber, plastic or

leather mallet to hit the assembly into position.

6. Install the bearing cage to carrier capscrews and

washers. Tighten capscrews to a torque of 70 to

110 lb•ft (90 to 150 N•m)

Loading...

Loading...