Power Train Disassembly & Assembly

Installing Tight Fit Yokes and

the POSE

TM

Seal

CAUTION : Make sure that the seal lips are clean

and free from dirt and particles that can cause a leak

between the yoke and the POSE

TM

seal.

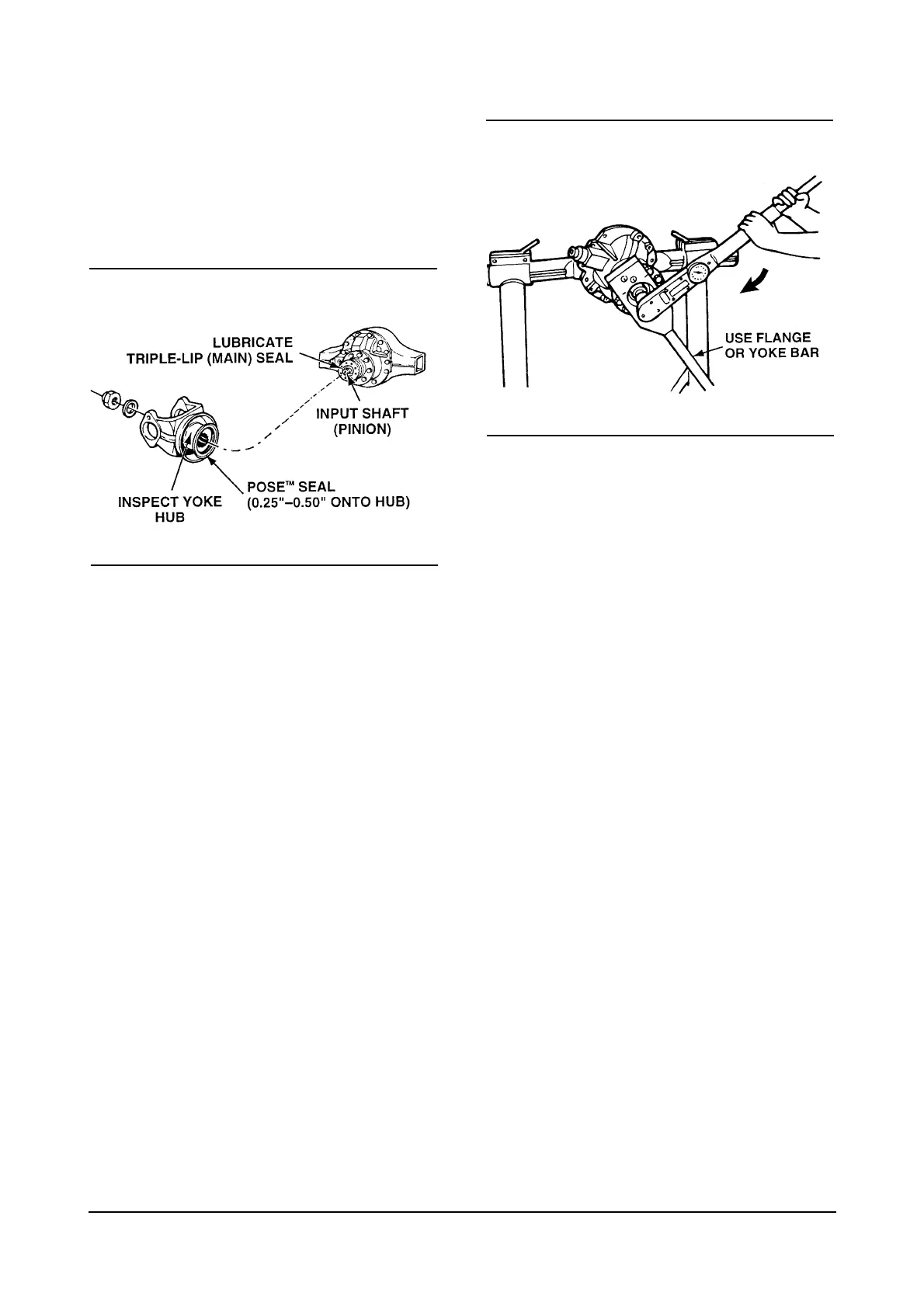

1. Inspect all surfaces of the yoke hub for damage.

2. Apply axle lubricant to the seal.

If carrier uses a POSE

TM

element, install a new

POSE tm seal as follows:

3. Lightly lubricate the yoke journal with same

lubricant used in the axle housing.

4. Partially install the POSE

TM

seal onto the yoke to

1/4 inch-1/2 inch (6.4 - 12.7 mm) as shown

NOTE : Do not install the POSE

TM

seal all the way

against the yoke shoulder. This seal is designed to

position itself as yoke is installed.

5. Lubricate the yoke again with the same lubricant

used in the axle housing before installing the yoke

onto the drive pinion.

6. Slide the yoke over the input shaft pinion. Align the

yoke splines with the shaft splines.

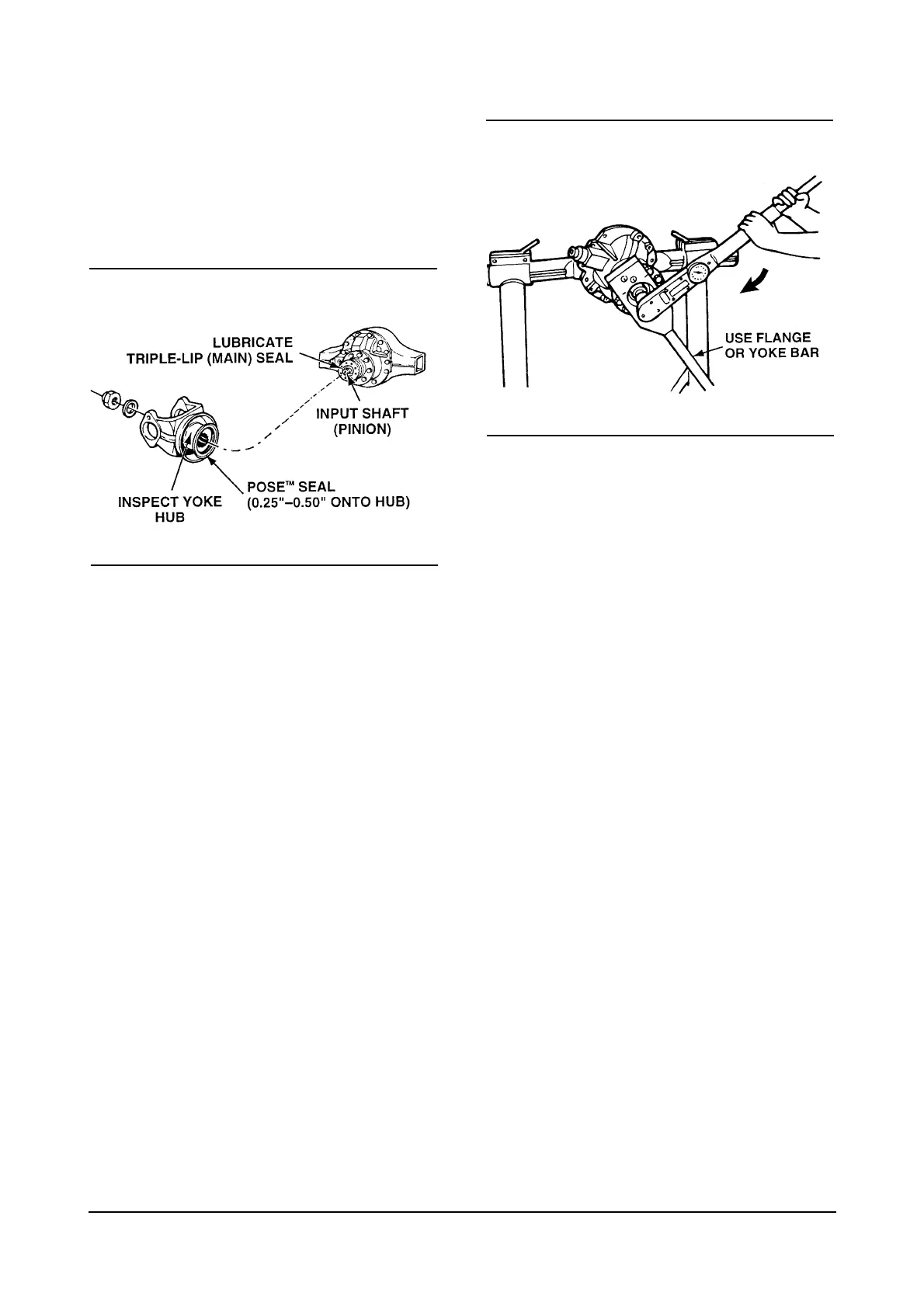

CAUTION : Do not use a hammer or mallet to install

the yoke to the input pinion shaft. Using a hammer or

mallet can damage the yoke flange.

CAUTION : Do not install tight fit yokes on shafts

using a hammer or mallet. Using a hammer or mallet

can damage the yoke.

7. Install the input yoke flange onto the drive pinion

shaft. The yoke must be fully seated against the

outer differential bearing before the nut is torqued

to specifications.

8. Install the drive pinion nut on the input pinion shaft

and against the yoke collar. Tighten the nut against

yoke collar to a torque of 922 to 1132 lb•ft (1250 to

1535 N•m)

Assemble the Main

Differential and Ring Gear

Assembly

CAUTION : Do not press a cold ring gear on the

flange case half. A cold ring gear will damage the

case half because of the tight fit. Metal particles

between the parts will cause gear runout that

exceeds the specification of 0.008 inch (0.200 mm).

1. Expand the ring gear by heating the gear in a tank

of water to a temperature of 160˚F to 180˚F (71˚C-

82˚C) for 10 to 15 minutes. Do not use an open

flame such as a torch to heat the ring gear.

28

Loading...

Loading...