Power Train Disassembly & Assembly

Wear safe clothing and gloves for protection from

injury when working with the hot ring gear.

2. Safely lift the ring gear from the tank of water

using a lifting tool.

3. Install the ring gear on the flange case half

immediately after the gear is heated. If the ring

gear does not fit easily on the case half, heat the

gear again. Repeat step 1.

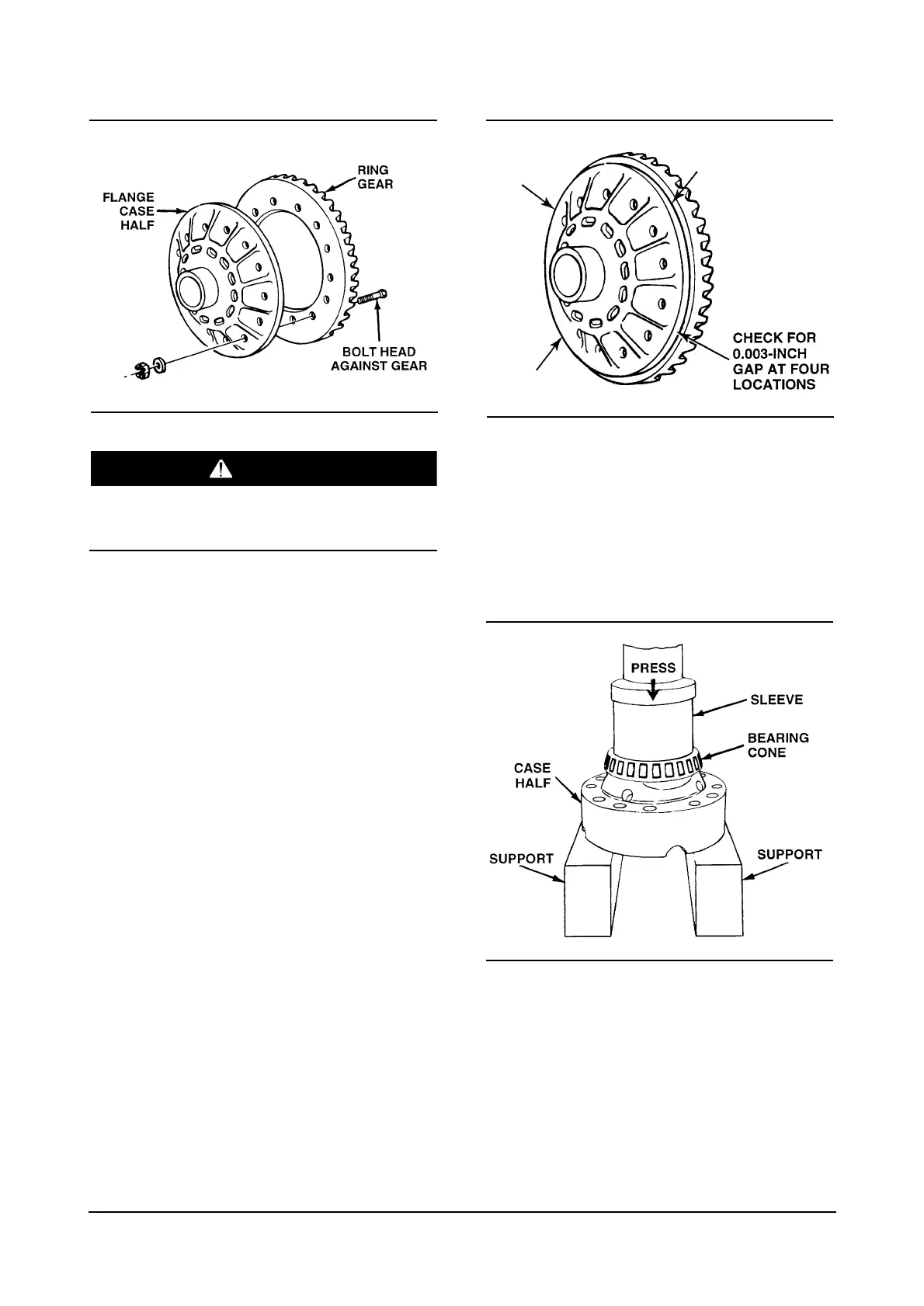

4. Align fastener holes of the ring gear and flange

case half. Rotate the ring gear as needed.

5. If rivets were used to hold the ring gear to the

flange case half, replace them with bolts, nuts and

washers.

6. Install the bolts, nuts and washers that hold the

ring gear to the flange case half. Install the bolts

from the gear side of the assembly. The bolt

threads must be installed from the inside face of

the ring gear. The nuts with washers are tightened

from the back of the ring gear.

7. Tighten the bolts and nuts to a torque of 196 to

262 lb•ft (265 to 355 N•m)

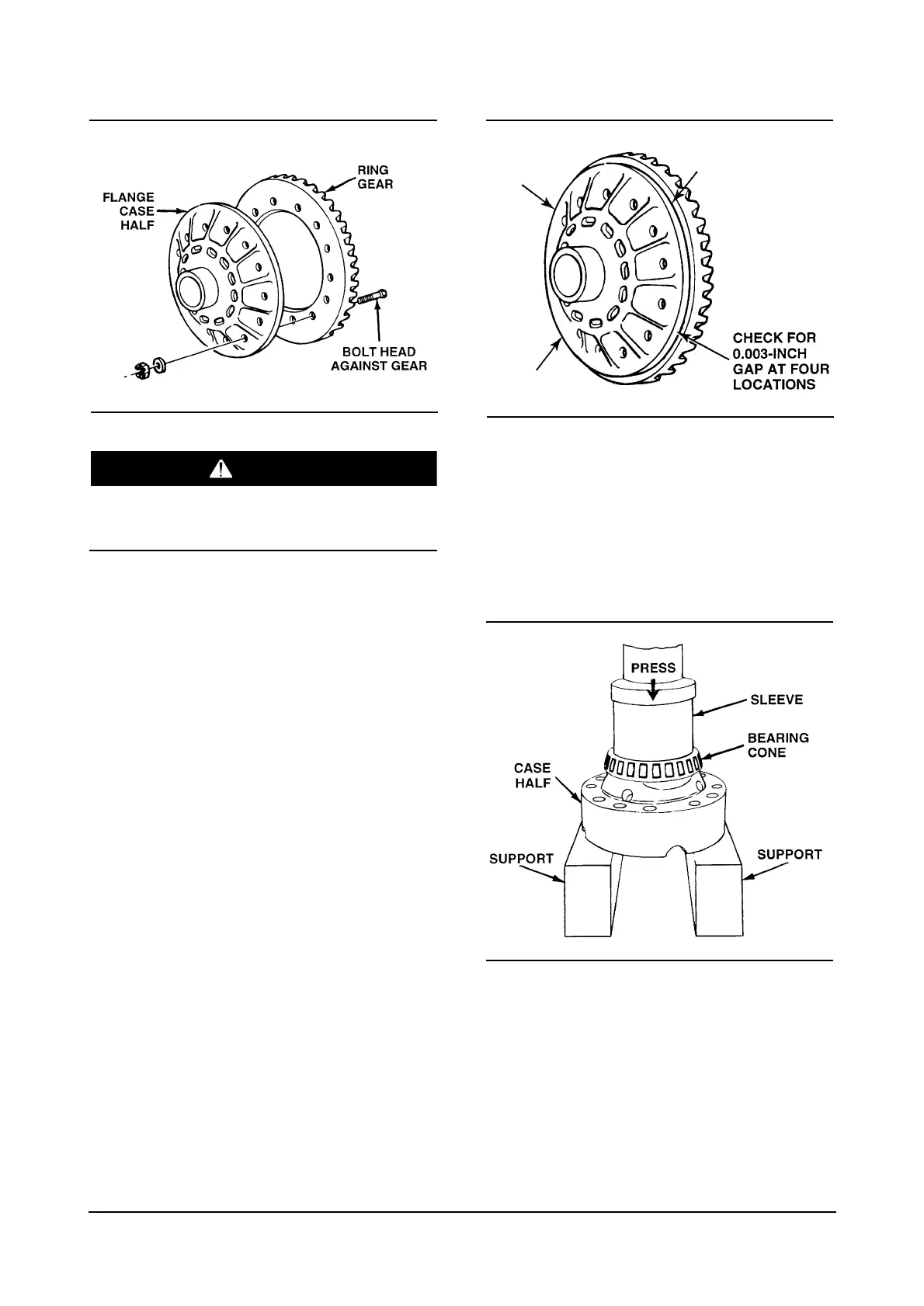

a. After the bolts are installed, inspect for gaps

between the back surface of the ring gear and the

case flange. Use an 0.080 mm (0.003 inch) feeler

gauge and inspect at four points around the

assembly.

b. Inspect the flange case half and ring gear for the

problem that causes the gap. Repair or replace

parts.

c. After the parts are repaired or replaced, assemble

the ring gear on the flange case half. Repeat this

procedure starting on page 28, and these steps a

through c.

8. Install the bearing cones on both of the case

halves. Use a press and sleeve of the correct size.

Loading...

Loading...