Vehicle Systems Disassembly & Assembly 56

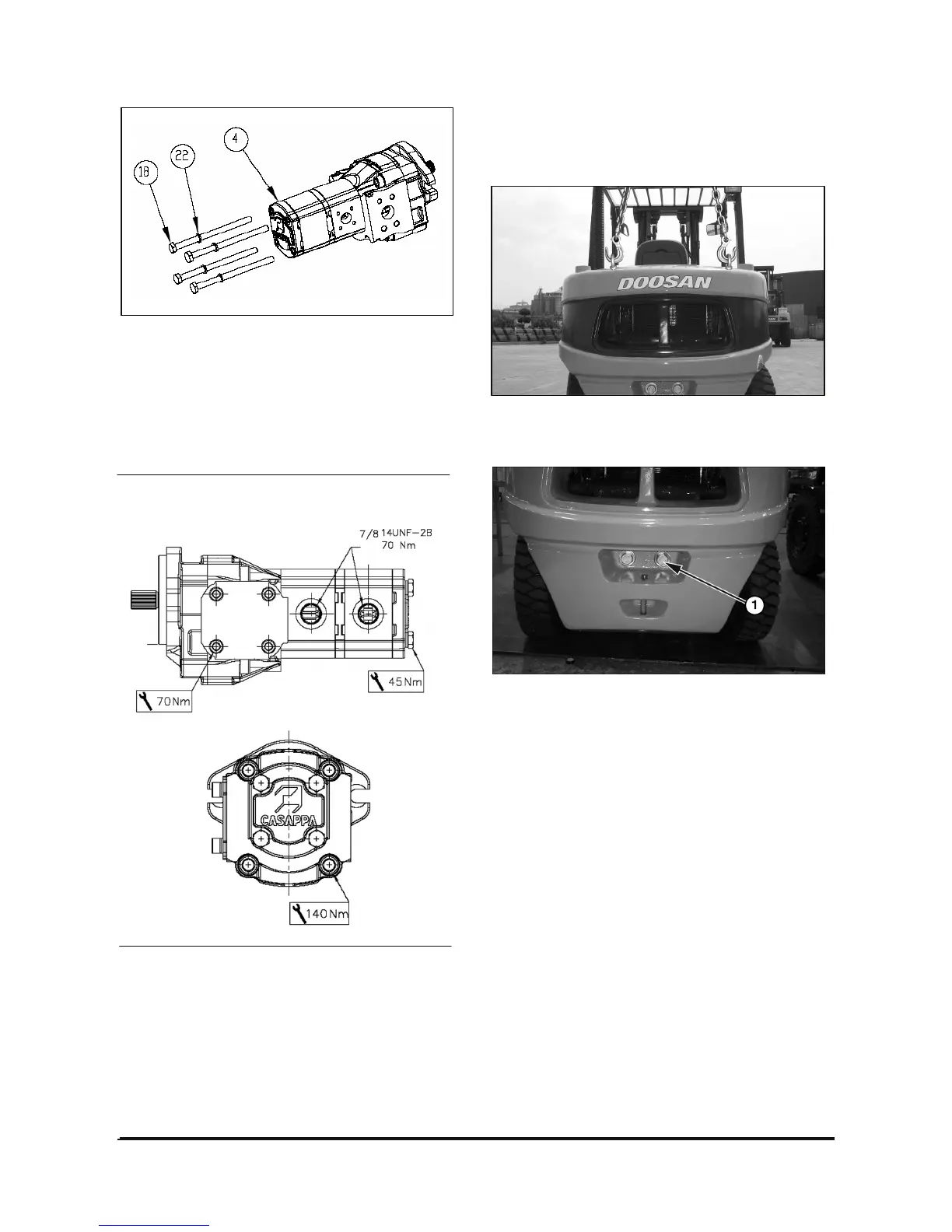

6. Tighten the bolt (18) with washer (22) in a cross

pattern to torque valve of 45Nm.

Check that the pump rotate freely when the

driving shaft is turned by hand. If not a thrust plate

seal may be pinched.

Reference

PIC.23 Torque configuration for hydraulic pump

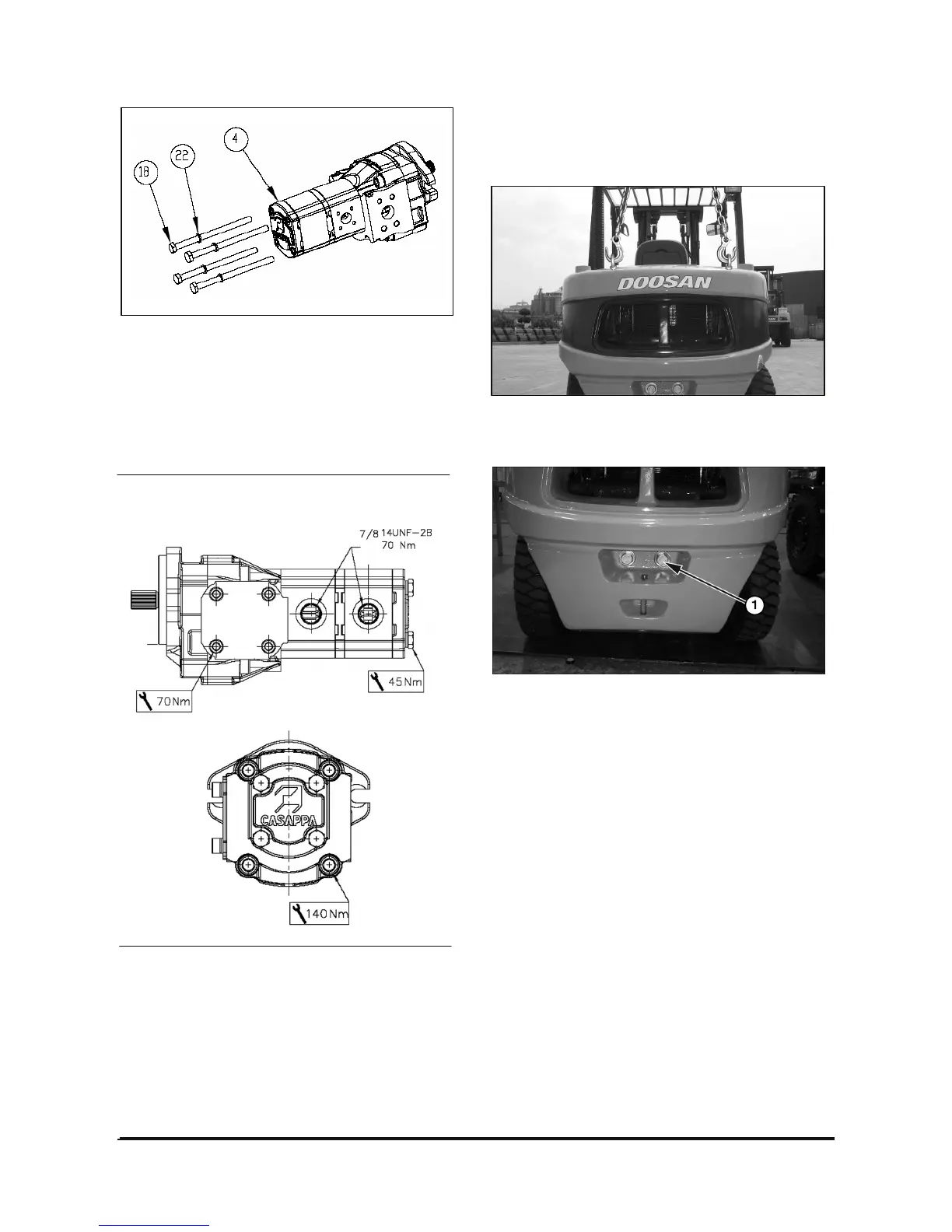

Counterweight

Remove And Install Counterweight

1. Install two eyebolts in the counterweight. Fasten a

hoist to the eyebolts as shown.

2. Remove two bolts (1), washers that hold the

counterweight to the frame. Remove the

counterweight. The weights of the different

counterweight go from a minimum of 1830 kg

(3630 lb) to a maximum of 3120 kg (5170 lb).

NOTE: The following steps are for installation of the

counterweight.

3. Install two eyebolts in the counterweight. Fasten a

hoist to the eyebolts.

4. Put the counterweight in position on the frame

and install bolts (1), washers that hold the

counterweight in place. Tighten torque : 600

± 50

N•m (442

± 37 lb•ft).

Loading...

Loading...